Simulation method based on collected laser shock data and strengthening quality control device

A technology of laser shock strengthening and laser shock, which is applied in the fields of electrical digital data processing, special data processing applications, design optimization/simulation, etc., can solve problems such as costing a lot of time and money, time-consuming and laborious, and achieve high reliability, Good quality control, satisfying the effect of quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

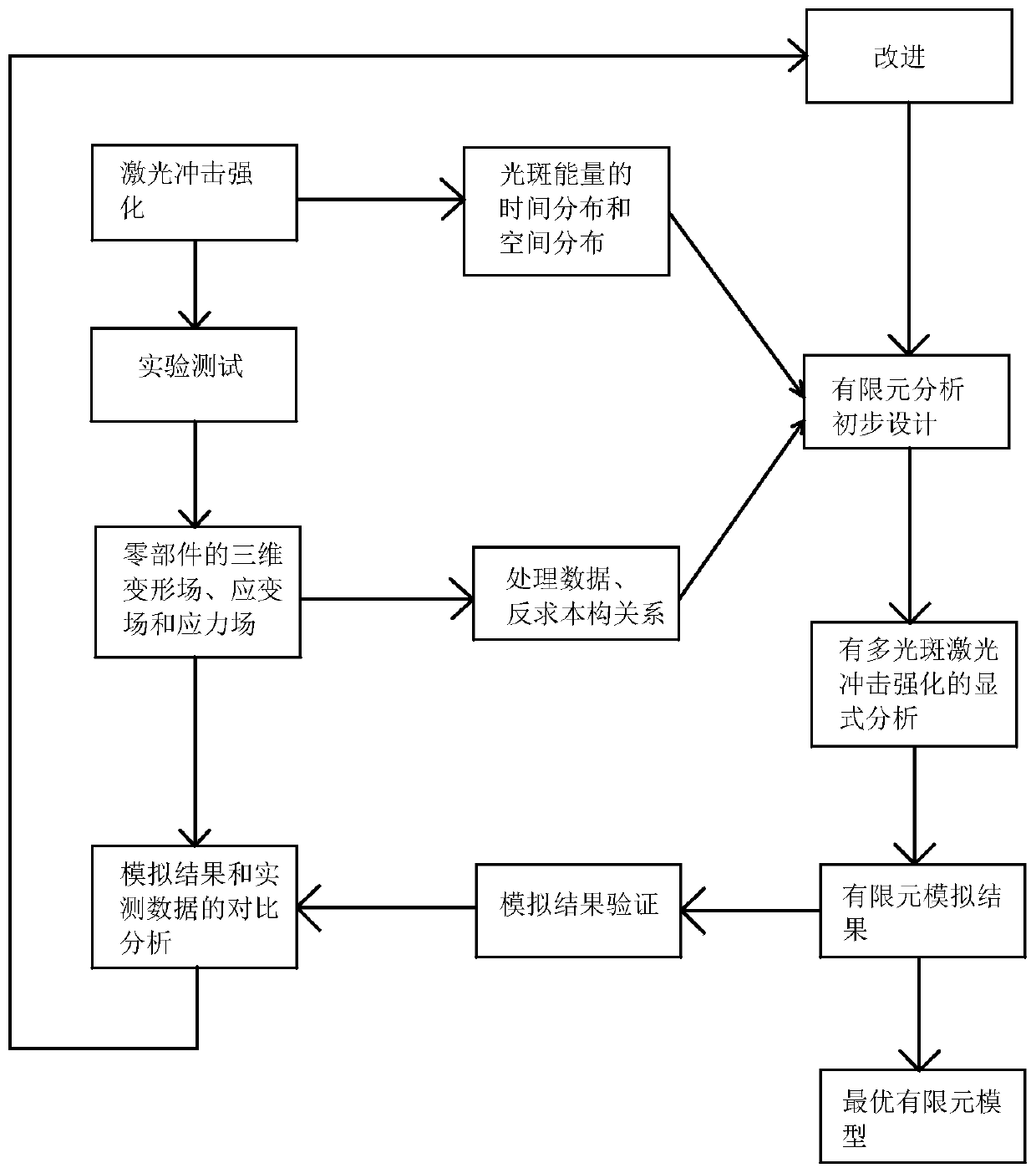

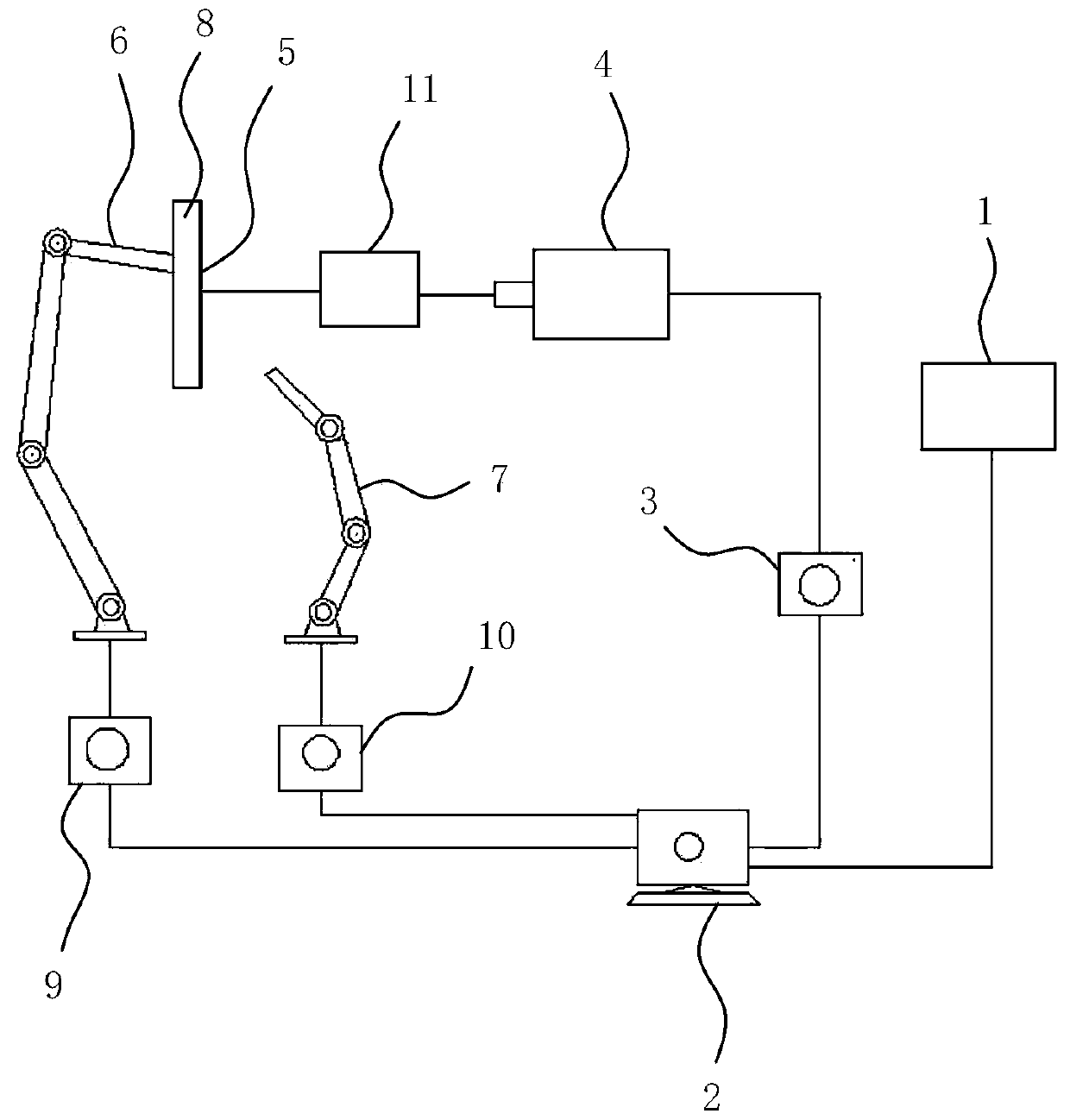

[0023] Such as Figure 1-2 Shown in, a kind of simulation method based on the laser shock data of collection, in one of them embodiment, take the parts and components of the aeroengine impeller that TC4 titanium alloy is made as experimental object, carry out finite element simulation, comprise the following steps:

[0024] a. Use the laser shock strengthening system to process the complex thin-walled blades of the parts, and set the basic processing parameters: the laser energy is 6J, the circular spot size is 6mm, the pulse width is 10ns, the pulse frequency is 5Hz, and the overlap rate 50%;

[0025] b. Using the automatic data collection function of the laser shock peening system, the recorded data includes: the pulse energy of each spot, the pulse width of each spot, the complete time distribution of the selected spot, and the complete spatial distribution of the selected spot. Import the collected spot parameters into MATLAB, fit the spot parameters, obtain the time and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com