Patents

Literature

37results about How to "Meet the needs of quality control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light source alternate strobe synchronous camera shooting method and vision detection system

InactiveCN102780845APrecise visual informationEasy to observeTelevision system detailsWelding/cutting auxillary devicesImaging processingShutter

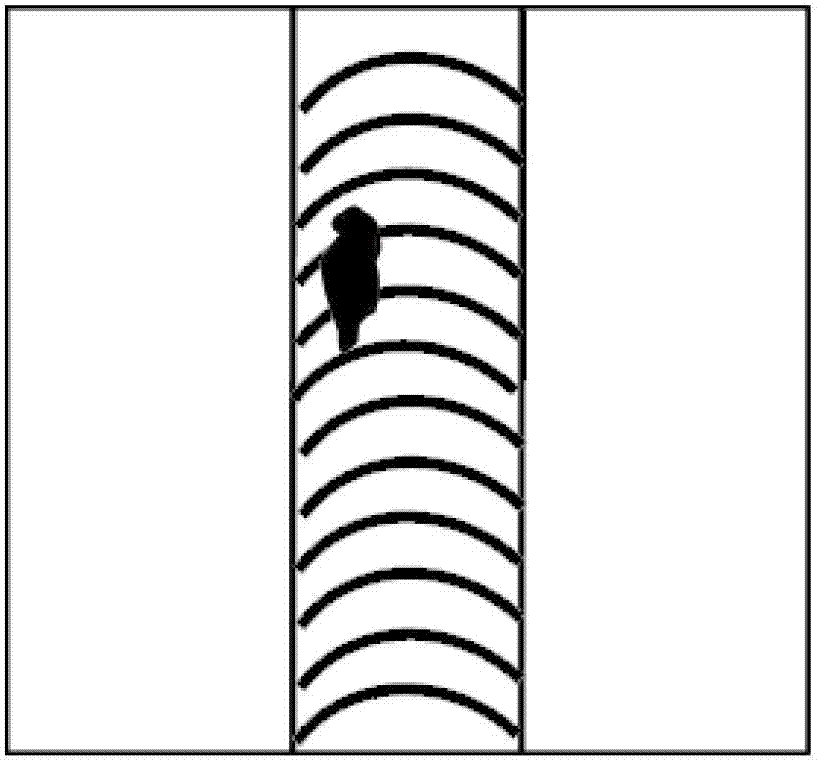

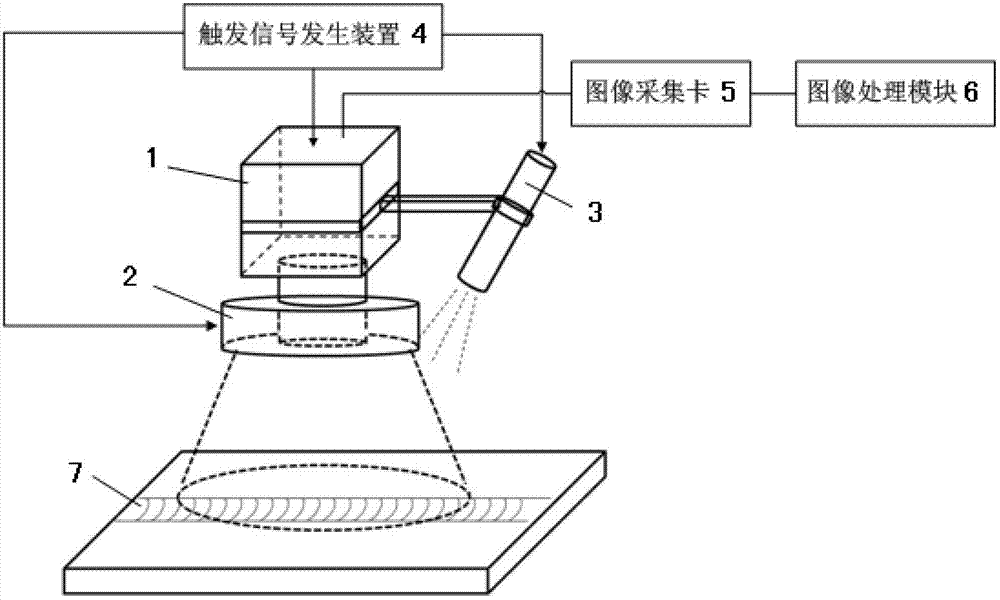

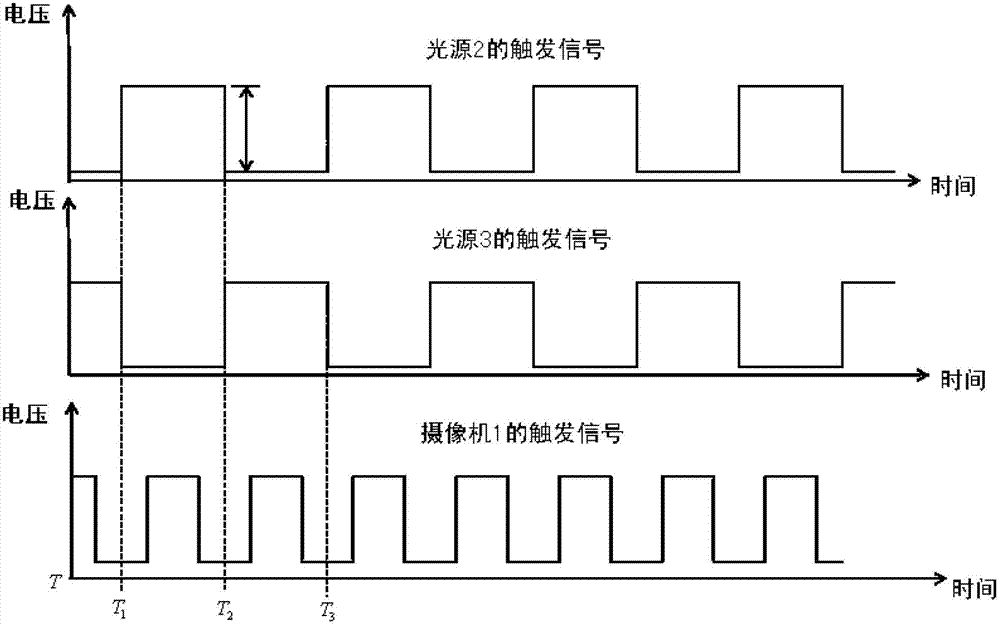

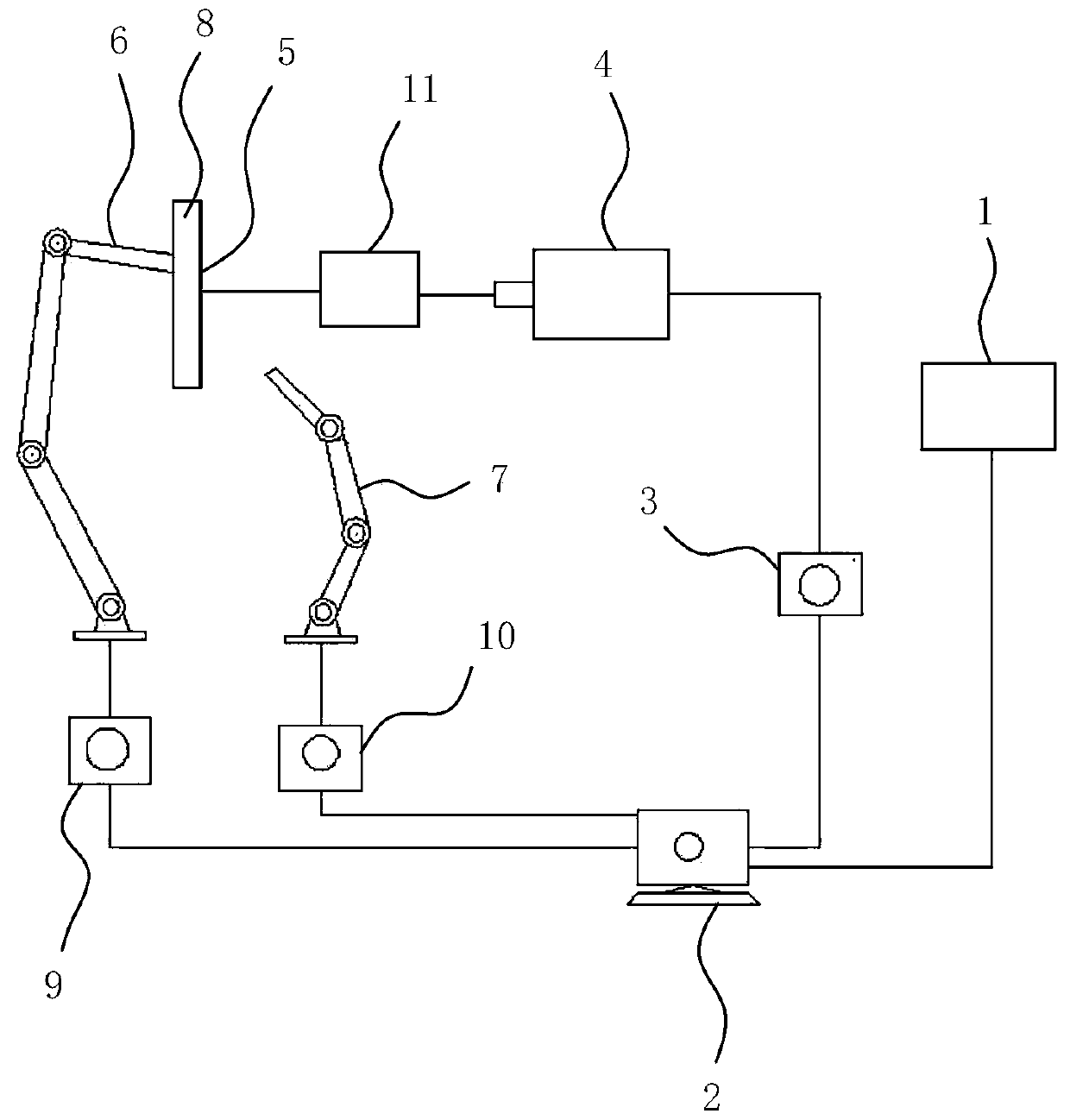

The invention relates to a light source alternate strobe synchronous camera shooting method and a vision detection system. The light source alternate strobe synchronous camera shooting method is characterized in that the vision detection system is arranged and comprises a camera, a spike filter, light sources, a trigger signal generating device, an image collecting card and an image processing module; the vision detection system is placed above an object to be detected; the trigger signal generating device simultaneously sends multi-way synchronous square signals to a camera shutter and each of the light sources to trigger the camera shutter and the light sources to work; during one trigger period of the synchronous square signals, the light sources are alternately lightened to irradiate the object to be detected, during the period that each of the light sources is lightened, the camera shoots an image of the light source irradiated object to be detected and sends the image to the image processing module through the image collecting card; and during different trigger periods of the synchronous square signals, the light sources are alternately lightened or extinguished in certain frequency periods, and the camera alternately shoots images of the object to be detected until all the images of the object to be detected are collected. The light source alternate strobe synchronous camera shooting method and the vision detection system can be widely applicable to processes that objects to be processed are subjected to image shooting during groove detection, rear-time welding seam tracking, welding seam molding quality detection and the like in robot automatic welding.

Owner:TSINGHUA UNIV

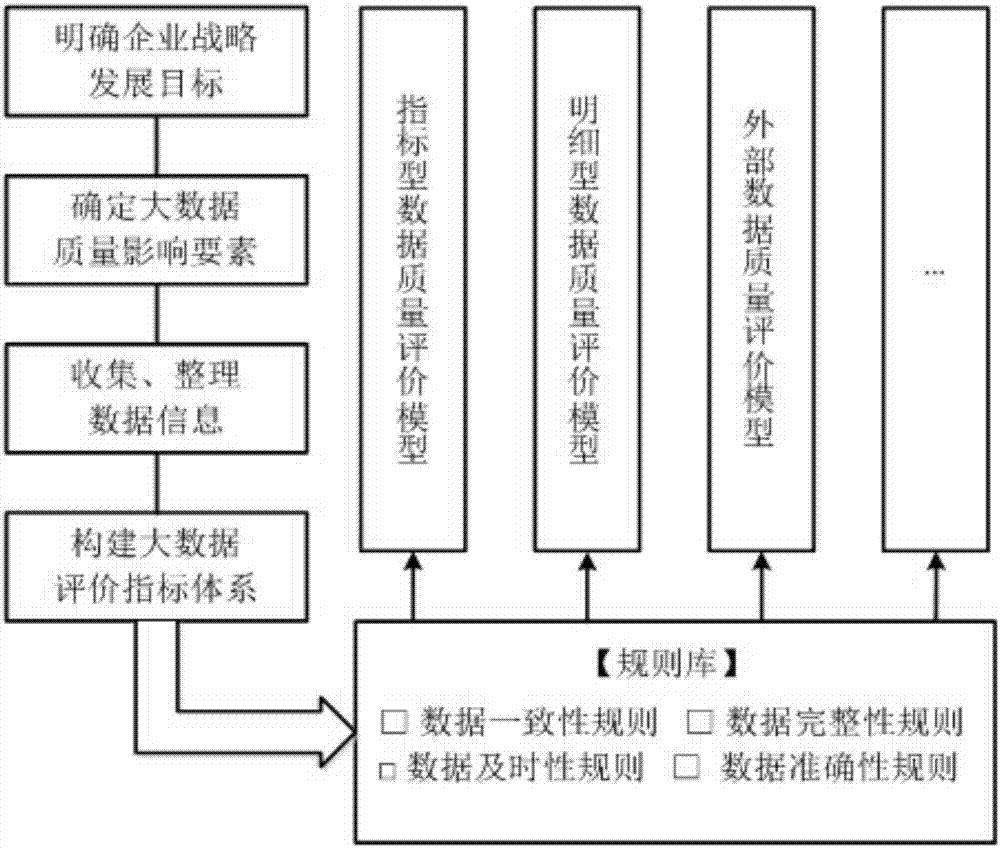

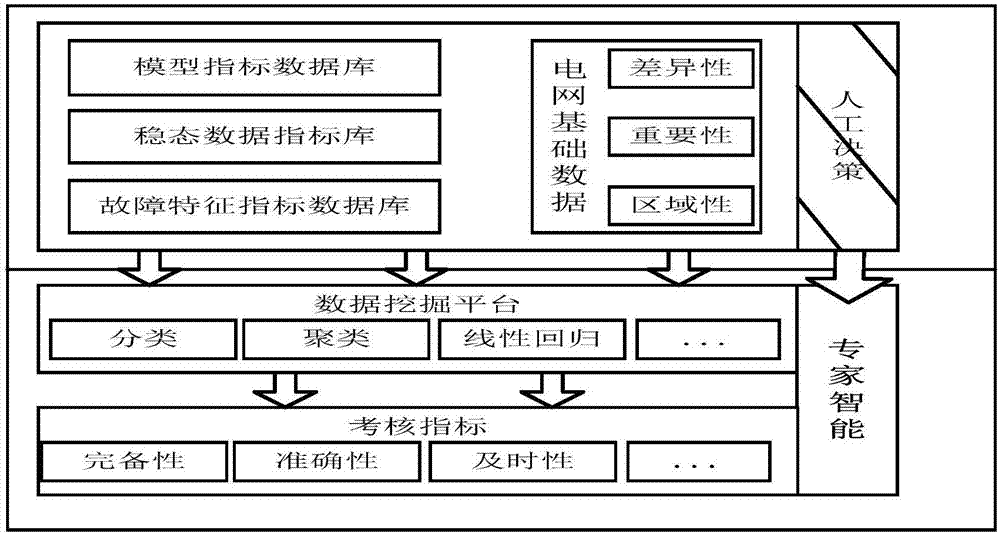

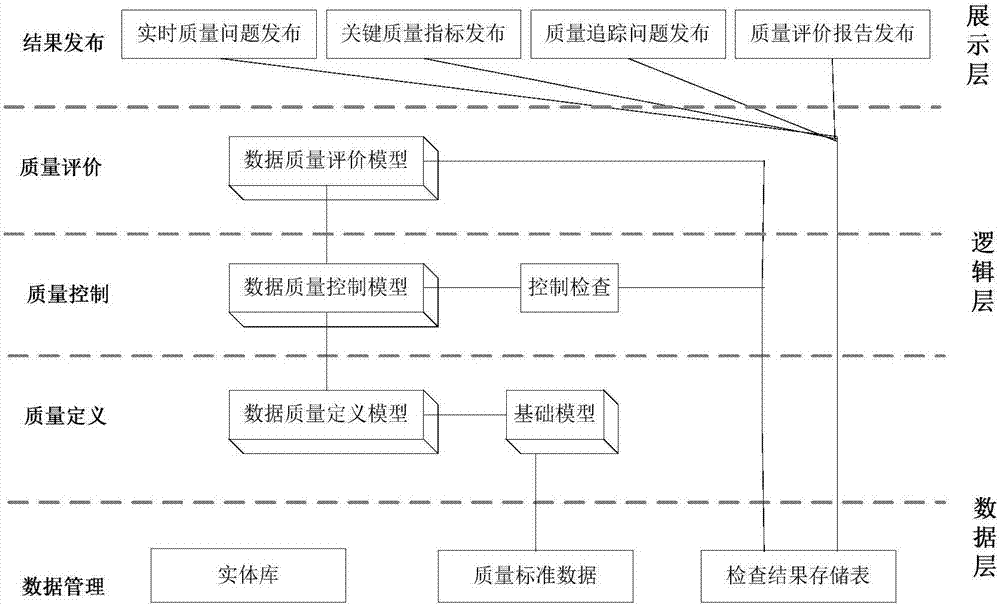

Data quality analysis evaluation model facing electric power big data

PendingCN107545349AIntegrity guaranteedEnsure consistencyResourcesData integrityIntelligent management

The invention discloses a data quality analysis evaluation model facing electric power big data. Core functions of the data quality analysis evaluation model facing electric power big data comprise steps of performing processing on a collection plan and a restriction rule in a basic model, calling a background storage realizing checking and analysis through a data quality control model, executingchecking and forming a checking result in an entity database, performing analysis, computing, classification and summarization through an analysis program, generating a quantized index result reflecting a plan completion state and data quality, storing the result in an analysis result table, and calling the analysis table through a foreground to generate a data quality analysis evaluation report which reflects various quantized indexes of data quality problems in detail. The invention improves an automated level of data quality analysis and evaluation, realizes intelligent management and control of data quality, satisfies data quality control requirement for big batch data, and realize quantized analysis and evaluation for data integrity, timeliness, accuracy and consistency.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

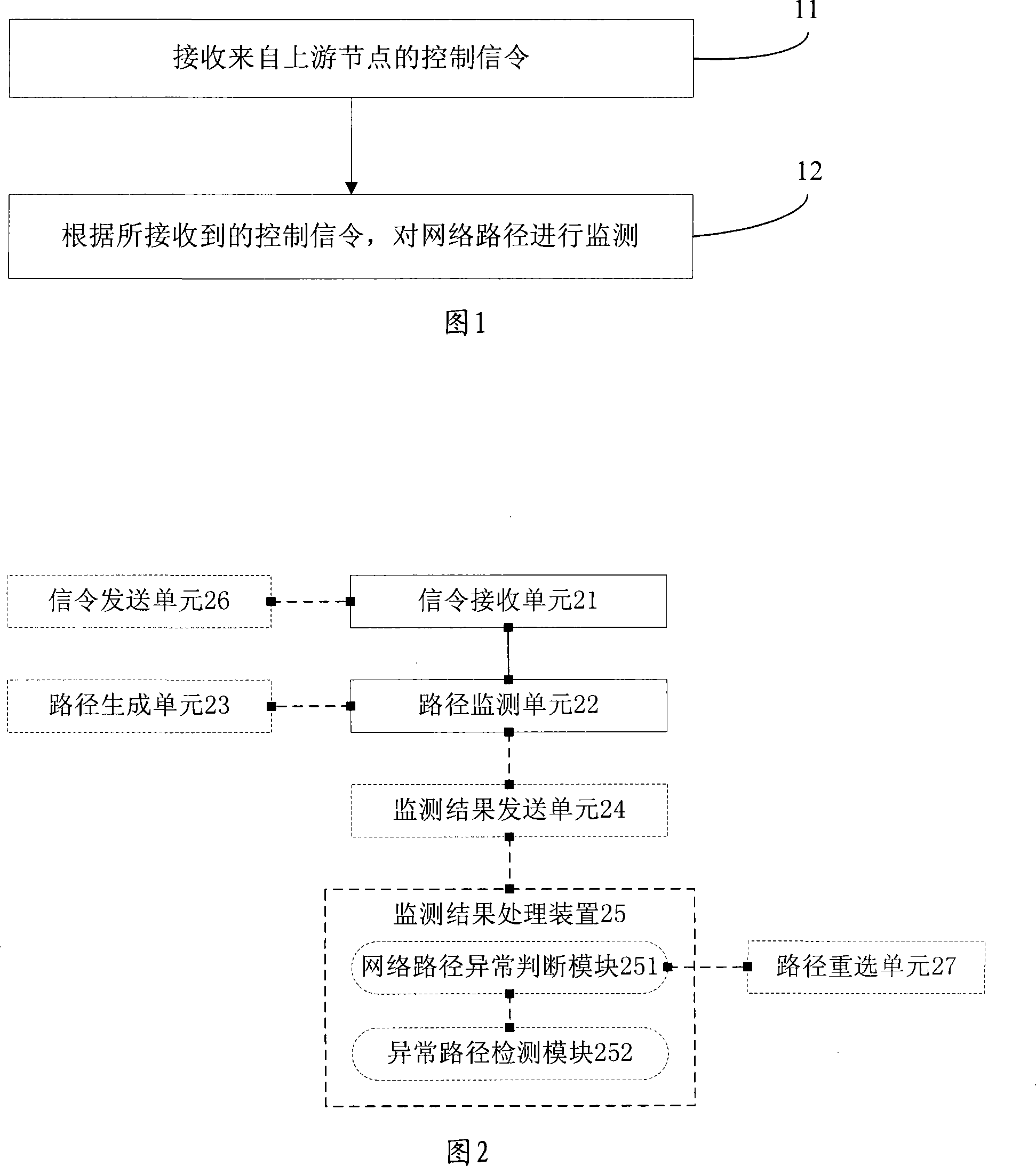

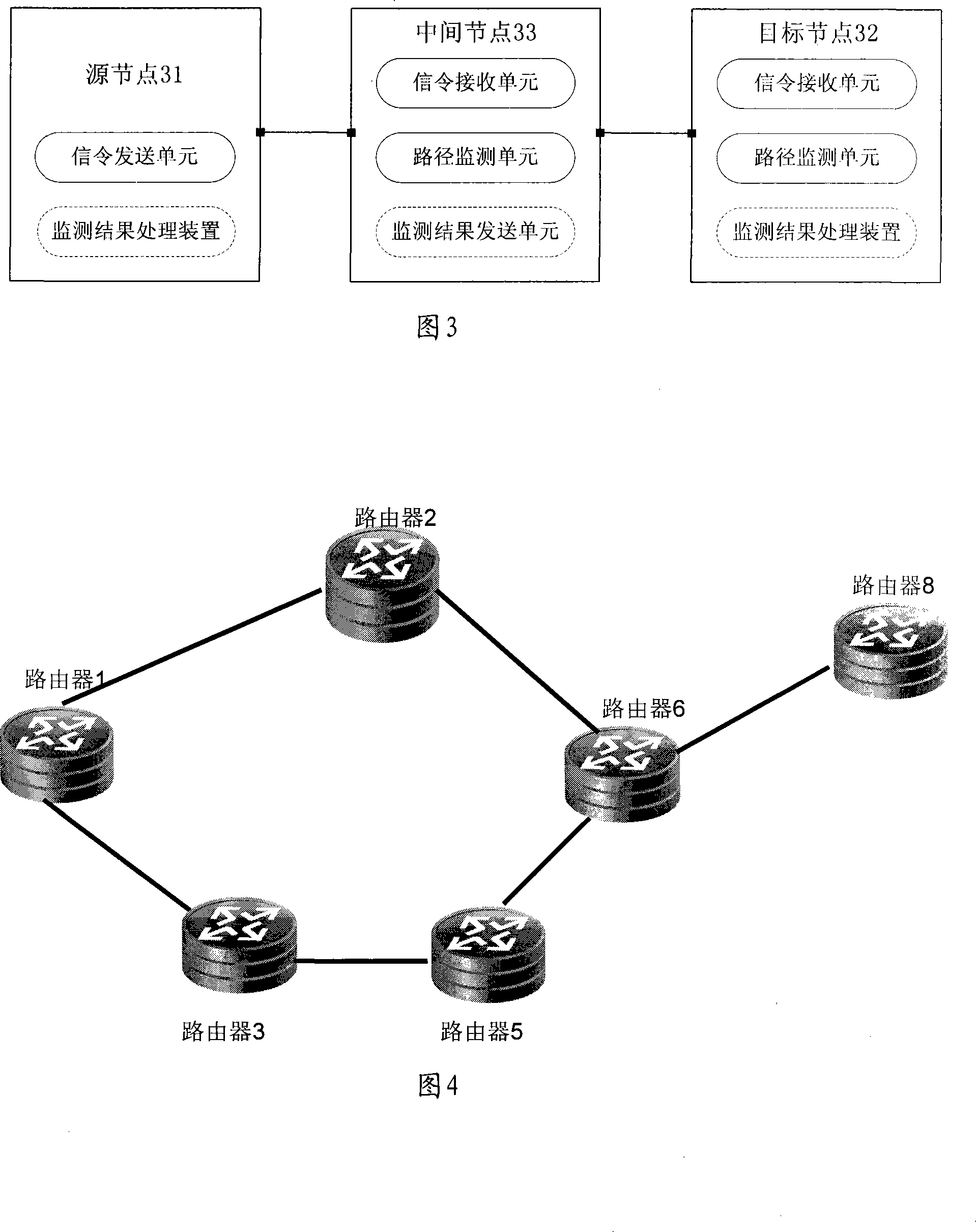

Method and device for monitoring network path

InactiveCN101242320AHigh monitoring granularityMeet the needs of quality controlData switching networksGranularityControl signal

An embodiment of the invention provides a method and a device for monitoring network path, comprising: firstly, receiving a control signaling from an upper node; and then monitoring the network path based on the received control signaling. Each node on the way in the network path can take part into the monitor of network path by using the signaling mechanism, such as, the nodes on the way acquire, adjust and analyze the NQA test data by controlling the signaling, and the monitor result process device can also rapidly and correctly judge which node occurs abnormity on the way of the network path by the feedback monitor result of the nodes on the way, realizes an all path nodes monitor and analysis on the network path, makes the monitor granularity of the network quality higher, and satisfies the require of network quality monitor.

Owner:HUAWEI TECH CO LTD

Detection and evaluation method for abradability of seal coating

InactiveCN108120650AMeet the needs of quality controlImprove quality controlInvestigating abrasion/wear resistanceInvestigating machinabilityThermal sprayingEngineering

The invention especially relates to a detection and evaluation method for the abradability of a seal coating, belonging to the technical field of aeroengines. The detection and evaluation method is applicable to determination of the abradability of thermally-sprayed abradable seal coatings. The method comprises the following steps: preparation of a coating; measurement and weighing; installation of blade samples; calibration of zero position; setting of test parameters; abrasion testing; and result analysis and evaluation. The detection and evaluation method provided by the invention is employed for studying the frictional wearing behaviors of three low-and-medium-temperature seal coatings, i.e., an AHB (aluminum / boron nitride) coating, a Metco601 (aluminum-silicon polybenzoate) and a Metco 307 (nickel graphite) coating, and matching pairs; and criteria are formulated for determination of the abradability of abradable seal coatings, including three qualitative criteria and four quantitative criteria, wherein the three qualitative criteria are composed of abrading force, the morphology and composition of the surfaces of abrasion scratches, and the morphology and composition of the cross sections of the abrasion scratches, and the four quantitative criteria are composed of a blade height abrasion ratio, a blade coating mass wear ratio, an abrasion scratch length ratio and an adhesion ratio.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

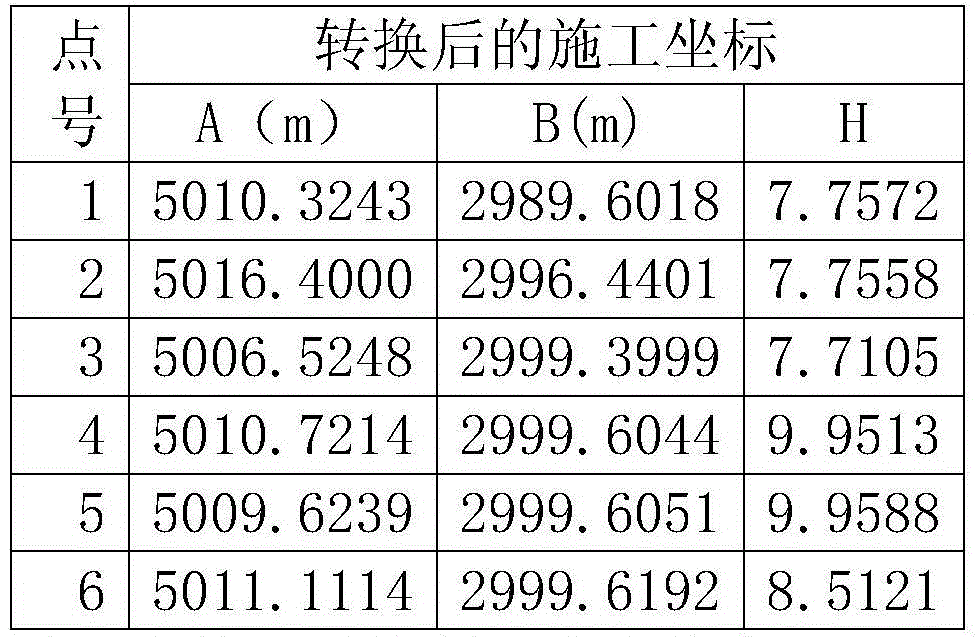

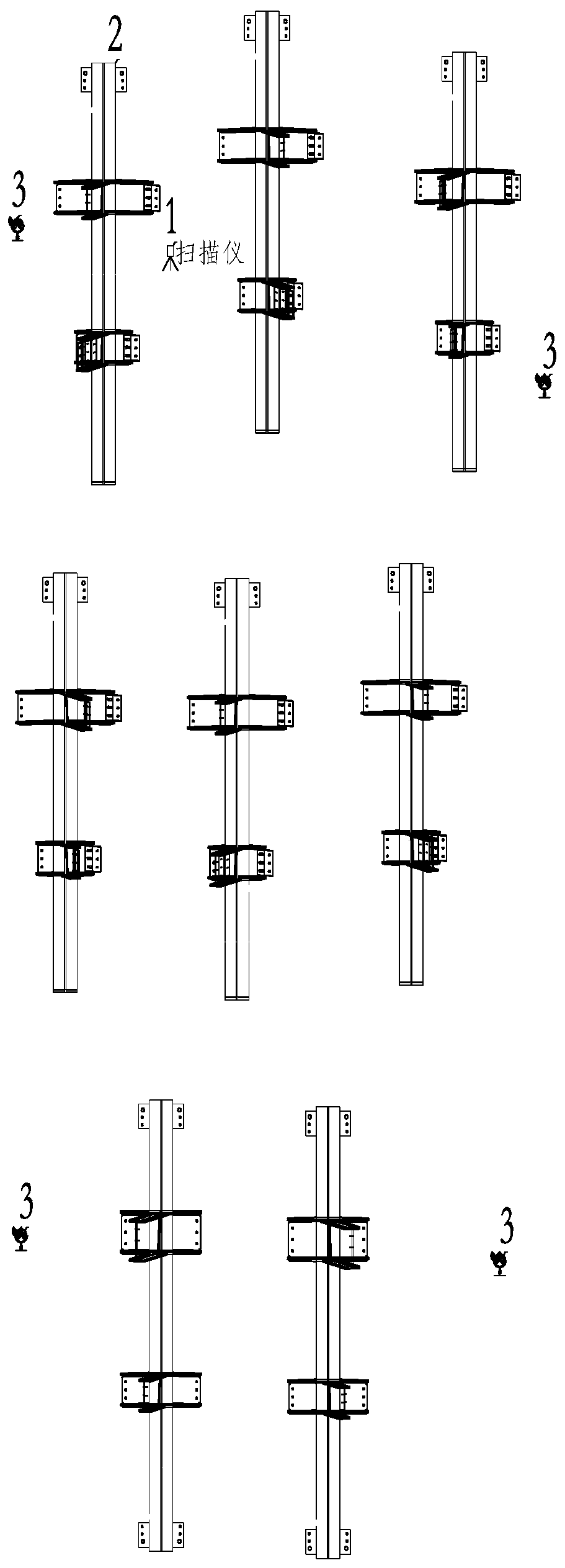

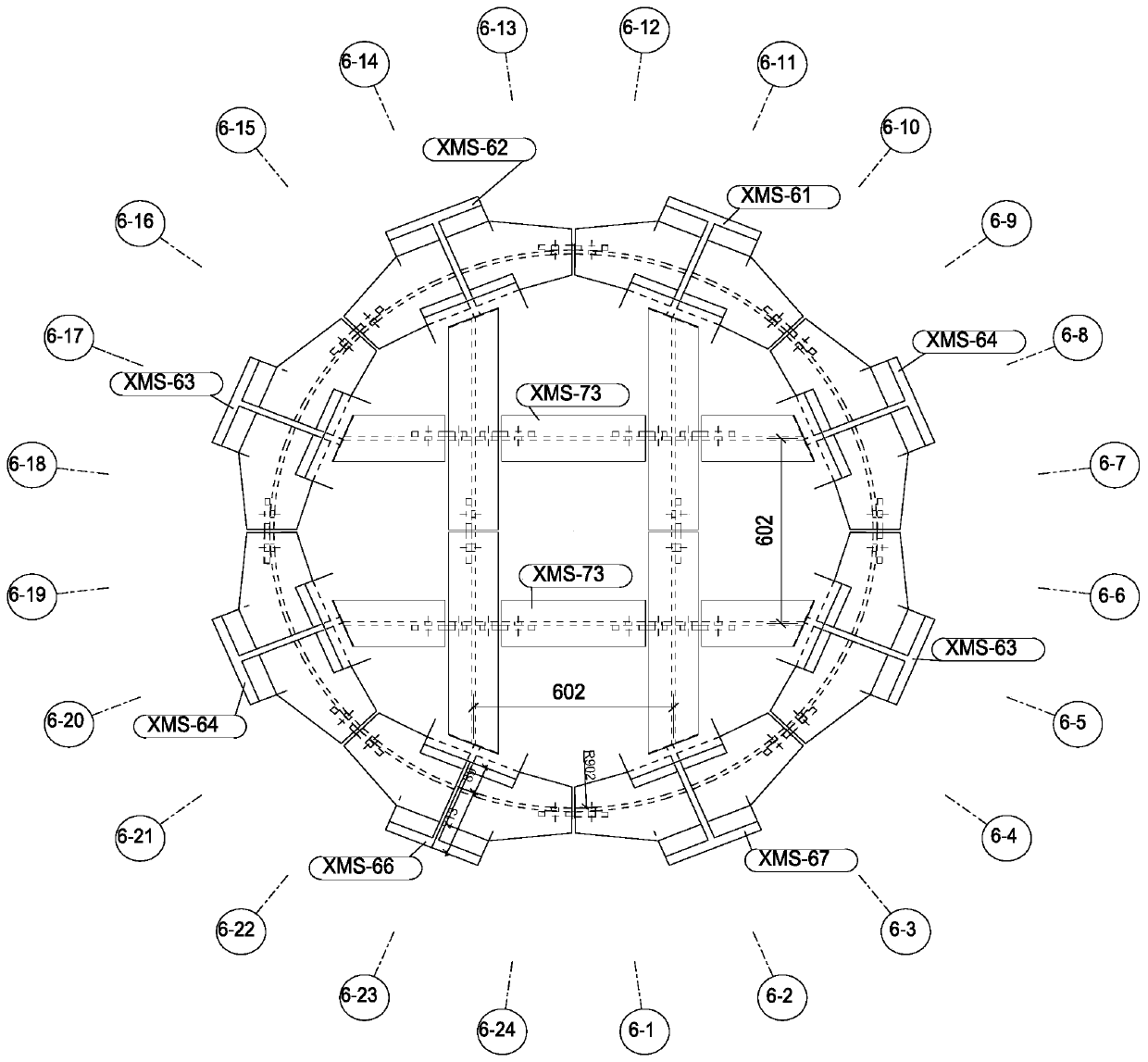

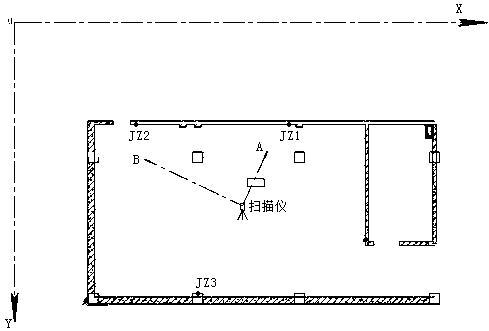

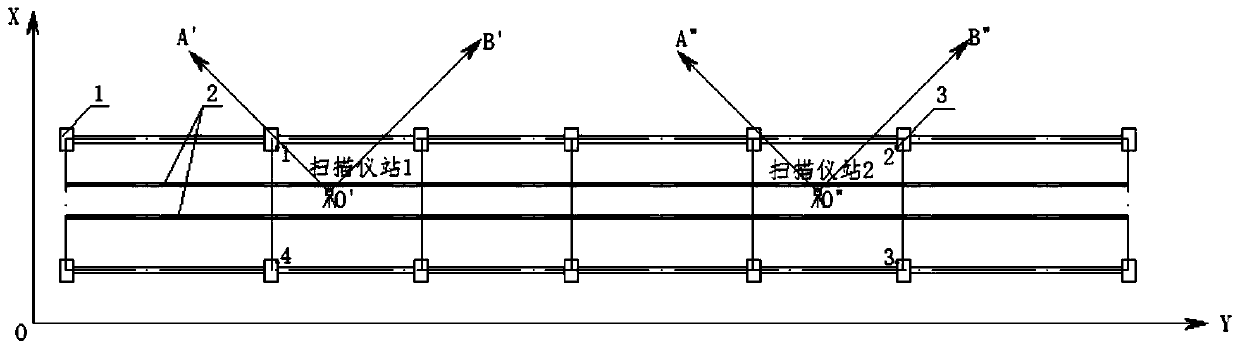

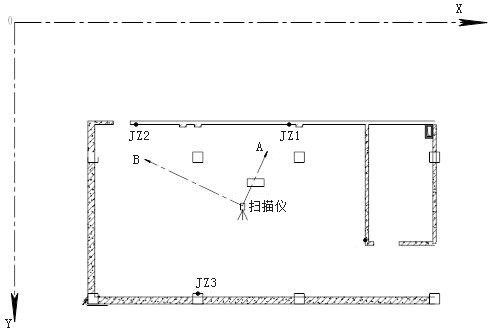

Three-dimensional scanner technology-based embedded part position detection method

ActiveCN105823414ASolve inspection problemsImprove securityUsing optical meansNuclear powerQuality control

The invention relates to a three-dimensional scanner technology-based embedded part position detection method. The method comprises steps: all embedded part central points are marked, three or more than three control reference points are selected from the embedded part central points, coordinates of the control reference points in a construction coordinate system are measured, a scanner is erected, positions with the embedded part central points are scanned, data of the scanner are read, numbers of the embedded part central points are marked according to the scanned data, a file is used for outputting coordinates of each point of the embedded part central points, the scanned data are converted into the construction coordinate system through the control reference points, and coordinate values of the embedded part central points in the construction coordinate system are obtained. According to the method of the invention, an accurate detection result can be obtained, a basis can be provided for detection and acceptance of a nuclear power construction wall and a bottom plate embedded part, the difficult problem of detecting positions of embedded parts, especially when the number of embedded parts is large, in the case of nuclear power construction can be solved, safety of detecting an overhead embedded part is improved, the detection is flexible, and field construction quality control requirements can be met.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

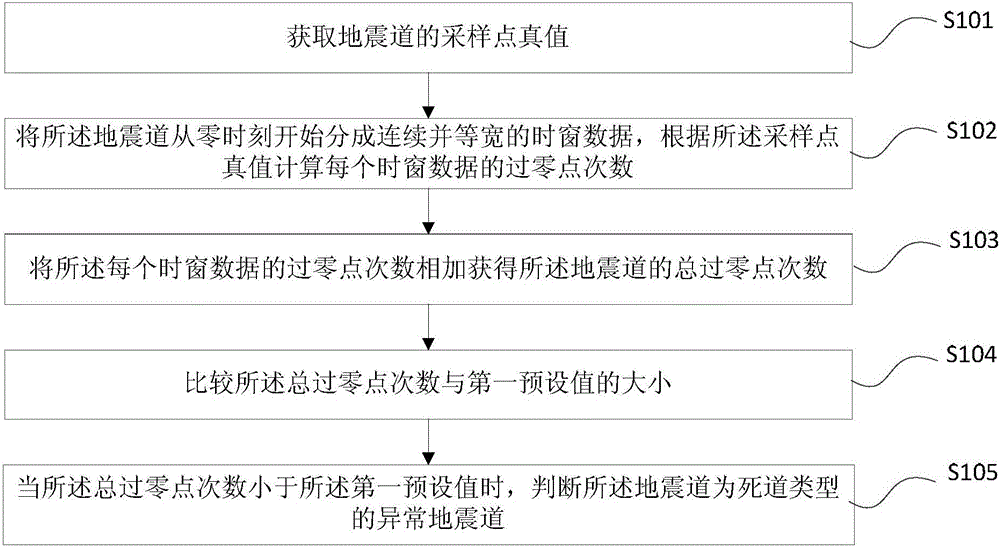

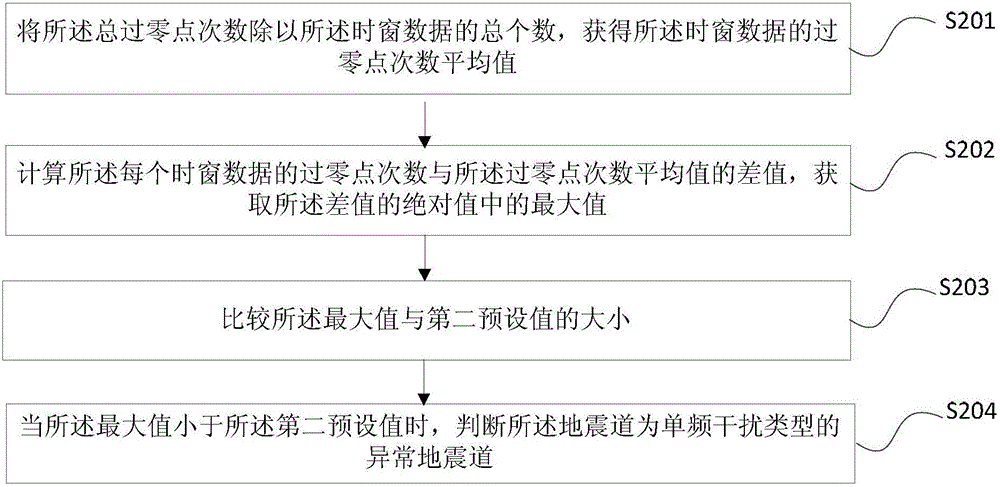

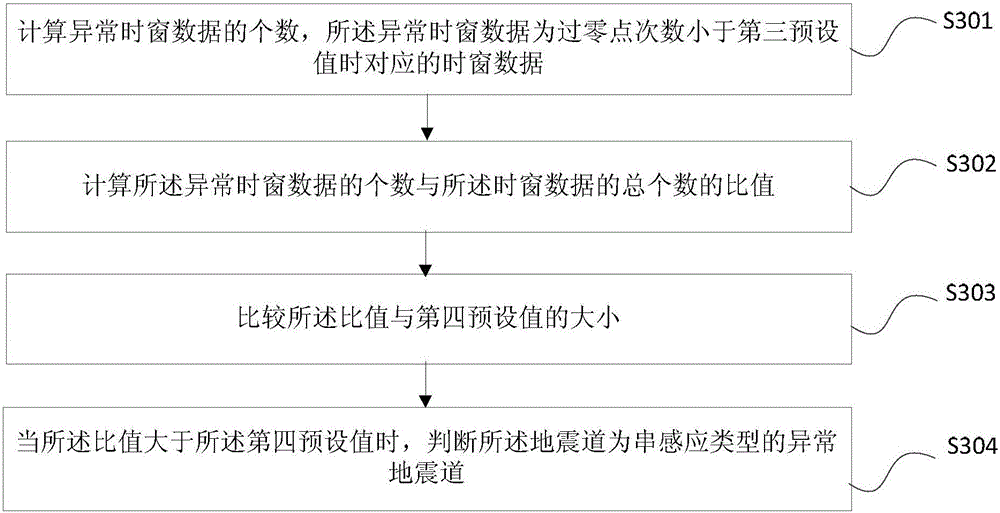

Abnormal seismic trace automatic discriminating method and device

ActiveCN105785437ARealize automatic discriminationMeet the needs of quality controlSeismic signal processingTruth valueSeismic trace

The present invention relates to the seismic data quality monitoring field, in particular to an abnormal seismic trace automatic discriminating method and device. The method comprises the steps of obtaining the sampling point truth-value of a seismic trace; dividing the seismic trace into the time window data which is continuous and has the equal width from the zero hour, and according to the sampling point truth value, calculating the zero-crossing times of each time window data; summing the zero-crossing times of each time window data to obtain the total zero-crossing times of the seismic trace; comparing the total zero-crossing times with a first preset value; when the total zero-crossing times is less than the first preset value, determining that the seismic trace is an abnormal seismic trace of a dead trace type. According to the embodiment of the present invention, according to the total zero-crossing times characteristic of the abnormal seismic trace of the dead trace type, by just gathering and comparing the zero-crossing times simply during the discrimination process, and being compared with the prior art, the method of the embodiment of the present invention is simple, is high in operation efficiency, and satisfies the demand of the mass seismic data quality control.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Improved casting process of high-carbon steel in production of billet continuous casting

InactiveCN107570675ALittle segregationImprove the level of technologyMelt-holding vesselsSlagCarbon steel

The invention discloses an improved casting process of high-carbon steel in the production of billet continuous casting. The casting process comprises the following steps that (1), the installation ofa long nozzle is improved, the installation quality of the long nozzle is improved, and the deviation of the long nozzle is avoided; (2) a tundish and long nozzle argon blowing device is adopted to guarantee that molten steel in the tundish is slightly overturned in the argon blowing process, and the phenomenon that the molten steel is splashed is not allowed; (3) a slag blocking wall is adoptedin the tundish; (4) the tapping temperature is controlled at 1595+ / -10 DEG C; (5) reasonable ladle operation is adopted, and the temperature is lowered at the speed of lower than or equal to 3 DEG C per minute; and (6) the use of a tundish covering agent is enhanced, wherein the covering agent is a carbon-free magnesium oxide covering agent, and the adding amount is 0.6kg per ton of molten steel.According to the improved casting process, the removal of inclusions is facilitated, the control over the superheat degree of the molten steel is enhanced, the use of the tundish covering agent is enhanced, the surface quality and the internal quality of the continuous casting blank are improved, and the market competitiveness of the product is improved.

Owner:XINJIANG BAYI IRON & STEEL

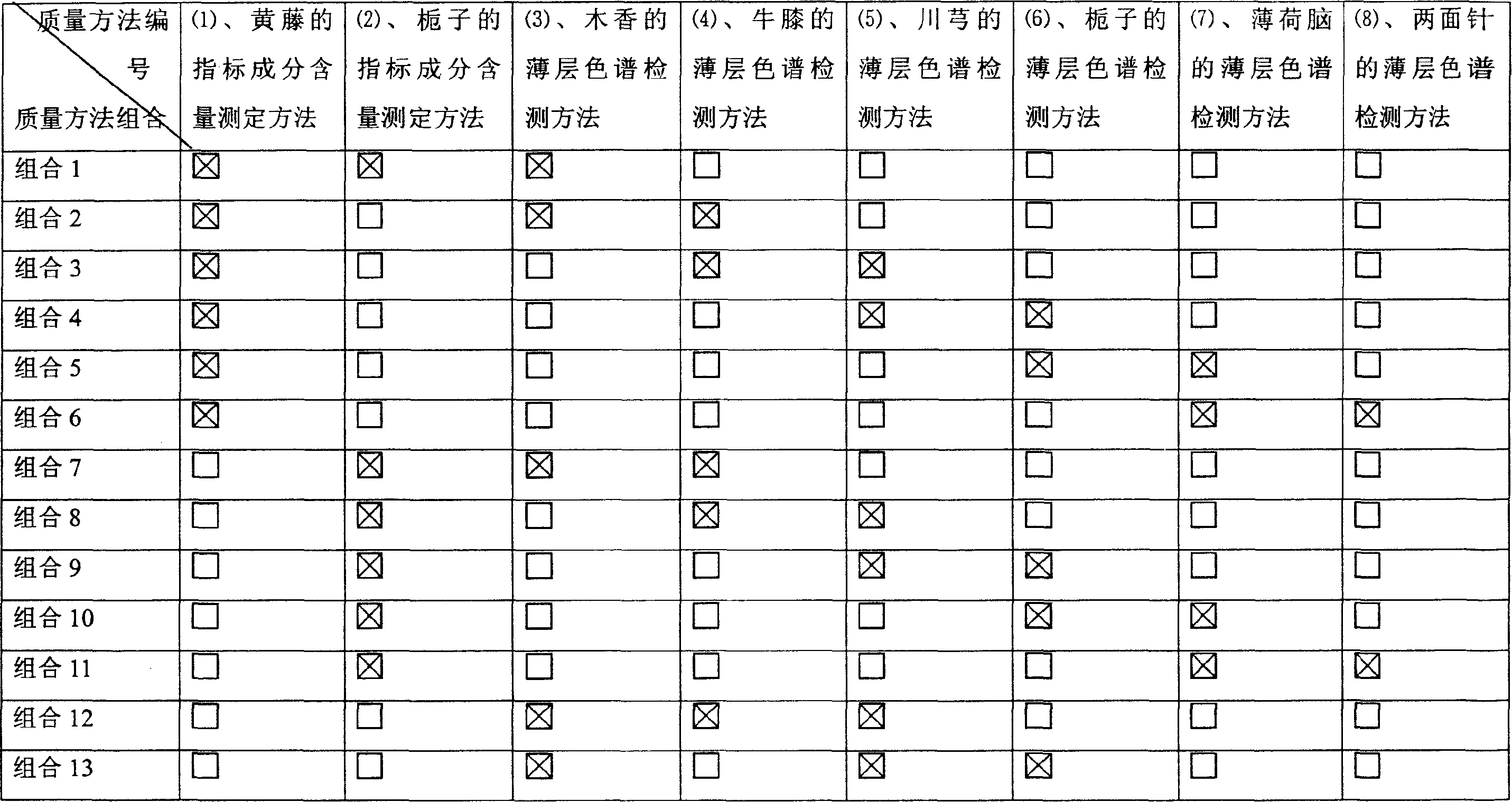

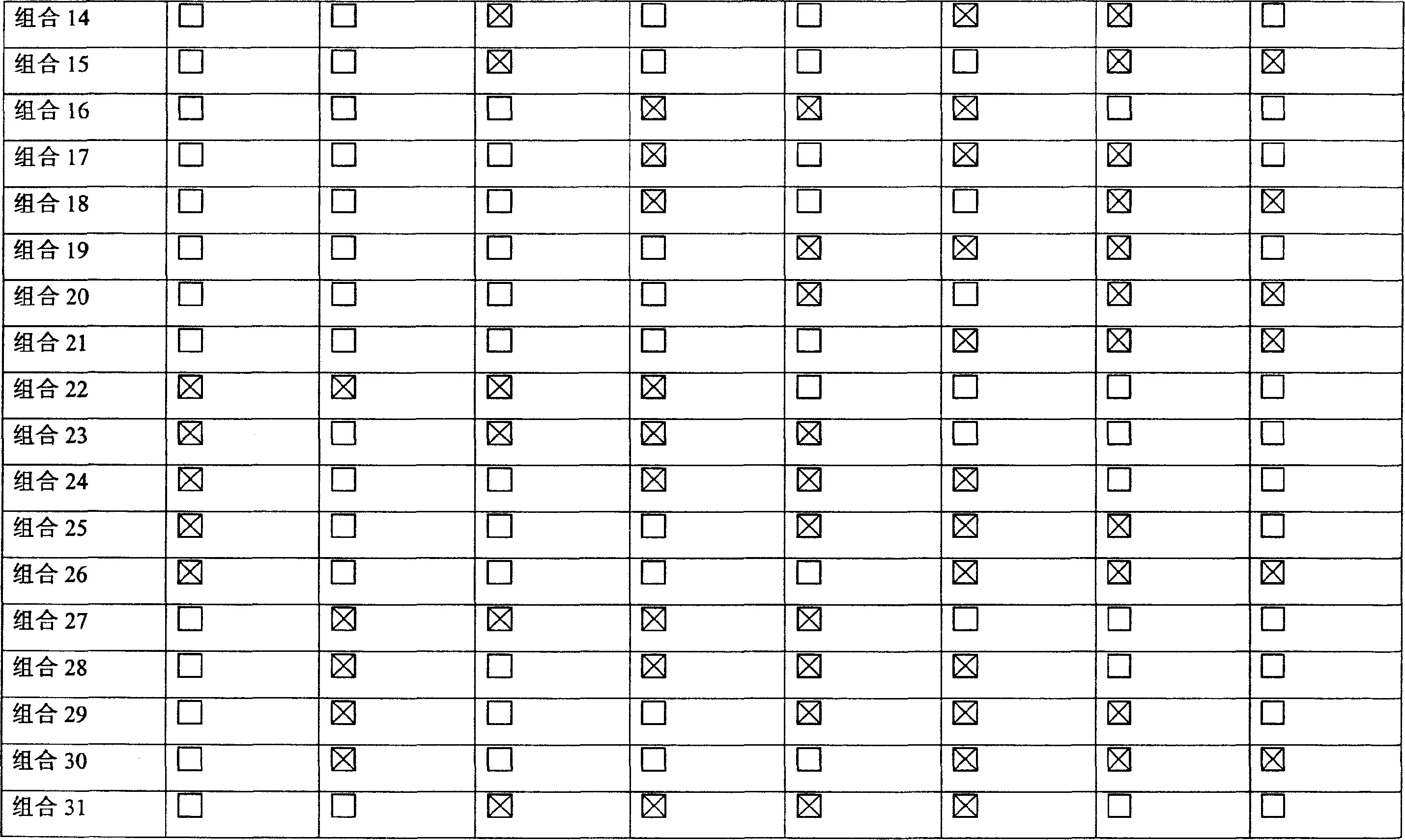

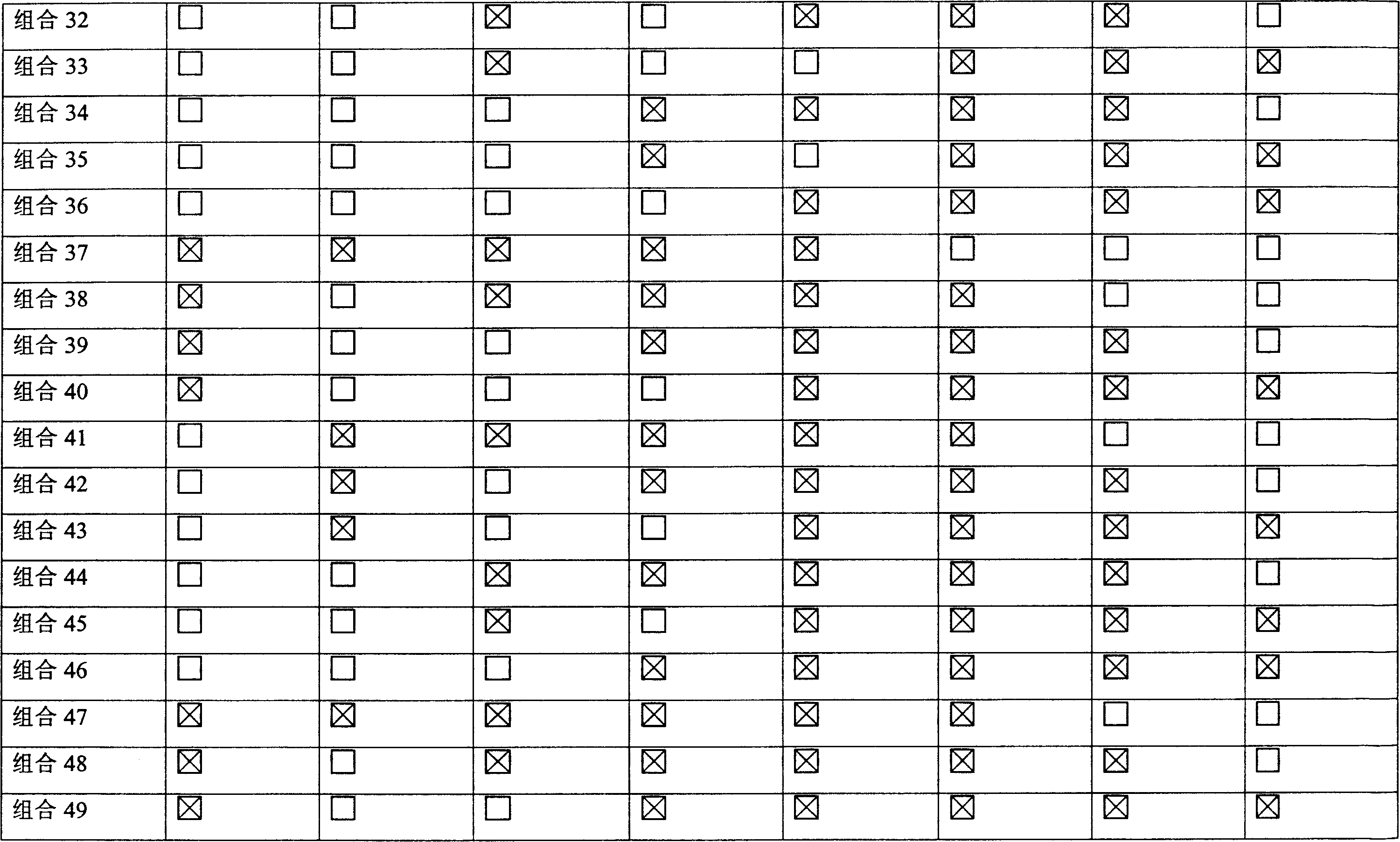

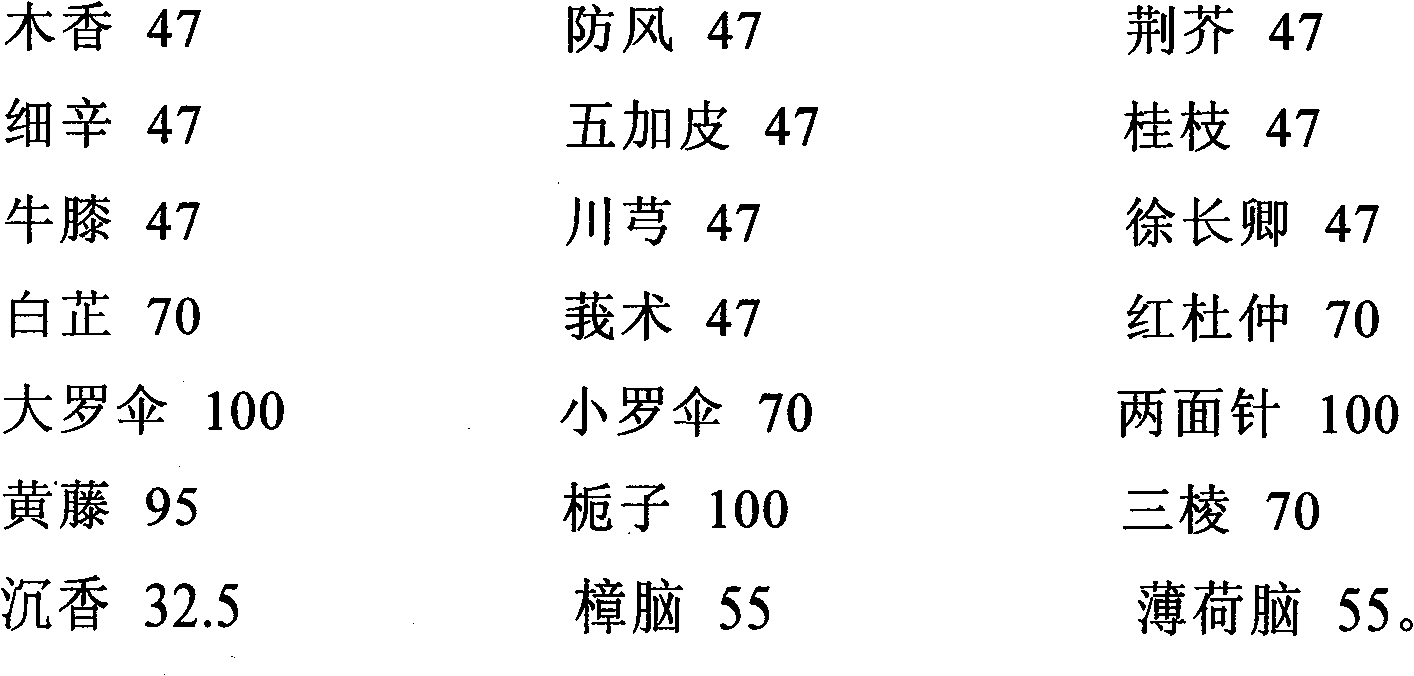

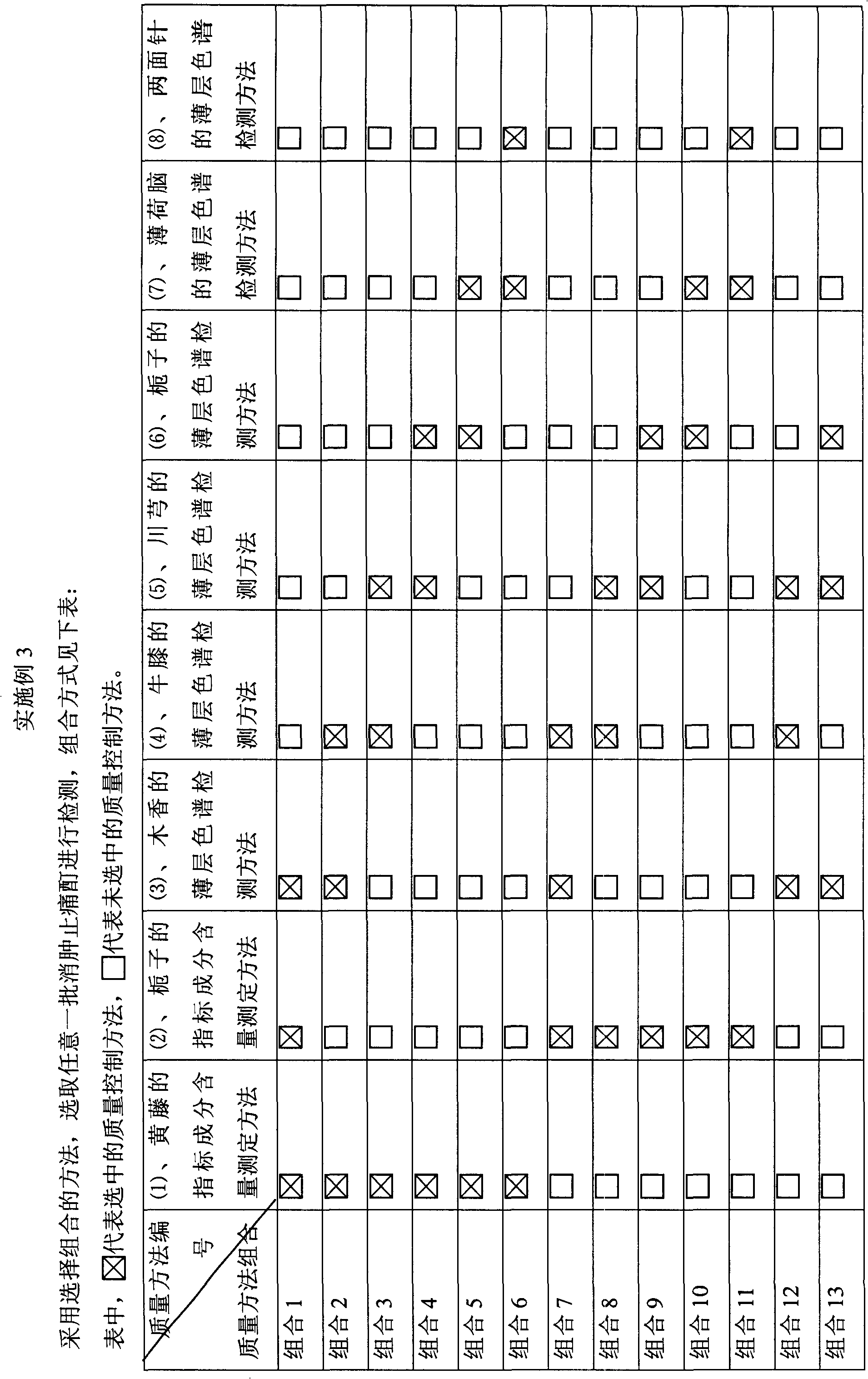

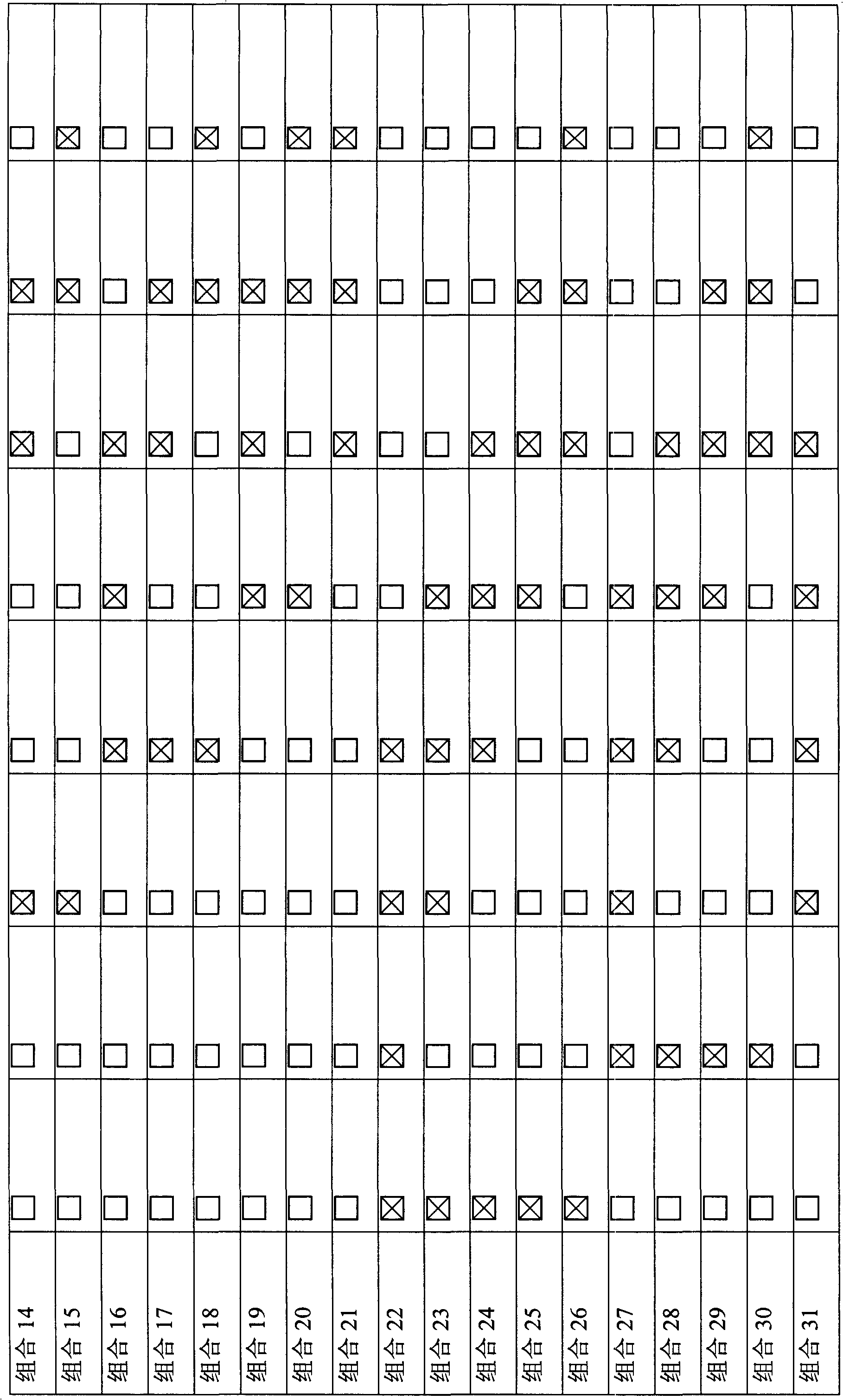

Quality control method of traditional chinese medicine preparation for treating traumatic injury and rheumatism ostealgia

ActiveCN101138594AMeet the needs of quality controlEasy qualityComponent separationAntipyreticInjury causeRheumatism

The present invention discloses a quality control method of Chinese medicine for treating traumatic injuries and rheumatic pain. The present invention combines the index component content mensuration and the thin-layer chromatography detection method for Chinese medicine, so as to achieve the aim of controlling and evaluating the quality of the Chinese medicine. Compared with the traditional quality control method, the method provided by the present invention is more scientific, reasonable and effective. In terms of operation, the method provided by the present invention has the advantages of simple operation, accuracy and reliability, high precision and high practical value.

Owner:广西壮族自治区花红药业集团股份公司

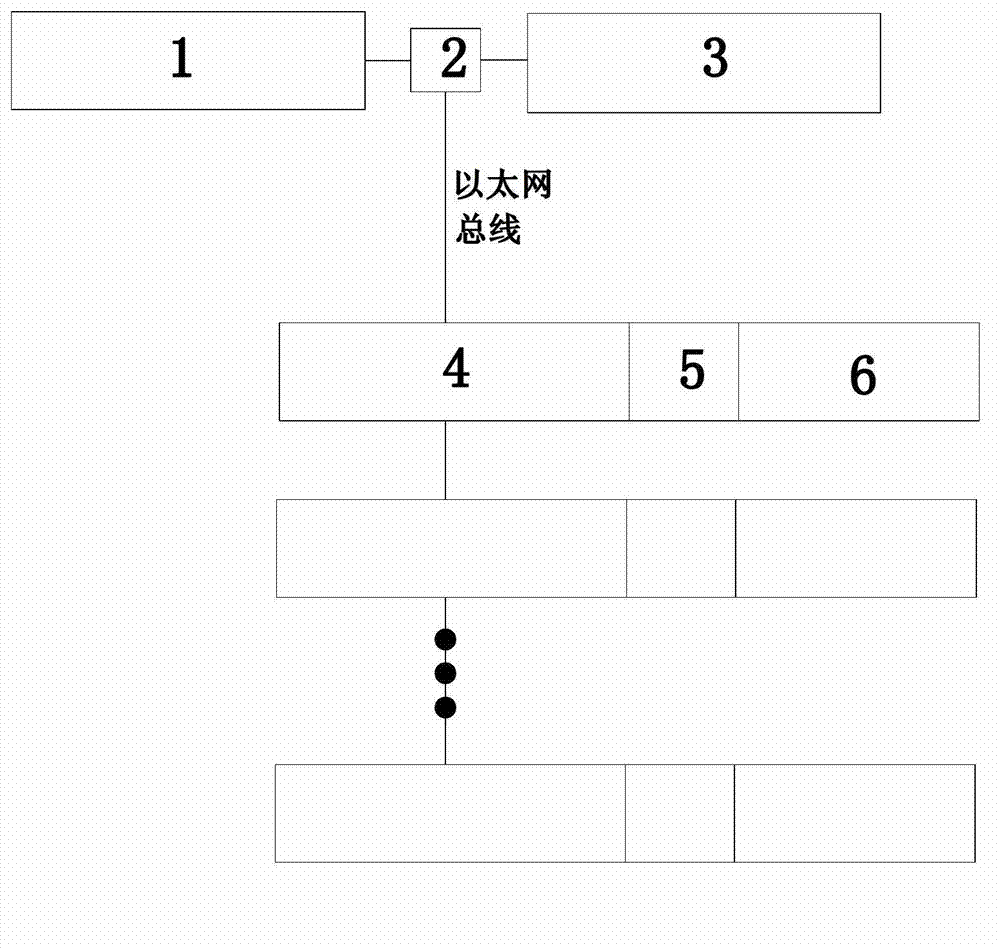

Method and device for detecting and controlling quality of rigid production line in Ethernet bus mode

InactiveCN102968106AMeet quality control needsSimple structureTotal factory controlProgramme total factory controlProduction lineControl quality

The invention discloses a method and device for detecting and controlling quality of a rigid production line in an Ethernet bus mode. The method comprises the following steps that: each corresponding station is machined through a plurality of machining devices, and station information is acquired through a controller; the acquired station information is transmitted to a main control computer by an Ethernet conversion module through a remote access module; the main control computer proposes product quality trend state information according to the acquired station information through a quality analysis module; and the machining devices are fed back through the controller according to the product quality trend state information. The method and the device can be used for controlling the quality of the station of the rigid production line, so that the product quality is improved, and the production cost is reduced.

Owner:WENZHOU UNIVERSITY

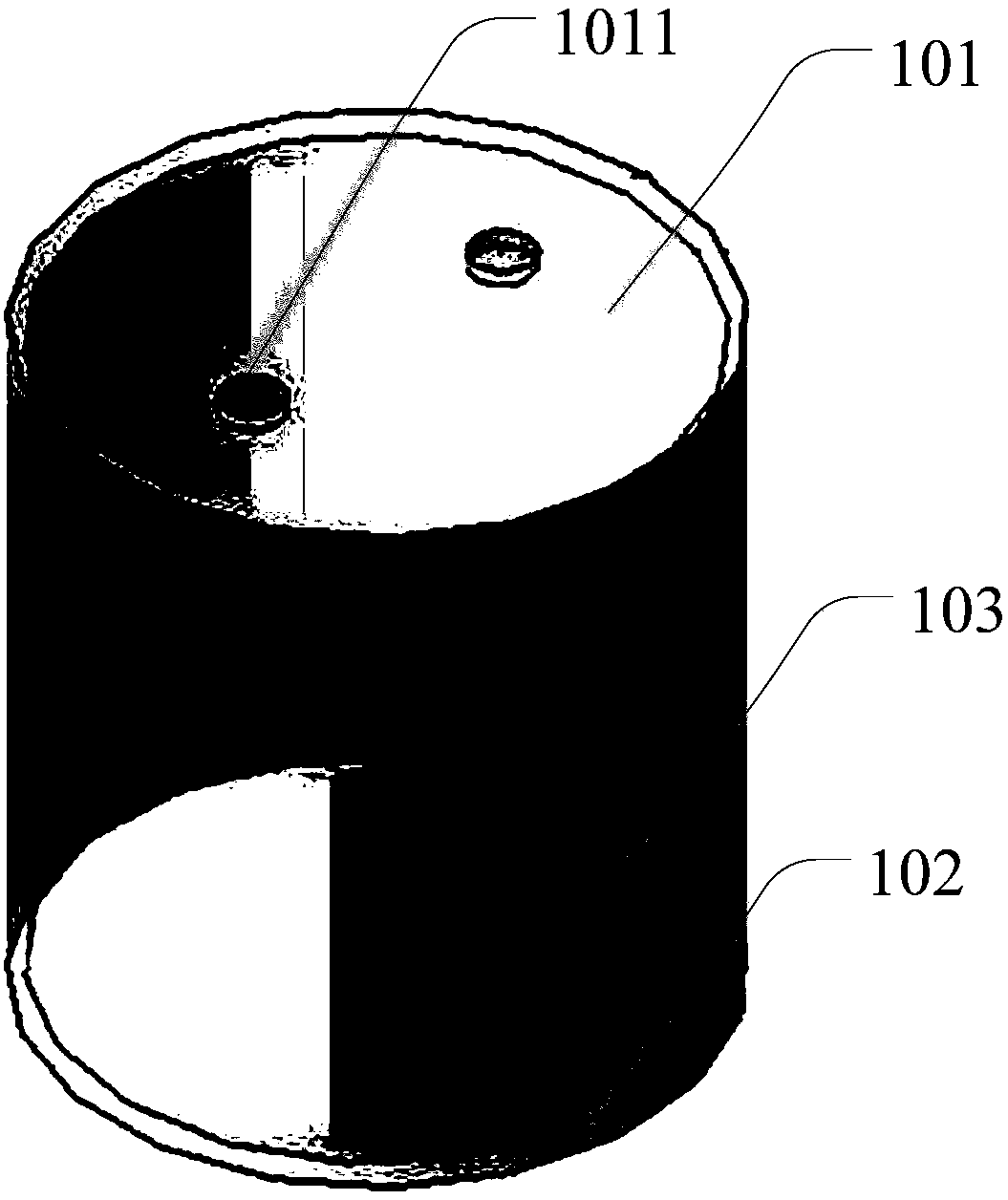

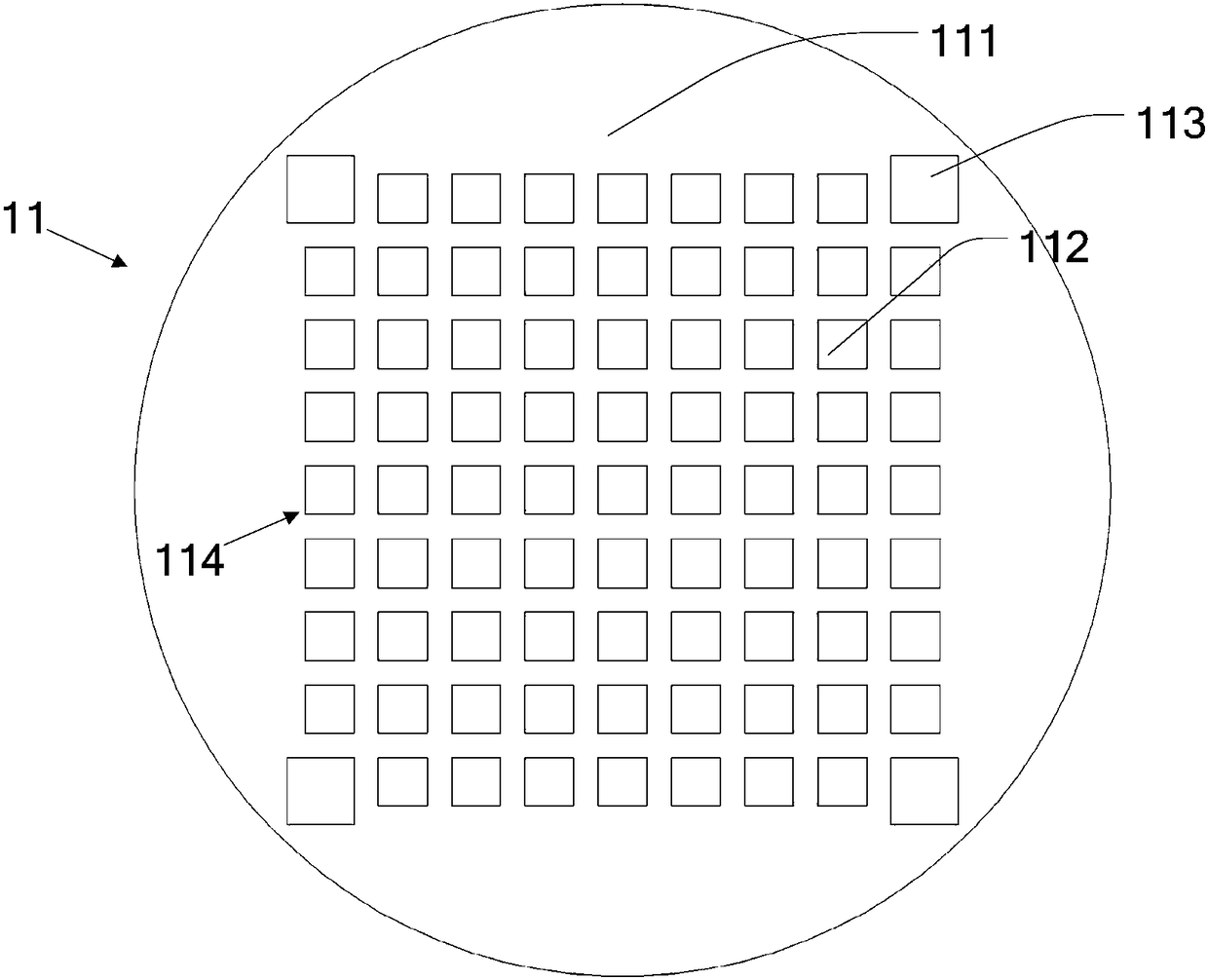

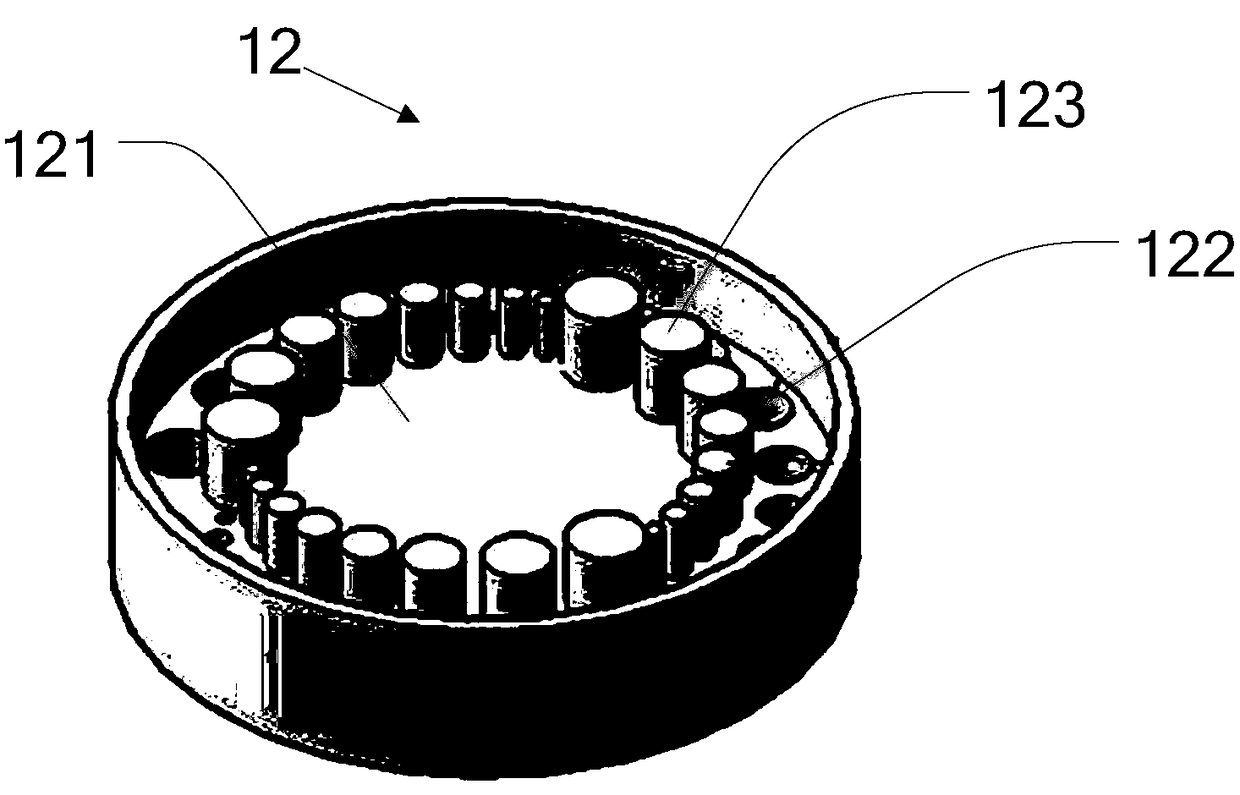

Quality-control multi-parameter model for magnetic resonance imaging system and CT equipment

InactiveCN108567428AMeet the needs of quality controlFlexible combinationDiagnostic recording/measuringSensorsQuality controlEngineering

The invention provides a quality-control multi-parameter model for a magnetic resonance imaging system and CT equipment. The quality-control multi-parameter model comprises a box body and multiple test blocks; the test blocks comprise test layers and supporting layers for stacking and positioning the test blocks, the multiple supporting layers are sequentially stacked and arranged in the box body,and the test layers are arranged in the supporting layers; the multiple test layers comprise image geometric distortion test layers, low-contrast-resolution test layers and uniformity and signal-to-noise-ratio test layers, or the multiple test layers comprise any two of image geometric distortion test layers, low-contrast-resolution test layers and uniformity and signal-to-noise-ratio test layers. The quality-control requirement of the MRI and the quality-control requirement of the CT equipment can be simultaneously met, the product function is diverse, different test requirements can be met,multiple parameters can be simultaneously measured, the accuracy and modularization are high, and the test layers can be flexibly combined.

Owner:ANHUI PROVINCIAL HOSPITAL

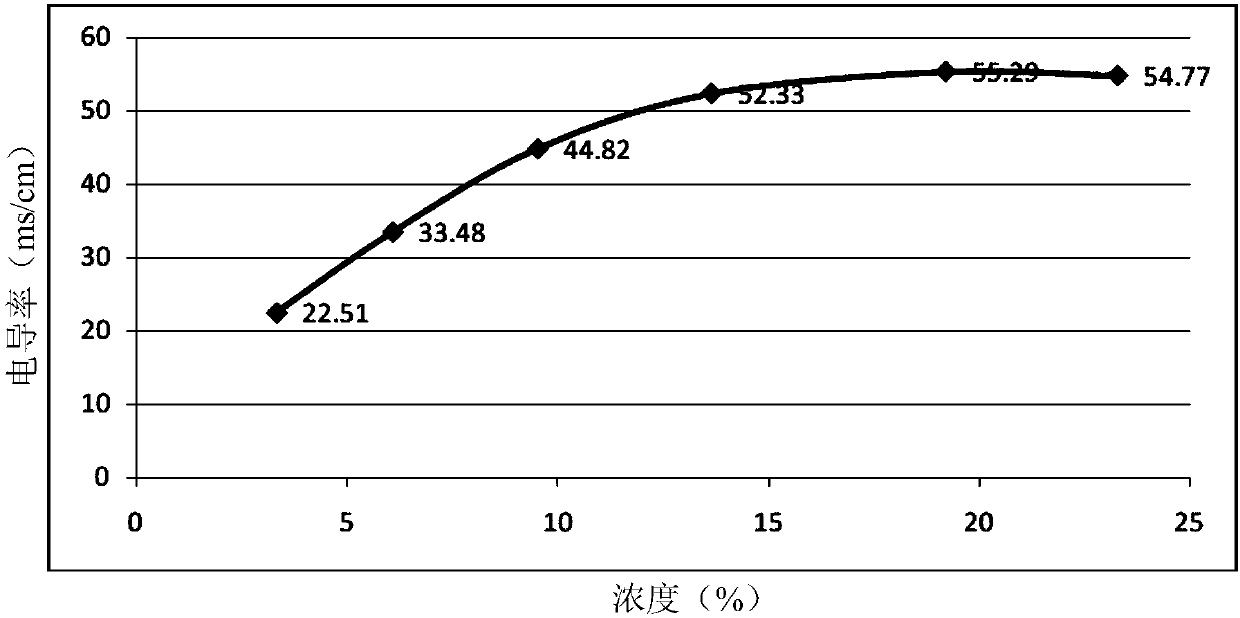

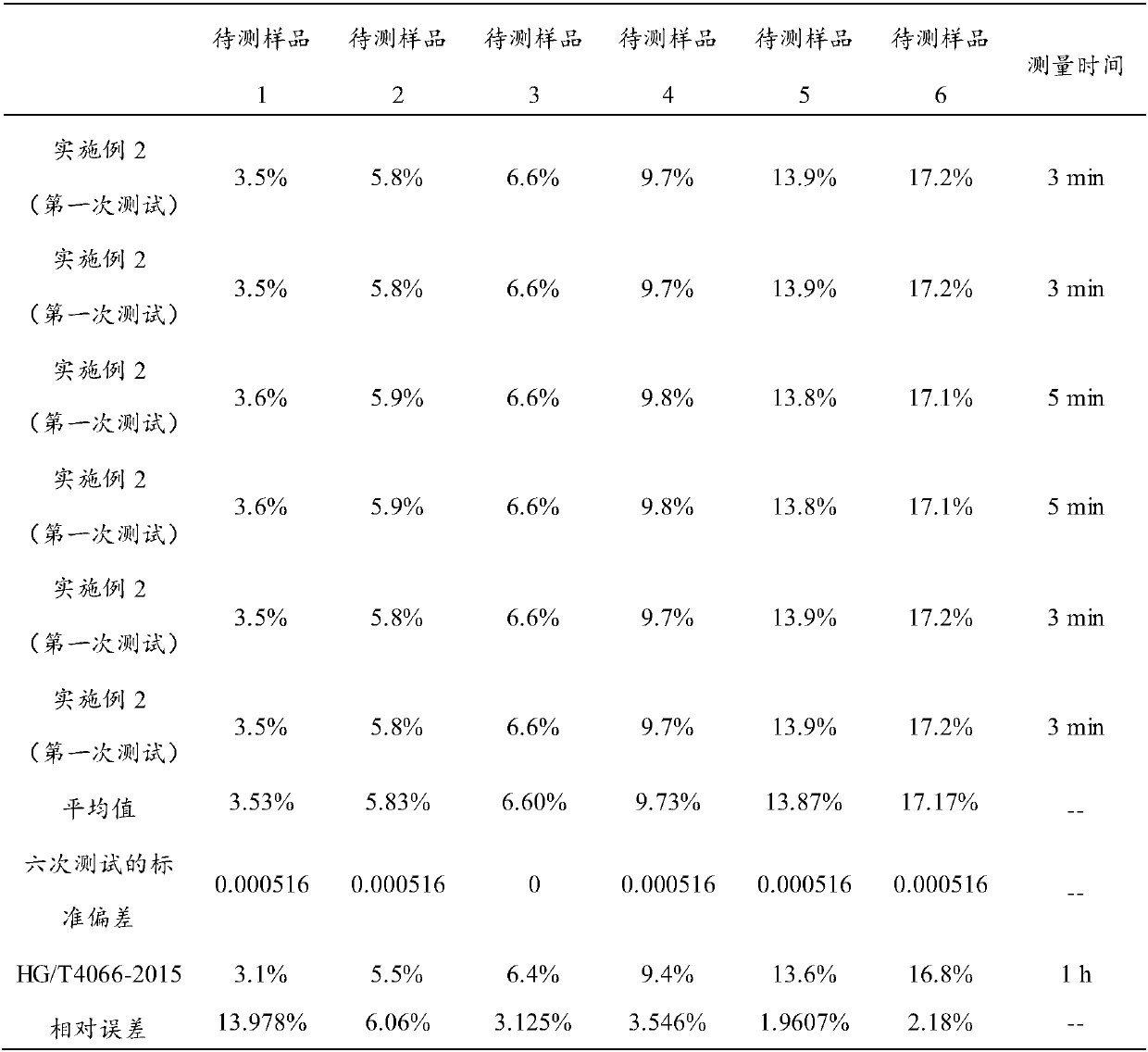

Inorganic electrolyte lithium salt content detection method

InactiveCN107807150AConcentration rapid detectionGood repeatabilityMaterial resistanceLithiumOrganic solvent

The invention provides an inorganic electrolyte lithium salt content detection method. The method comprises the following steps: a to-be-measured sample solution containing inorganic electrolyte lithium salt is subjected to constant-temperature standing, conductivity is tested, and according to a conductivity curve of an inorganic electrolyte lithium salt standard solution, the content of the inorganic electrolyte lithium salt in the to-be-measured sample solution can be obtained. Compared with the prior art, by using different concentrations of the inorganic electrolyte lithium salts in an organic solvent system and corresponding relation with conductivity in the solution system, so that concentration of the inorganic electrolyte lithium salt in the solution can be rapidly detected, the method has the advantages of simple operation and low detection cost, detection can be completed only in 3-5 min, quality control requirement during production can be completely satisfied, and the detection result has good repeatability.

Owner:甘肃立焘新能源科技发展有限公司

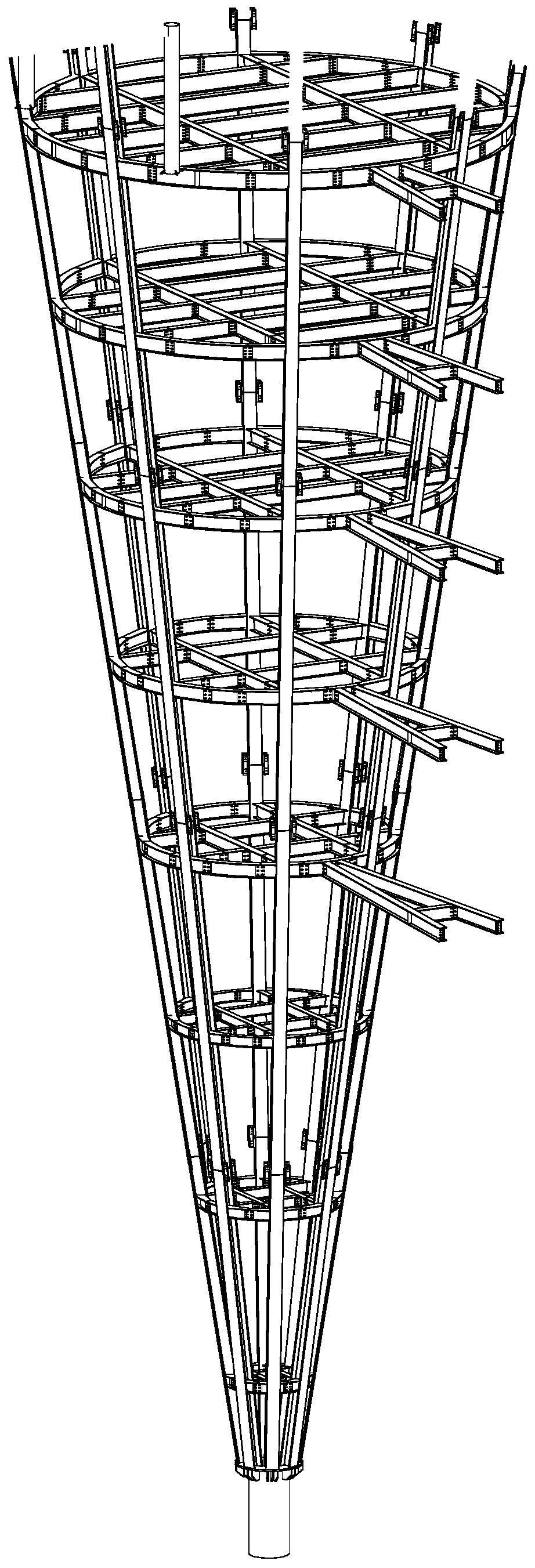

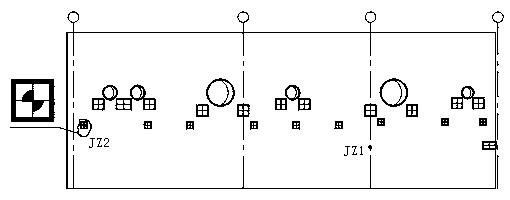

Method for checking position of prefabricated steel component based on three-dimensional scanner technology

InactiveCN110095112AImprove securityCheck flexibleActive open surveying meansComputer scienceInspection method

The invention relates to a method for checking the position of a prefabricated steel component based on a three-dimensional scanner technology. More than three measurement targets are set; a scanner is erected, a prefabricated component is scanned, and data of the scanner are read; fitting of feature points of the prefabricated component is performed, and theoretical coordinates of the feature points are calculated; the theoretical coordinates and the feature points are matched to obtain a spatial stereoscopic part of the prefabricated component; and comparison with a theoretical position is performed to obtain an offset of the prefabricated component. According to the invention, a problem of difficult quality checking of the prefabricated three-dimensional complex prefabricated componentsin the workshop is solved. With the provided method, an accurate inspection result can be obtained and thus the basis is provided for adjusting the actual position of the on-site installation. Moreover, erection becomes flexible and measurement becomes convenient; space of other construction processes is not occupied; and the demand of the construction schedule optimization is satisfied.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

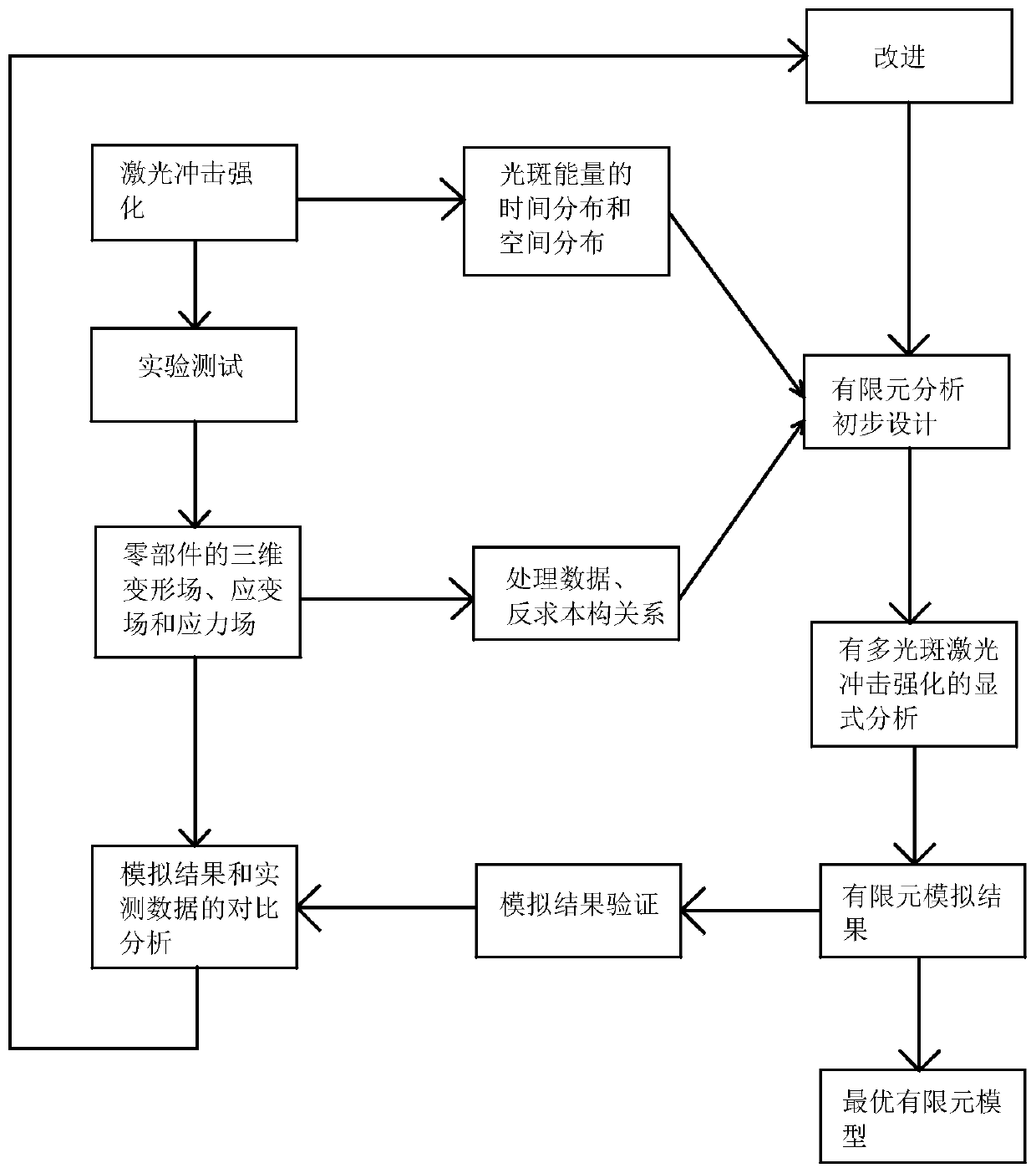

Simulation method based on collected laser shock data and strengthening quality control device

PendingCN110162834AIncrease credibilityMeet the needs of quality controlDesign optimisation/simulationSpecial data processing applicationsElement modelLight spot

The invention relates to a simulation method based on collected laser shock data and a strengthening quality control device. The method comprises the following steps: using a laser shock strengtheningsystem to strengthen a part; collecting light spot parameters generated in the strengthening process; detecting a three-dimensional deformation field, a strain field and a stress field of the part soas to obtain measured data, and reversely solving a constitutive relation of the part in a high strain rate state; generating preliminary design of laser shock peening of the part according to the light spot parameters and the constitutive relation; performing finite element explicit analysis of multi-spot laser shock peening on the preliminary design to obtain a numerical simulation result; comparing and analyzing the simulation result and the measured data, and if the calculated error value is beyond the allowable range, improving the initial design of the finite element analysis until theerror value is within the allowable range to obtain the optimal finite element model. According to the method, a result obtained through finite element simulation analysis has very high credibility, and the control device can well meet the requirement of quality control.

Owner:GUANGDONG LASER PEENING TECH CO LTD

Pipeline position detection method based on three-dimensional scanning

ActiveCN111504225ASolve inspection problemsImprove securityImage analysisNuclear energy generationData transformationQuality control

The invention relates to a pipeline position detection method based on three-dimensional scanning. The method comprises the following steps of selecting a plurality of control reference points on a wall, simultaneously setting the target markers, measuring the coordinates of the control reference points in a construction coordinate system, scanning the position of a pipeline, scanning a referencepoint target at the same time, converting the scanning data into the construction coordinate system, intercepting the scanning data of the pipeline, sorting the pipeline data according to a wall body,selecting a section of section data according to requirements, dividing into the pipe inner side data and the pipe outer side data according to another column of data, and respectively calculating the pipeline center coordinates according to assumed theoretical radiuses to obtain the pipeline center and radius actual values. According to the invention, an accurate detection result can be obtained, the problem of inspection of the pipeline position in nuclear power construction, especially when the pipeline amount is very large, is solved, the inspection safety of the pipeline at high altitudeis improved, the detection is flexible, the measurement is convenient, and the quality control requirement of on-site construction can be met.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

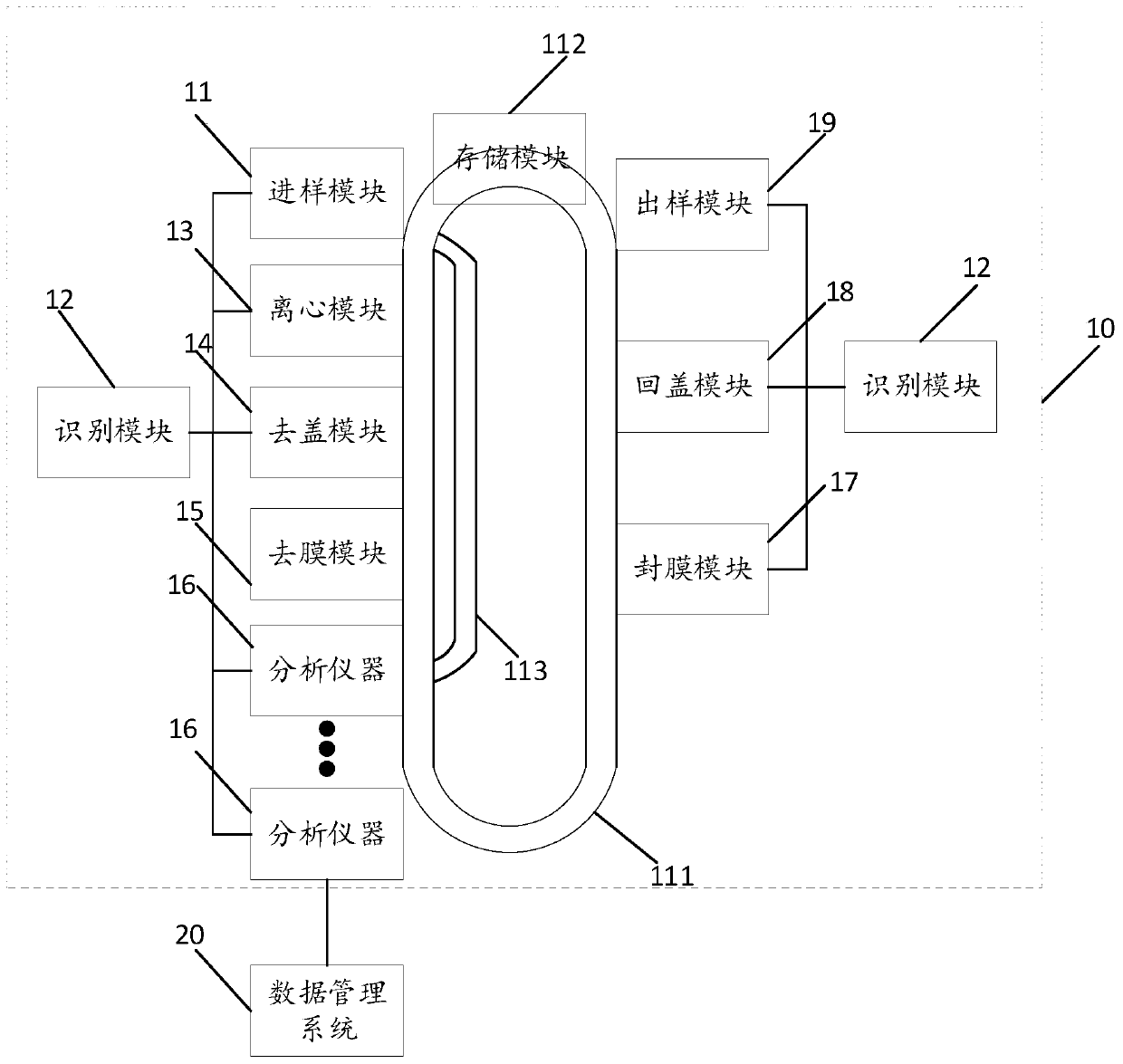

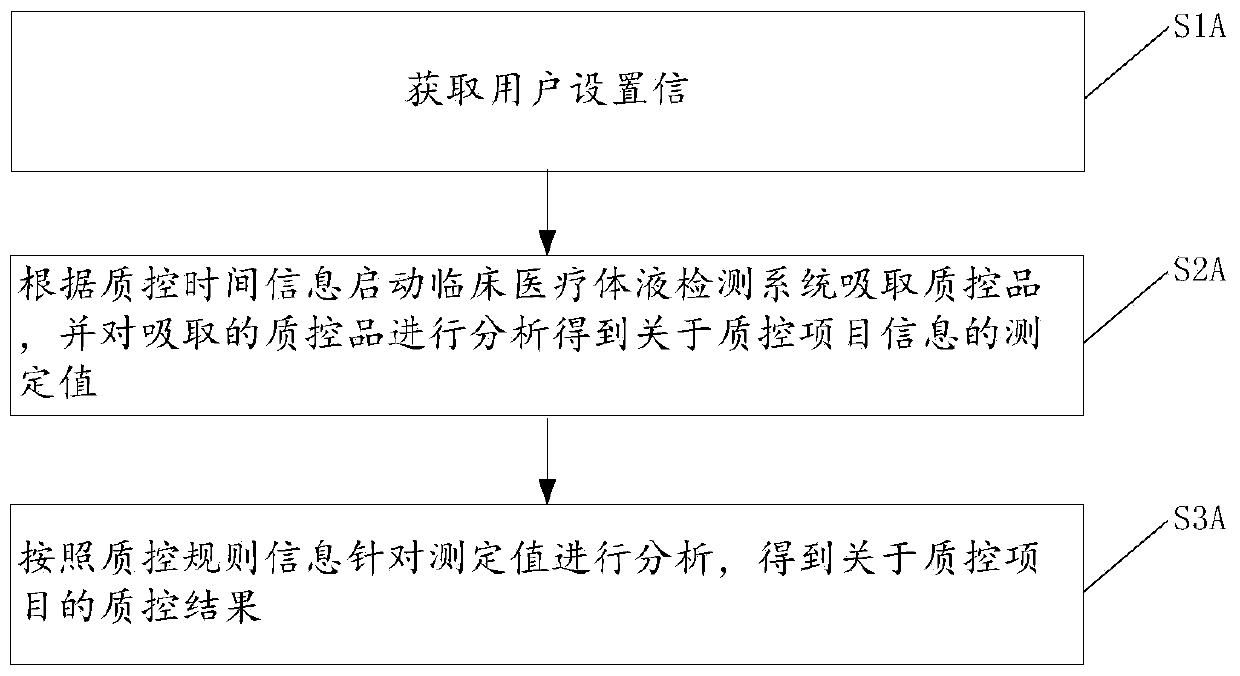

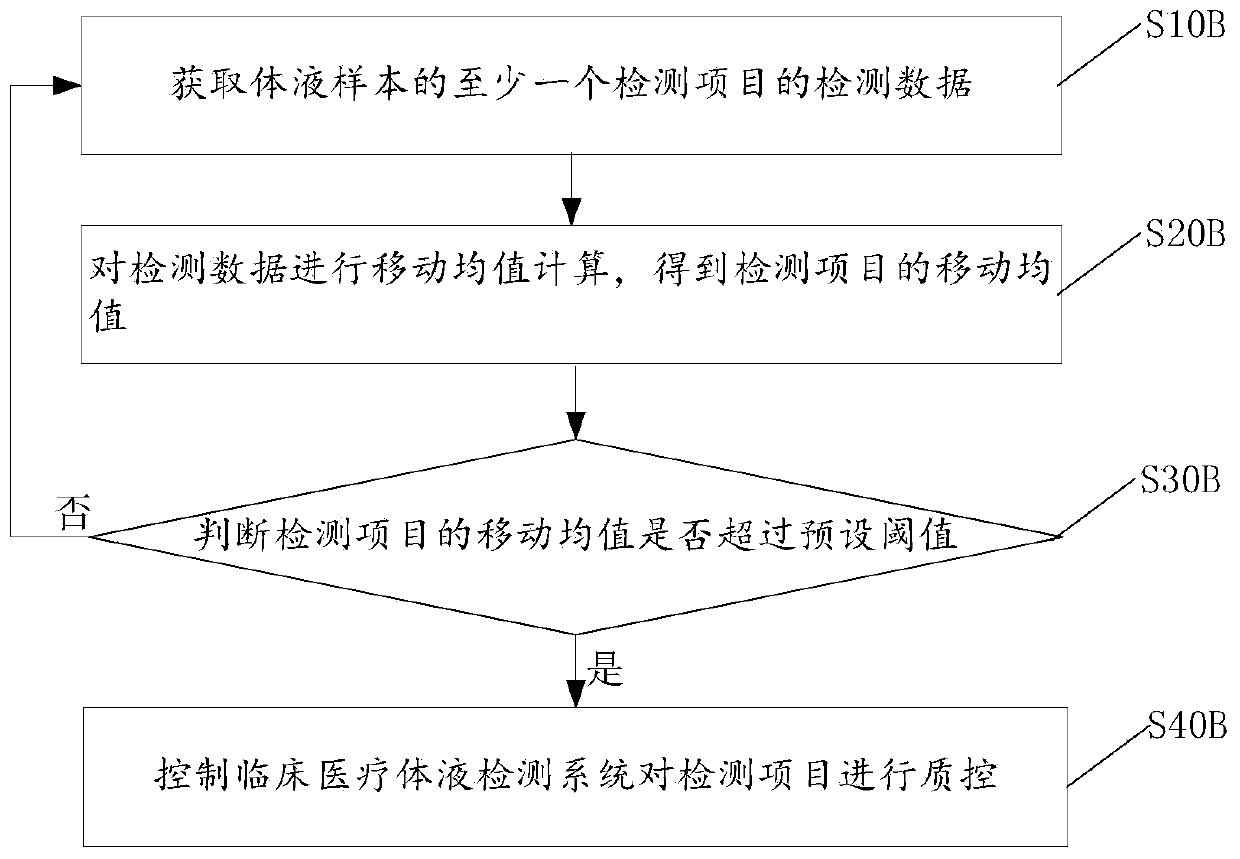

Personalized clinical examination quality control method and equipment

The invention discloses a personalized clinical examination quality control method and equipment, and the method comprises the steps: obtaining user setting information which comprises quality controlproject information, quality control rule information corresponding to the quality control project information, and quality control time information; starting a clinical medical body fluid detectionsystem to suck a quality control product according to the quality control time information, and analyzing the sucked quality control product to obtain a measured value about the quality control item information; and analyzing the measured value according to the quality control rule information to obtain a quality control result about a quality control item.

Owner:BEIJING SIGHTNOVO MEDICAL TECH CO LTD

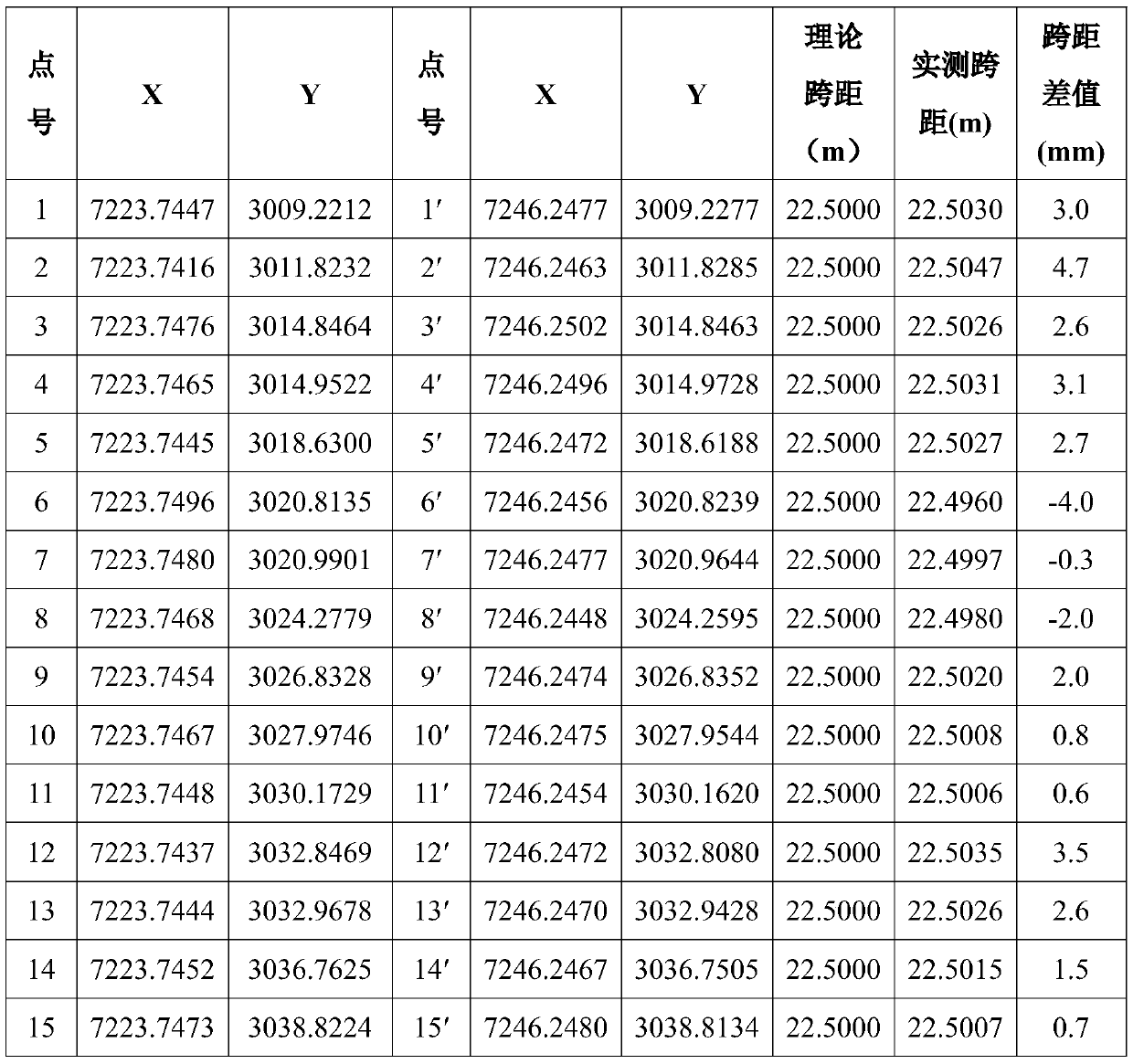

Non-fixed measuring station truss vehicle track position checking method

InactiveCN110207638AAvoid occupyingImprove construction progressSurveying instrumentsQuality controlTotal station

The present invention relates to the technical field of civil construction, and provides a non-fixed measuring station truss vehicle track position checking method. The method comprises following steps: setting a station of a total station, measuring coordinates of a starting point and an end point of a track, calculating azimuth angle of the starting point and the ending point, rotating azimuth angle of the total station to the azimuth angle of the starting point and the ending point, setting the azimuth angle of the total station to zero, measuring three-dimensional coordinates of each detection point, calculating measured span, and comparing the measured span value with a theoretical span value to obtain a deviation value. In the process of checking track position, the method can set upthe total station according to actual situations of a scene and checking elements, to adapt to the actual situation of a construction site, the method can indirectly display mutual relationship between tracks, visually display the span value between the tracks, has simple operation, reliable data, greatly improves safety of checking on the position and the span, and helps to meet the need of quality control of the on-site construction.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

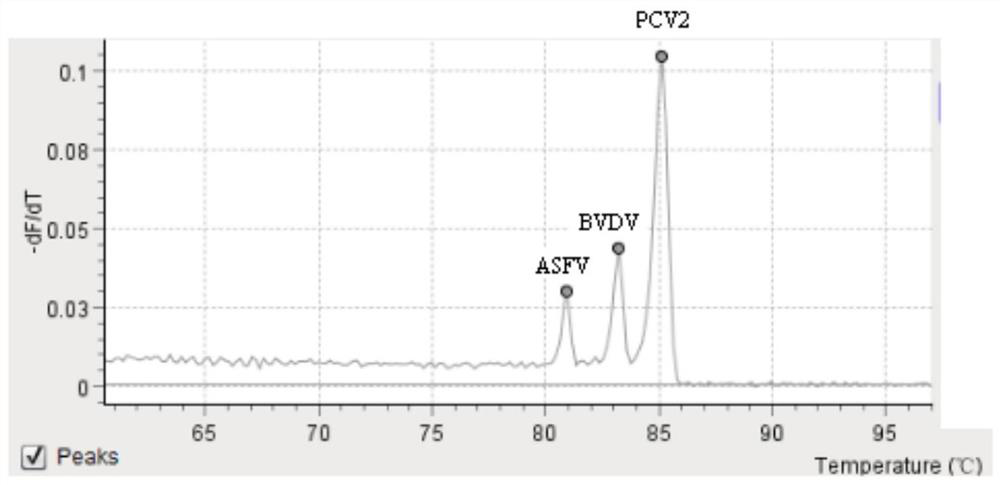

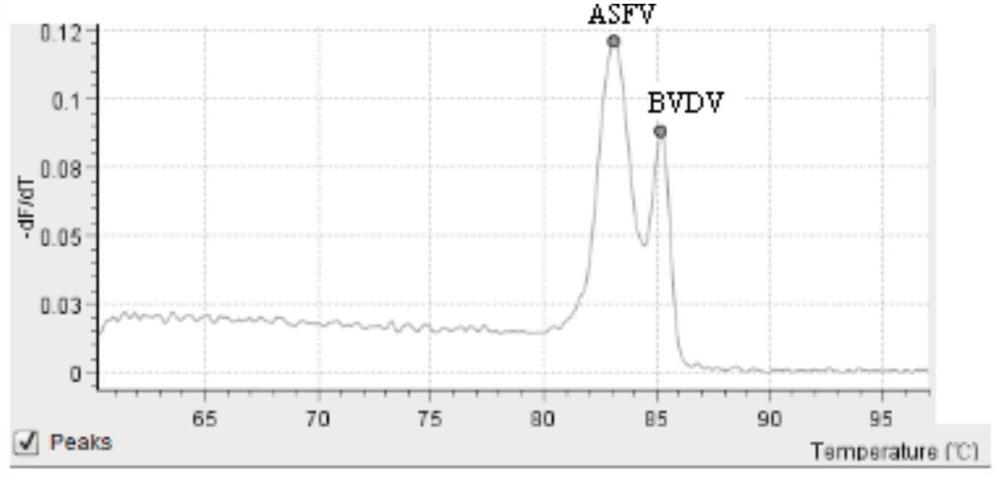

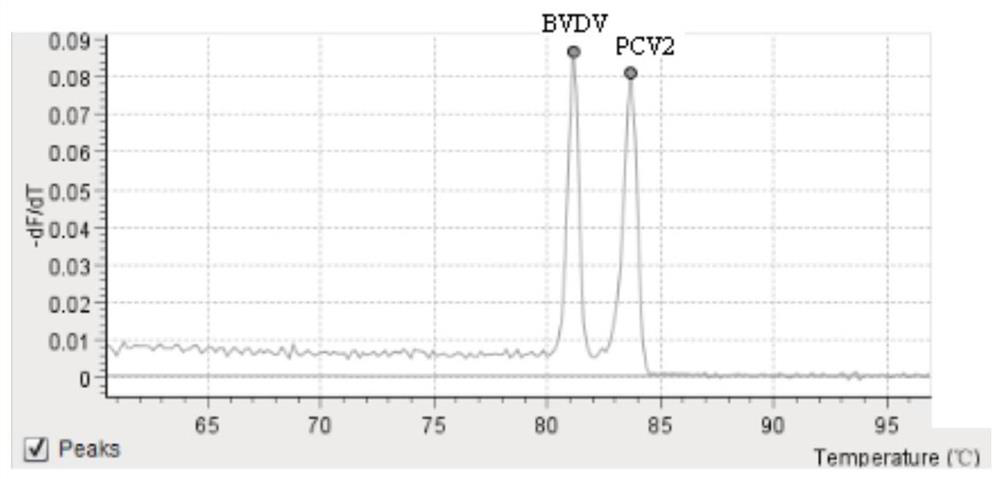

Primer for rapidly detecting exogenous virus in porcine pseudorabies live vaccine and application of primer in kit

InactiveCN112877479AGood use basicsEasy to operateMicrobiological testing/measurementMicroorganism based processesClassical swine fever virus CSFVBovine Viral Diarrhea Viruses

The invention provides a primer for rapidly detecting an exogenous virus in a porcine pseudorabies live vaccine and application of a primer in a kit. The primer comprises a specific primer I aiming at an African swine fever virus, a specific primer II aiming at a bovine viral diarrhea virus and a specific primer III aiming at a porcine circovirus type 2; the primers are applied to the kit, and rapid screening and detection of three pathogens, namely, African swine fever virus (ASFV), bovine viral diarrhea virus (BVDV) and porcine circovirus type 2 (PCV2), are simultaneously completed in a reaction system; by arranging the detection primers, the specificity, the stability and the sensitivity for detecting the ASFV, the BVDV and the PCV2 can be improved; when being applied, the kit has the advantages of simplicity in operation, short detection time and no limitation of the level of detection personnel and the level of a laboratory.

Owner:SHANDONG BINZHOU ANIMAL SCI & VETERINARY MEDICINE ACADEMY

Truss crane track inspection method based on three-dimensional scanner technology

InactiveCN111380475ASolve inspection problemsAccurately get the coordinate valueUsing optical meansRail inspectionTrackway

The invention discloses a truss crane rail inspection method based on a three-dimensional scanner technology. The method comprises the following steps: selecting three or more control reference pointson a cylinder, measuring coordinates of the control reference point in a construction coordinate system; erecting a scanner, and scanning the position of the truss crane rail; converting the scanningdata into a construction coordinate system; selecting the scanning data of the truss crane and independently storing the scanning data as scanning data of the truss crane, cutting out the section ofthe track beam every 2m, extracting three-dimensional coordinates of points on the two sides of the section, comparing coordinates and elevation difference values of the same positions of track points, obtaining the actual distance and elevation difference of the track gauge, and obtaining a deviation value is obtained through comparison of the theoretical distance and the actual distance. According to the method, an accurate detection result can be obtained, so a basis is provided for inspection and acceptance of the truss crane rail, the problem of inspection of the truss crane rail in construction is solved, the inspection safety of the truss crane rail at high altitude is improved, the detection is flexible, the measurement is convenient, and the quality control requirement of field construction is met.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

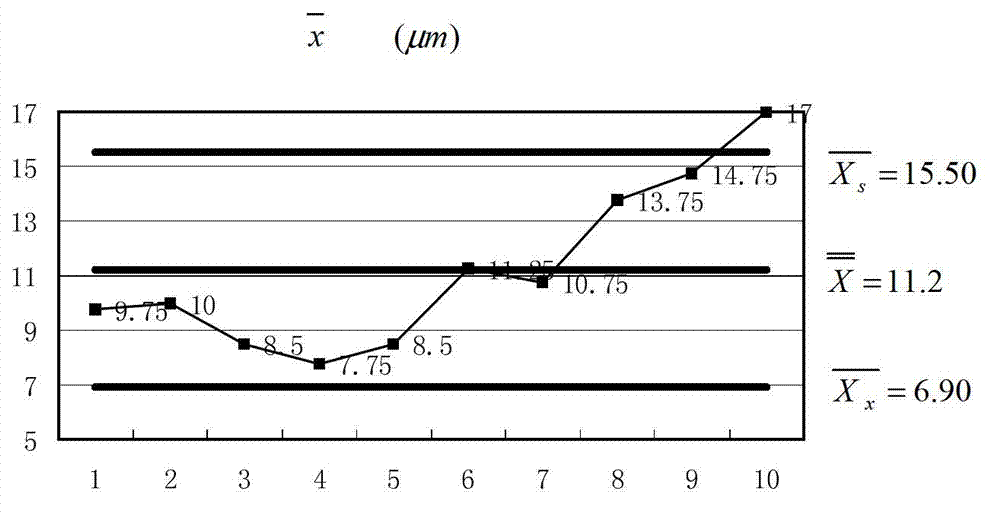

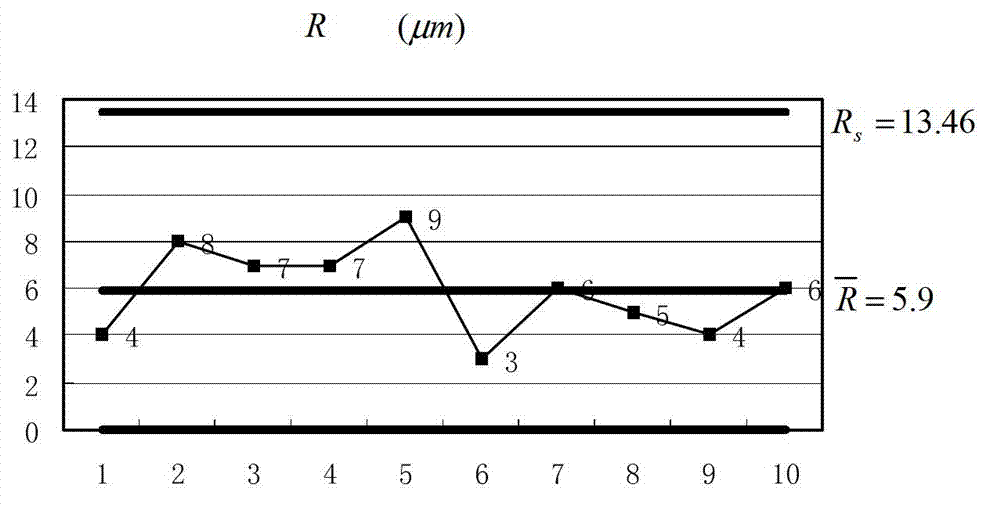

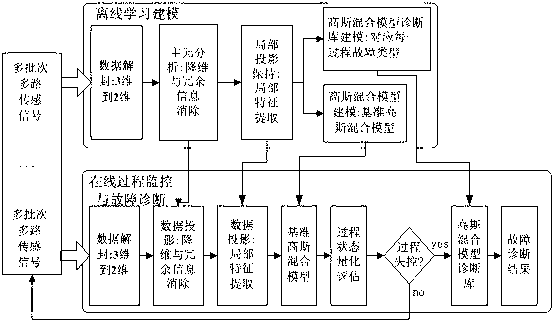

State monitoring and fault diagnosis method for large-scale semiconductor manufacture process

InactiveCN102361014BEasy to useAvoid defects that are not easily collectedSemiconductor/solid-state device testing/measurementData setDiagnosis methods

Owner:SHANGHAI UNIV

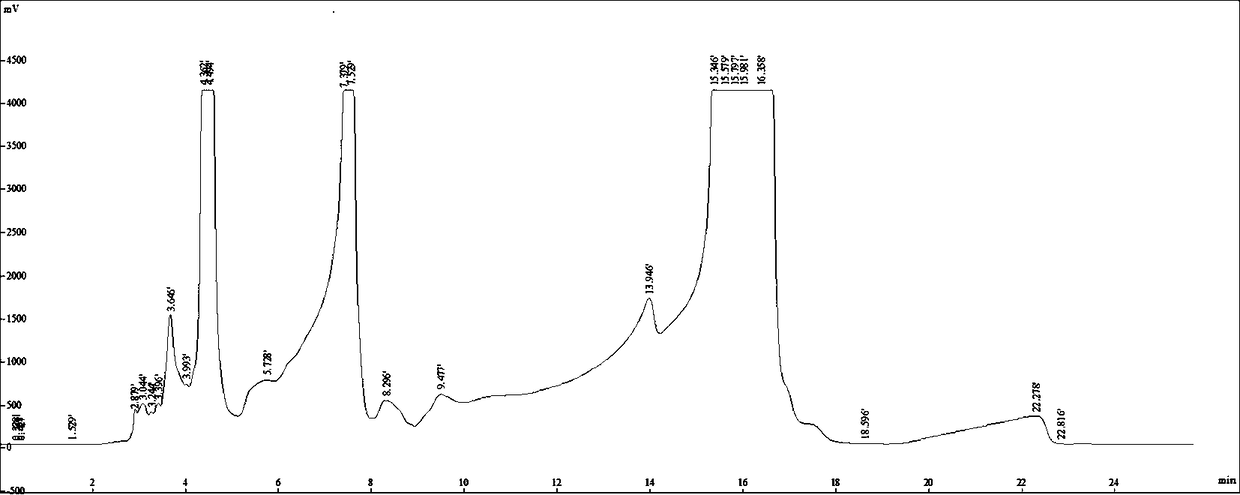

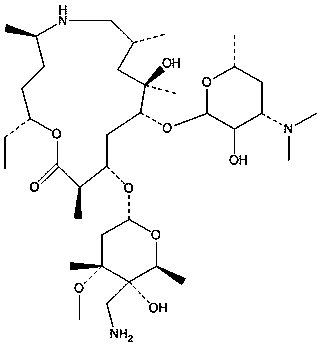

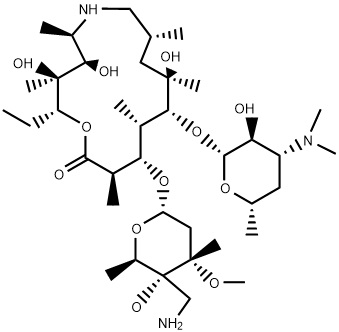

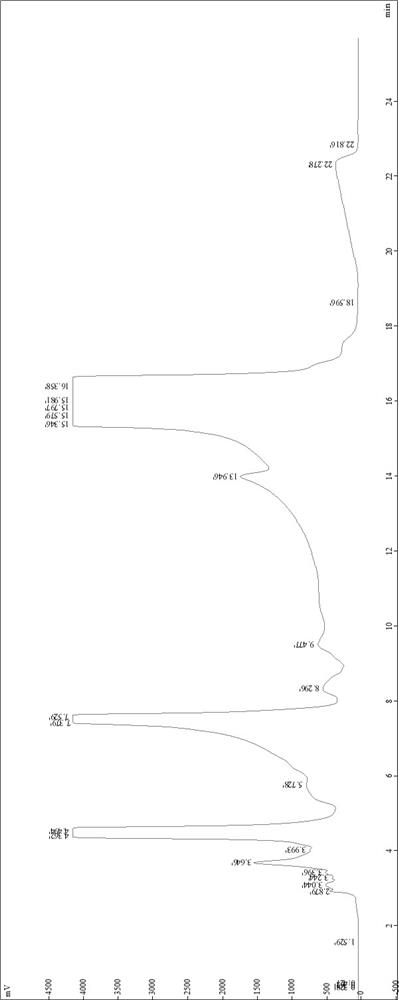

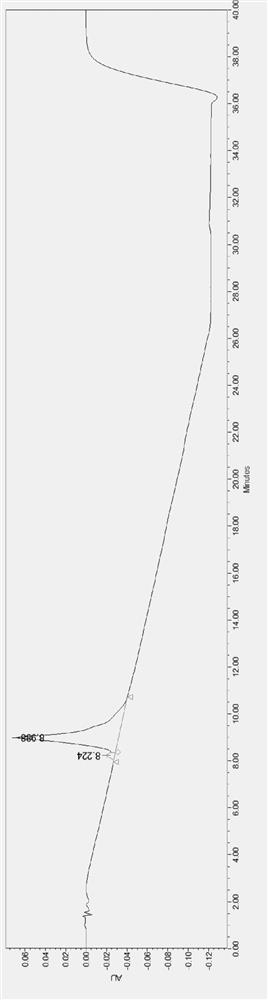

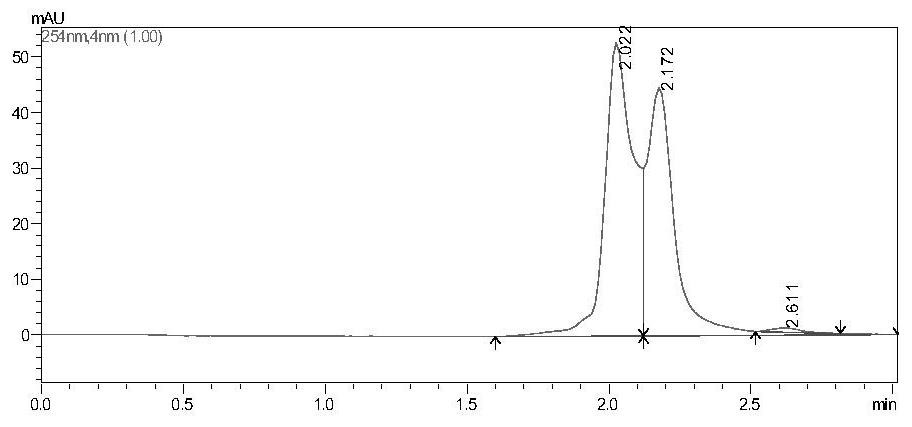

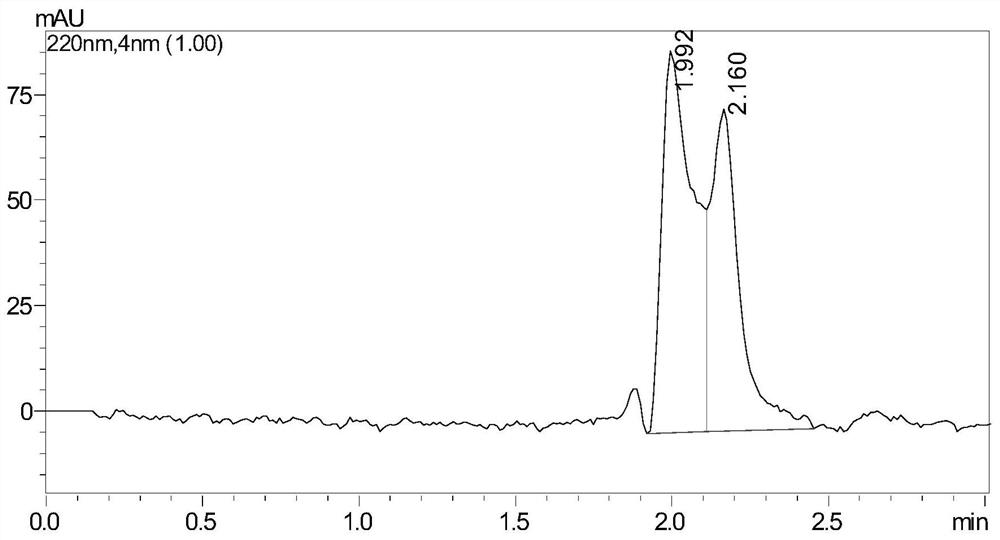

Method for separating related substances of tulathromycin

InactiveCN109456372AEfficient separationMeet the needs of quality controlSugar derivativesSugar derivatives preparationActivated carbonDistribution Volume

The invention provides a method for separating related substances of tulathromycin. High performance liquid chromatography is adopted, a to-be-separated object is washed in a chromatographic column through a flow phase, a qualified fraction is subjected to decompression distillation, and after extraction and desalting, an organic layer is taken to be subjected to decompression concentration to bedried. Before extraction, the qualified fraction is treated, the qualified fraction is subjected to high-pressure homogenization or ultrasonic crushing, the particle size is decreased, the pH is adjusted, activated carbon for an injection is added and stirred, decarbonization is conducted, then filtering is conducted through a filter membrane, thus the apparent distribution volume is increased, and impurities in the fraction are better separated out; and according to the separation method, the impurities generated in the synthesis and degradation processes of the tulathromycin can be effectively separated, the production batch is stable, the quality is reliable, the production period is short, the single-time preparation yield is high, the impurity weight control needs are met, and a goodfoundation is laid for the study of unknown impurities of the tulathromycin.

Owner:JIANGSU WEI LING BIOCHEM TECH CO LTD

Method for separating and purifying tulathromycin D

PendingCN112079890AEfficient separationMeet quality control needsSugar derivativesSugar derivatives preparationActivated carbonFluid phase

The invention provides a method for separating and purifying tulathromycin D. The method comprises the following steps: eluting a to-be-separated substance in a chromatographic column by using a mobile phase by adopting high performance liquid chromatography, performing reduced pressure distillation on qualified fractions, extracting and desalting, and performing reduced pressure concentration onan organic layer until the organic layer is dried. According to the method disclosed by the invention, the qualified fractions are treated before extraction, the qualified fractions are subjected to high-pressure homogenization or ultrasonic grinding, the particle size is reduced, the pH value is regulated, activated carbon for injection is added, stirring and decarburization are performed, filtration is performed by virtue of a filter membrane, the apparent distribution volume is improved, and impurities in the fractions are well separated. According to the separation method, the impurities produced in the synthesis and degradation process of the tulathromycin can be effectively separated, the production batch is stable, the quality is reliable, the production cycle is short, the single preparation yield is high, the impurity quality control requirements are met, and a good foundation is laid for research of unknown impurities of the tulathromycin.

Owner:JIANGSU WEI LING BIOCHEM TECH CO LTD

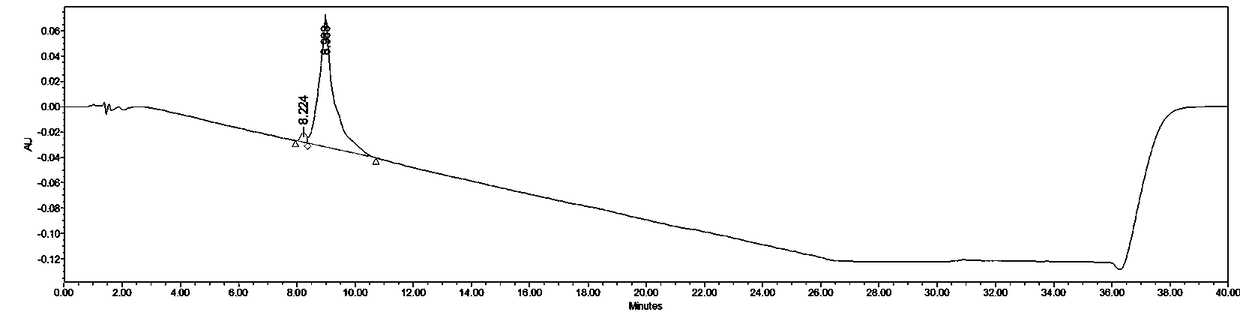

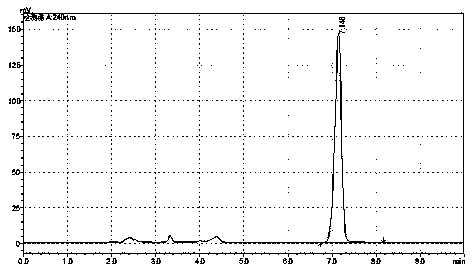

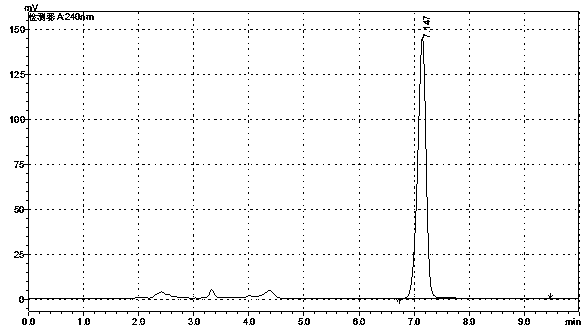

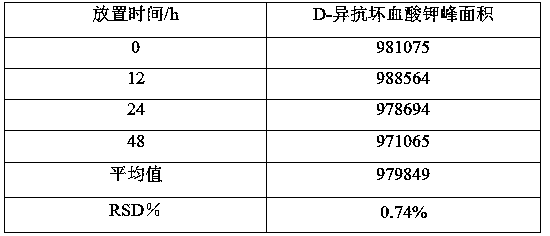

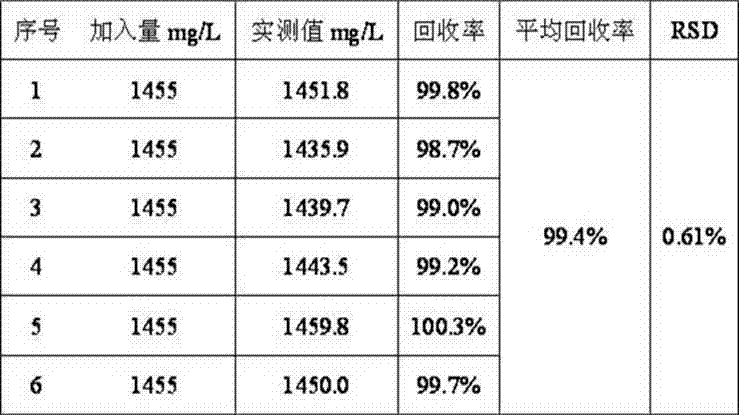

High performance liquid detection method of D-potassium erythorbate

The invention provides a high performance liquid chromatography detection method of D-potassium erythorbate, and the detection chromatographic conditions are as follows: high performance liquid chromatography is used for analysis, and a polyacrylamide bonded silica gel chromatographic column is adopted; a mixed solution of a phosphate buffer solution and acetonitrile is taken as a mobile phase; amixed solution of acetonitrile and water is used as a diluent, and an ultraviolet detector is used for detection. The sample pretreatment steps are simple, the D-potassium erythorbate does not need tobe derived, the detection time is short, and the method provided by the invention has high sensitivity; according to the method provided by the invention, the content of the D-potassium erythorbate can be well measured, and the requirement on quality control in the production process can be met.

Owner:新拓洋生物工程有限公司

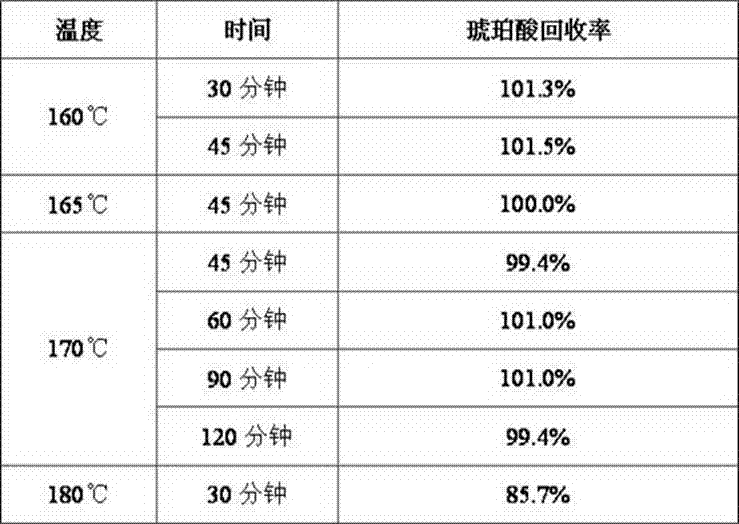

Method for detecting succinylation modified gelatin and combination succinic acid in its injection

InactiveCN103163242ADoes not affect recoveryMeet the needs of quality controlComponent separationMicrowaveSuccinylation

The invention relates to a method for detecting succinylation modified gelatin and combination succinic acid in its injection, which comprises the following steps: 1) using a microwave hydrolysis method to hydrolyze the succinylation modified gelatin and the combination succinic acid in its injection; and 2) detecting succinic acid in the solution obtained in the step (1) by a chromatography method.

Owner:浙江康乐药业股份有限公司

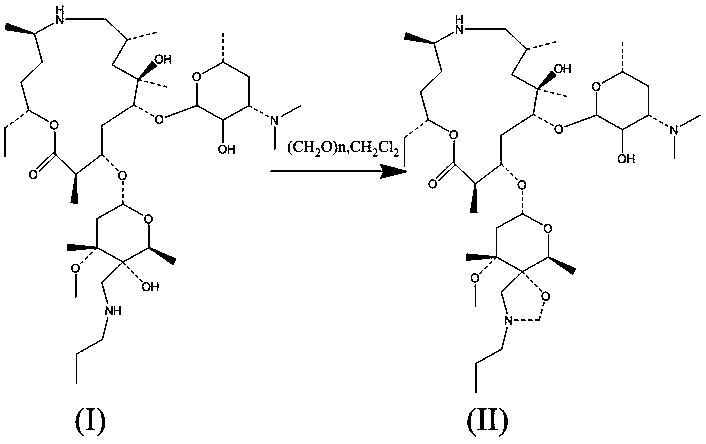

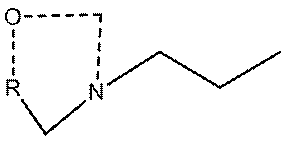

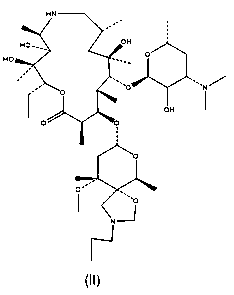

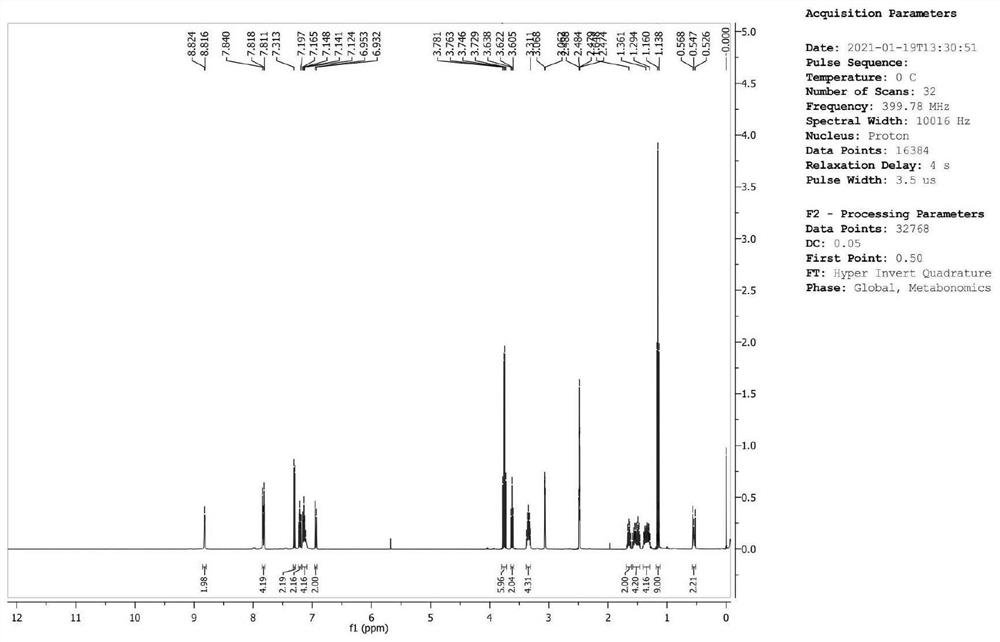

A method for synthesizing and purifying Tyramycin impurity C

ActiveCN109535211BStable in natureHigh puritySugar derivativesSugar derivatives preparationCombinatorial chemistryAmmonium bromide

The present invention discloses a method for synthesizing and purifying a tulathromycin impurity C. The method uses tulathromycin as a raw material, synthesizes the tulathromycin impurity C easy to beproduced in a production process of the tulathromycin, and facilitates studies of structures and properties of the impurity. The synthesized tulathromycin impurity C has stable properties and relatively high purity, and can meet research requirements of the structures and properties of the tulathromycin impurity in the industry. The method is easy to operate, synthesis is easy to control, and themethod meets quality control requirements of the impurity, uses methylene chloride as a solvent, uses paraformaldehyde or formaldehyde, enables reaction to be more thorough, and improves conversion efficiency of the tulathromycin under catalysis of trace tetrabutylammonium bromide. In a case of recrystallization, an appropriate ratio is used, so that a tulathromycin impurity C crude product is more complete in purification and purity of the tulathromycin impurity C crude product is improved.

Owner:JIANGSU WEI LING BIOCHEM TECH CO LTD

Quality control method of traditional chinese medicine preparation for treating traumatic injury and rheumatism ostealgia

ActiveCN101138594BMeet the needs of quality controlEasy qualityComponent separationAntipyreticInjury causeRheumatism

The present invention discloses a quality control method of Chinese medicine for treating traumatic injuries and rheumatic pain. The present invention combines the index component content mensuration and the thin-layer chromatography detection method for Chinese medicine, so as to achieve the aim of controlling and evaluating the quality of the Chinese medicine. Compared with the traditional quality control method, the method provided by the present invention is more scientific, reasonable and effective. In terms of operation, the method provided by the present invention has the advantages ofsimple operation, accuracy and reliability, high precision and high practical value.

Owner:广西壮族自治区花红药业集团股份公司

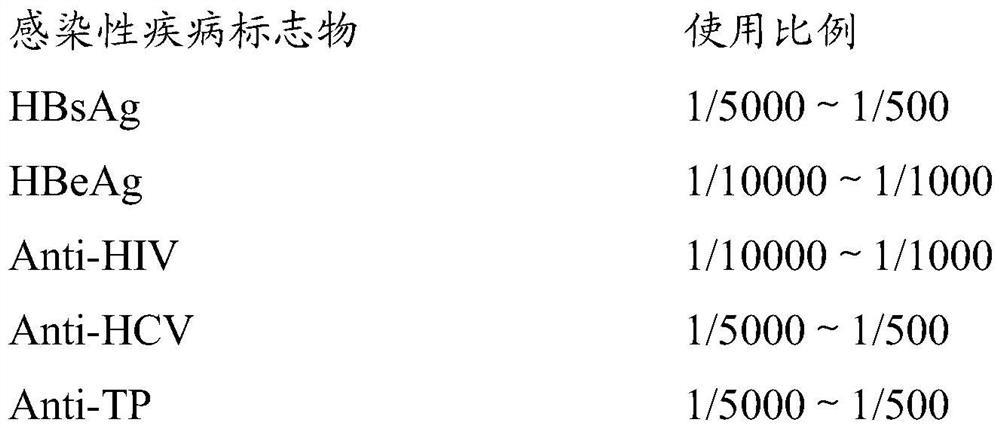

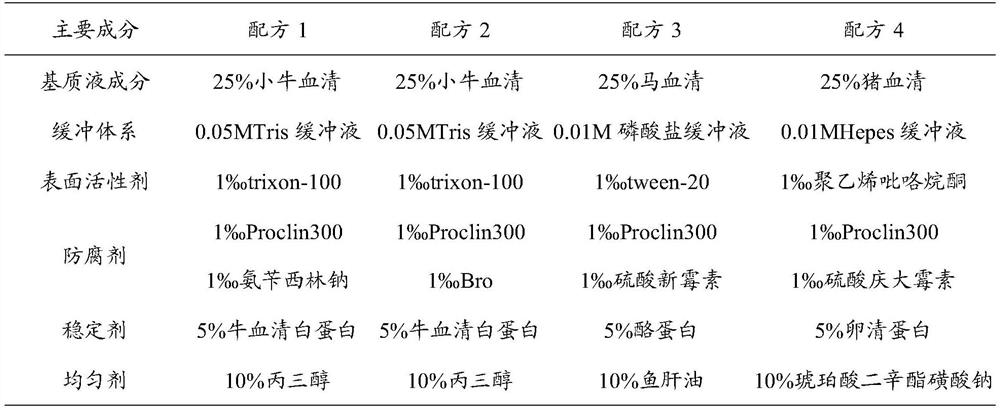

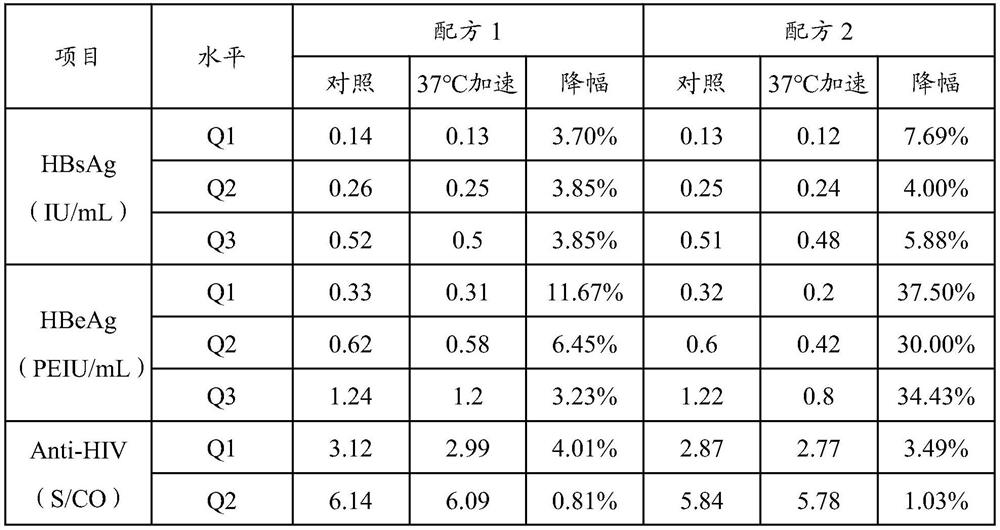

Infectious disease marker composite quality control product, detection reagent and detection kit

PendingCN112067810AImprove accessibilityGrowth inhibitionImmunoassaysPathogenic microorganismMicrobiology

The invention relates to the field of biological examination, in particular to an infectious disease marker composite quality control product, a detection reagent and a detection kit. The quality control product is high in compounding degree, a protein buffer solution is selected as a matrix, raw materials and auxiliary materials used in the preparation process are inactivated, and harm of variouspotential pathogenic microorganisms is eliminated. Meanwhile, the quality control product is designed to be applicable to instruments of mainstream manufacturers on the market, is wide in applicationrange and can meet the detection requirements of infectious disease markers on the market. The quality control product can be used for quality control of five infectious disease markers in the detection process at the same time, and an accurate basis is provided for diagnosis of clinical diseases; and moreover, the uniformity and the stability are good, the clinical operation is facilitated, thepossibility of misoperation is reduced, the cost is saved, and reliable guarantee is provided for the accuracy of a clinical examination result.

Owner:郑州标源生物科技有限公司

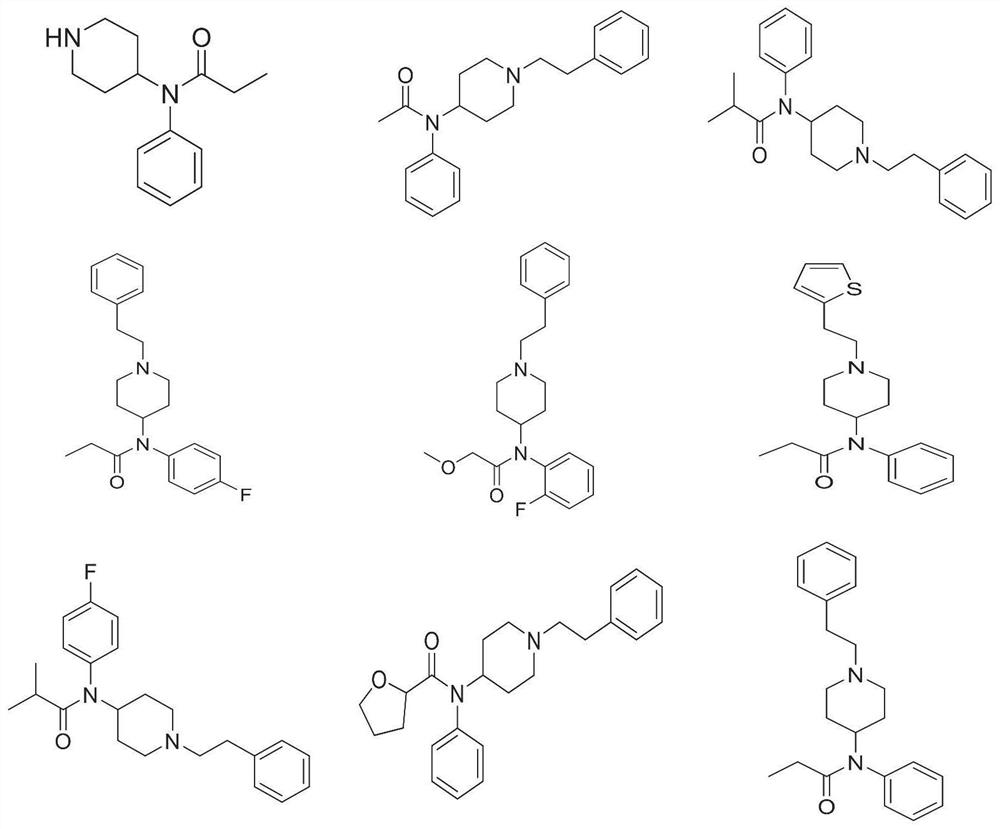

Sulfur spacer arm (R)-BIONL CSP filler and preparation method thereof

PendingCN114534311AGood stabilityStable chiral recognition abilityComponent separationOther chemical processesRactopamineDrug

The invention discloses a sulfur spacer (R)-BINOL CSP filler as well as a preparation method and application thereof. The structural formula of the sulfur spacer (R)-BINOL CSP is shown in the specification. In the formula, the structural formula of the silica gel carrier after hydrogen is removed is represented. The filler can separate chiral compounds of various structure types, has good stability, is suitable for being used as a high performance liquid chromatography filler, can resolve three chiral compounds of thalidomide, salbutamol and ractopamine under the condition of a polar mobile phase, has stable chiral recognition capability, and can be used as a high performance liquid chromatography filler for separating chiral compounds of thalidomide, salbutamol and ractopamine. The requirements of enantiomer separation and analysis of chiral drugs and quality control in the production and clinical use process can be met.

Owner:KUNMING MEDICAL UNIVERSITY

A pipeline position detection method based on 3D scanning

ActiveCN111504225BSolve inspection problemsImprove securityImage analysisNuclear energy generationLocation detectionData transformation

The invention relates to a pipeline position detection method based on three-dimensional scanning, which includes selecting a plurality of control reference points on the wall, setting target marks at the same time, measuring the coordinates of the control reference points in the construction coordinate system, and scanning the position of the pipeline , and scan the reference point target at the same time, convert the scanned data into the construction coordinate system, intercept the scanned data of the pipeline, sort the pipeline data according to the wall, select a section of cross-section data according to the requirements, and separate the inner data of the pipe and the data of the inner side of the pipe according to another column of data For the data outside the pipe, calculate the coordinates of the center of the pipe from the assumed theoretical radius to obtain the actual value of the center and radius of the pipe. The invention not only can obtain accurate detection results, but also solves the problem of pipeline position inspection in nuclear power construction, especially when the pipeline volume is particularly large, and improves the safety, flexible detection, and convenient measurement of pipelines located at high altitudes. Help meet the quality control needs of on-site construction.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

Preparation method and application of fentanyl medicine hair standard substance

PendingCN114705780AEasy and fast handlingHigh sensitivityComponent separationAbuse drugsPharmaceutical drug

The invention belongs to the technical field of analytical chemistry, and particularly relates to a preparation method and application of nine fentanyl drug standard substances in a hair sample, and the preparation method comprises the following steps: collecting an adult hair sample, washing, drying, soaking, cleaning, drying, crushing into dark brown powder and the like. The standard substance meets the requirements of forensic and clinical laboratories for fentanyl drug standard substances, the preparation method is simple, the valuing method is high in sensitivity, good in accuracy and high in specificity, and the standard substance can be used as a valuing method for the fentanyl drug matrix standard substance in hair and used for research and development of the standard substance. The method is applied to forensic abuse drug detection and laboratory quality control.

Owner:NAT INST OF METROLOGY CHINA

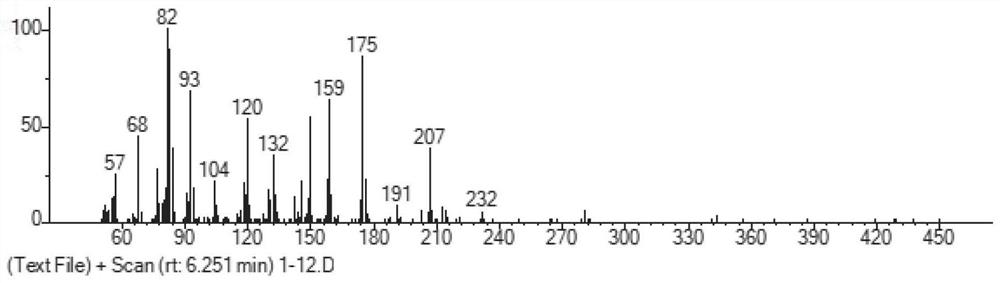

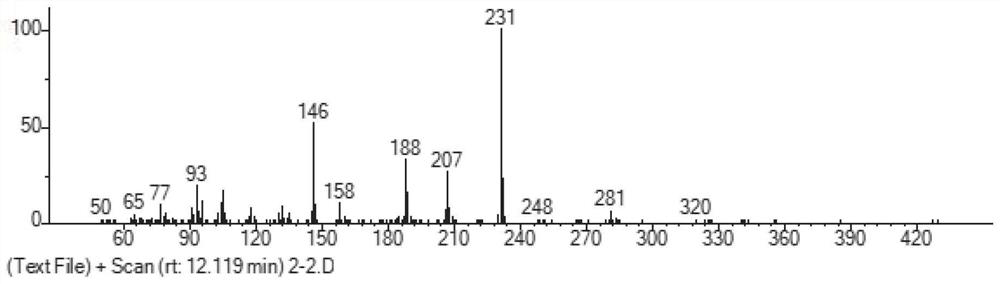

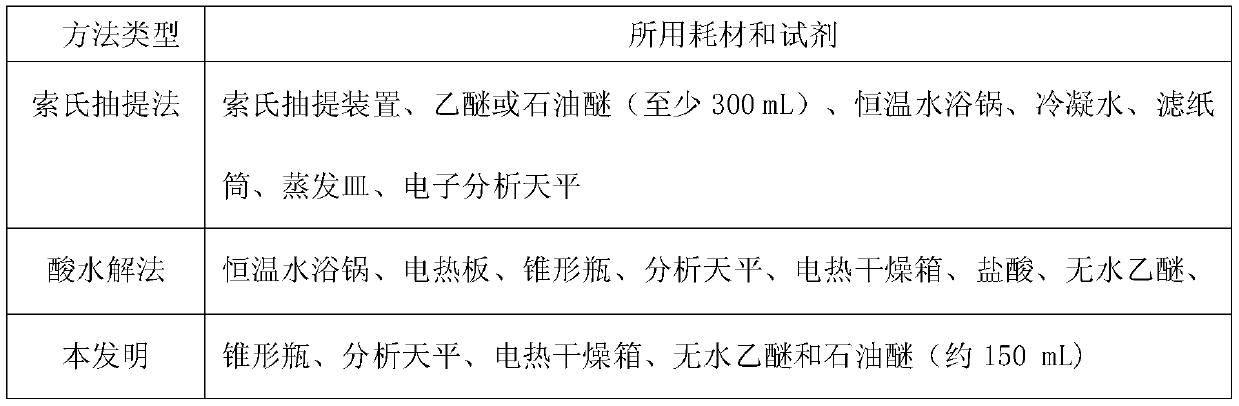

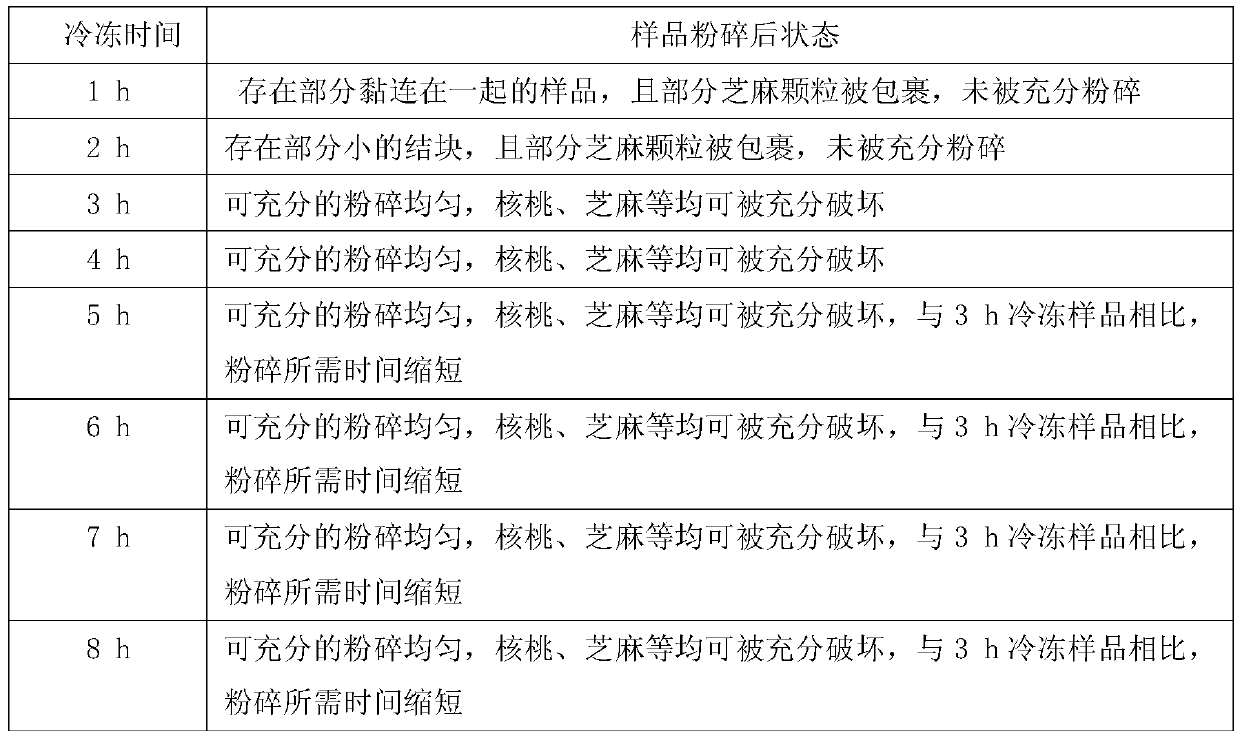

Method for measuring fat content of donkey-hide gelatin cake products

InactiveCN110470566AMeet the needs of quality controlPromote healthy developmentWeighing by removing componentWater bathsBottle neck

The invention discloses a method for measuring the fat content of donkey-hide gelatin cake products. The method comprises the following steps that: a to-be-detected donkey-hide gelatin cake product isfrozen for more than 4 hours under temperature of -15 DEG C to -20 DEG C, and the frozen to-be-detected donkey-hide gelatin cake product is crushed, and the crushed to-be-detected donkey-hide gelatincake product is uniformly mixed so as to be used later; a sample is weighed and transferred into a conical flask, water is added into the conical flask, and an obtained mixture is subjected to ultrasonic treatment; anhydrous ether is added, after shaking and vibration are performed, petroleum ether is added, shaking and vibration are performed again, the stopper and bottle neck of the conical bottle are washed with a mixed solvent of petroleum ether and diethyl ether, and the conical bottle stands still, and then a supernate is sucked out and transferred into a fat collecting bottle, and theabove process is repeated twice; and the fat collecting bottle is arranged above a boiling water bath until the supernate in the fat collecting bottle is evaporated to be dried, the fat collecting bottle is dried, the fat collecting bottle is taken out and is cooled in a dryer, and the fat collecting bottle is weighed, the above operation is repeated until the weight of the fat collecting bottle is constant, and the fat content in the sample is calculated. According to the method disclosed by the invention, the preparation problem of the donkey-hide gelatin cake product sample is solved; organic solvents such as concentrated hydrochloric acid and ethanol are not used; heating and condensation treatment are not needed; inspection work can be completed by 1. 5h; inspection cost is reduced; the use of toxic reagents is suppressed; and the efficiency of an experiment is greatly improved.

Owner:SHANDONG INST FOR FOOD & DRUG CONTROL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com