A pipeline position detection method based on 3D scanning

A technology of three-dimensional scanning and pipeline location, which is applied in the direction of measuring devices, optical devices, and greenhouse gas reduction, can solve the problems of inconvenient inspection, many measurements, and long inspection time, and achieve obvious convenience in measurement and solve pipeline problems. Detect and apply flexible and convenient effects

Active Publication Date: 2022-05-31

CHINA NUCLEAR IND HUAXING CONSTR

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] There are many equipment and pipelines in nuclear power plants, and there are many pipelines reserved for walls and floors. During the construction process, inspections are frequent and measurements are many. The walls are high and the construction site conditions are poor. Inspections are inconvenient, safety performance is not easy to guarantee, and inspections take a long time. It is not conducive to the optimization of the construction period and cannot ensure the quality of work

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0036]

[0038]

[0040]

[0041] The theoretical radius of points 1 to 13 is 0.1505, and the theoretical radius of points 14 to 31 is 0.16195

[0044]

[0045]

[0046]

[0047]

[0050]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

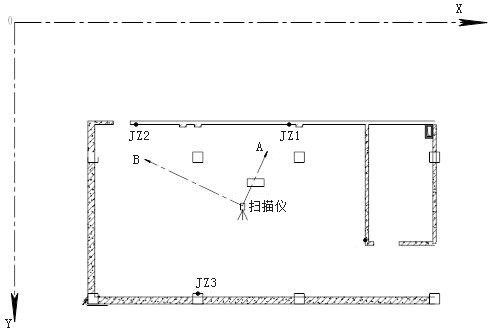

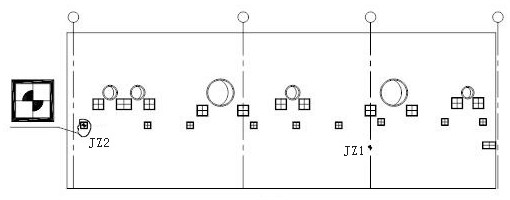

The invention relates to a pipeline position detection method based on three-dimensional scanning, which includes selecting a plurality of control reference points on the wall, setting target marks at the same time, measuring the coordinates of the control reference points in the construction coordinate system, and scanning the position of the pipeline , and scan the reference point target at the same time, convert the scanned data into the construction coordinate system, intercept the scanned data of the pipeline, sort the pipeline data according to the wall, select a section of cross-section data according to the requirements, and separate the inner data of the pipe and the data of the inner side of the pipe according to another column of data For the data outside the pipe, calculate the coordinates of the center of the pipe from the assumed theoretical radius to obtain the actual value of the center and radius of the pipe. The invention not only can obtain accurate detection results, but also solves the problem of pipeline position inspection in nuclear power construction, especially when the pipeline volume is particularly large, and improves the safety, flexible detection, and convenient measurement of pipelines located at high altitudes. Help meet the quality control needs of on-site construction.

Description

A method of pipeline position detection based on 3D scanning technical field The present invention relates to the technical field of nuclear power plant construction, in particular, to a kind of pipeline position based on three-dimensional scanning Detection method. Background technique [0002] There are many plant equipment and pipelines in nuclear power plants, and many pipelines are reserved for walls and bottom plates. During construction, inspections are frequent and measurement times are frequent. The wall is high, the construction site conditions are poor, the inspection is inconvenient, the safety performance is not easy to guarantee, and the inspection takes a long time, which is not conducive to The optimization of the construction period cannot ensure the quality of the work. SUMMARY OF THE INVENTION In view of the above-mentioned problems, the object of the present invention is the problem that the background technology proposes, provides a kind of using...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01B11/24G06T7/70

CPCG01B11/24G06T7/70Y02E30/30

Inventor 单意志秦亚林余世安黄健钱伏华

Owner CHINA NUCLEAR IND HUAXING CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com