State monitoring and fault diagnosis method for large-scale semiconductor manufacture process

A technology for manufacturing process and fault diagnosis, applied in the direction of semiconductor/solid state device testing/measurement, etc., can solve the problem of not implementing process variable data set redundant information elimination, inability to effectively detect nonlinearity and multimodality, and inability to local variance information. Carry out effective extraction and other problems to achieve the effect of improving engineering applicability, avoiding difficult collection, and improving product quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

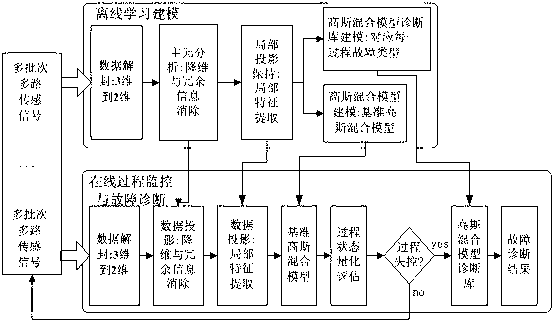

[0018] Such as figure 1 As shown, the state monitoring and fault diagnosis method of this large-scale semiconductor manufacturing process, the specific operation steps are as follows:

[0019] 1. Arrange relevant sensors at key positions in the semiconductor manufacturing process to pick up various signals that can reflect the performance status of the semiconductor manufacturing process (such as gas flow pressure during wafer etching, RF power supply size, RF resistance, voltage, etc.), and the signals pass through the data The filter circuit and amplifier circuit on the acquisition card perform data acquisition, and the data acquisition card also converts the analog signal into a digital signal, and the data collected by the data acquisition card is transmitted to the computing terminal through the network for further data analysis and processing. Assume that the number of all sensors on the production line is , the acquisition time duration of each sensor signal in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com