Checking method for location degree and geometric dimension of surface complex structure

A technology with geometric dimensions and complex structures, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of high labor intensity for inspectors, errors and omissions, general measuring tools, etc., to achieve economic benefits, high efficiency, fast and easy operation , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution will be described in further detail below.

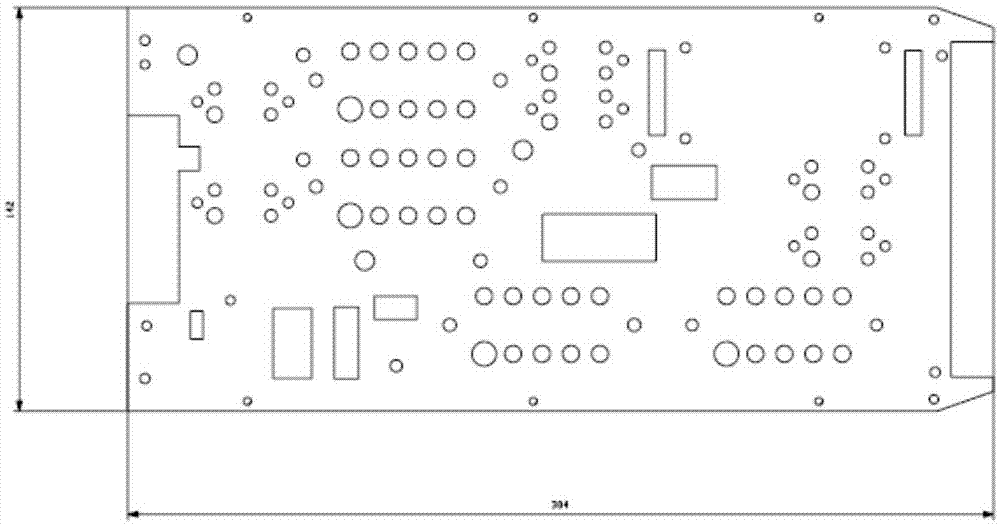

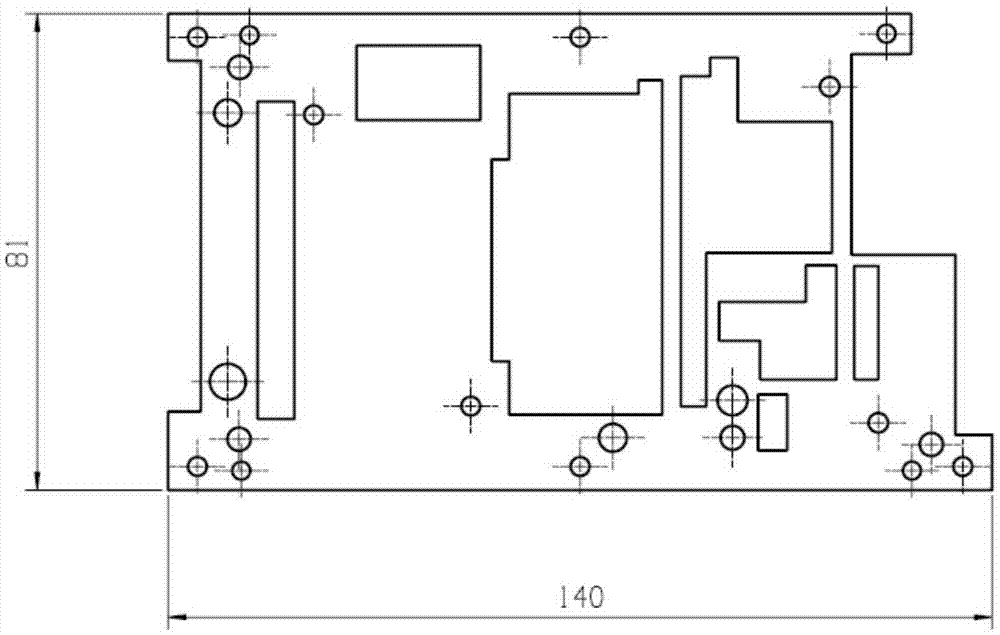

[0018] In the method described in the technical solution, by drawing the planar structure to be detected on a transparent film at a ratio of 1:1, and then covering the transparent film on the surface structure to be detected, it is judged whether the detected structure meets the design requirements. When completing this method, the following steps are generally adopted. Step 1, draw the design pattern on the transparent film at a ratio of 1:1; Step 2, measure whether the geometric elements of the pattern drawn on the film meet the design requirements; The required transparent film pattern is covered on the surface of the object to be inspected for comparison, and it is judged whether the geometric elements of the object to be inspected meet the design requirements. In this implementation step, before testing the surface structure to be tested, it is first checked whether the geometric elements of the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com