Method for checking position of prefabricated steel component based on three-dimensional scanner technology

An inspection method and technology for prefabricated components, which are applied to instruments, measuring devices, measuring instruments, etc., can solve the problems of inspection accuracy and progress impact, large calculation work, labor and time-consuming, etc., to meet the needs of quality control, flexible inspection, and effective results. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

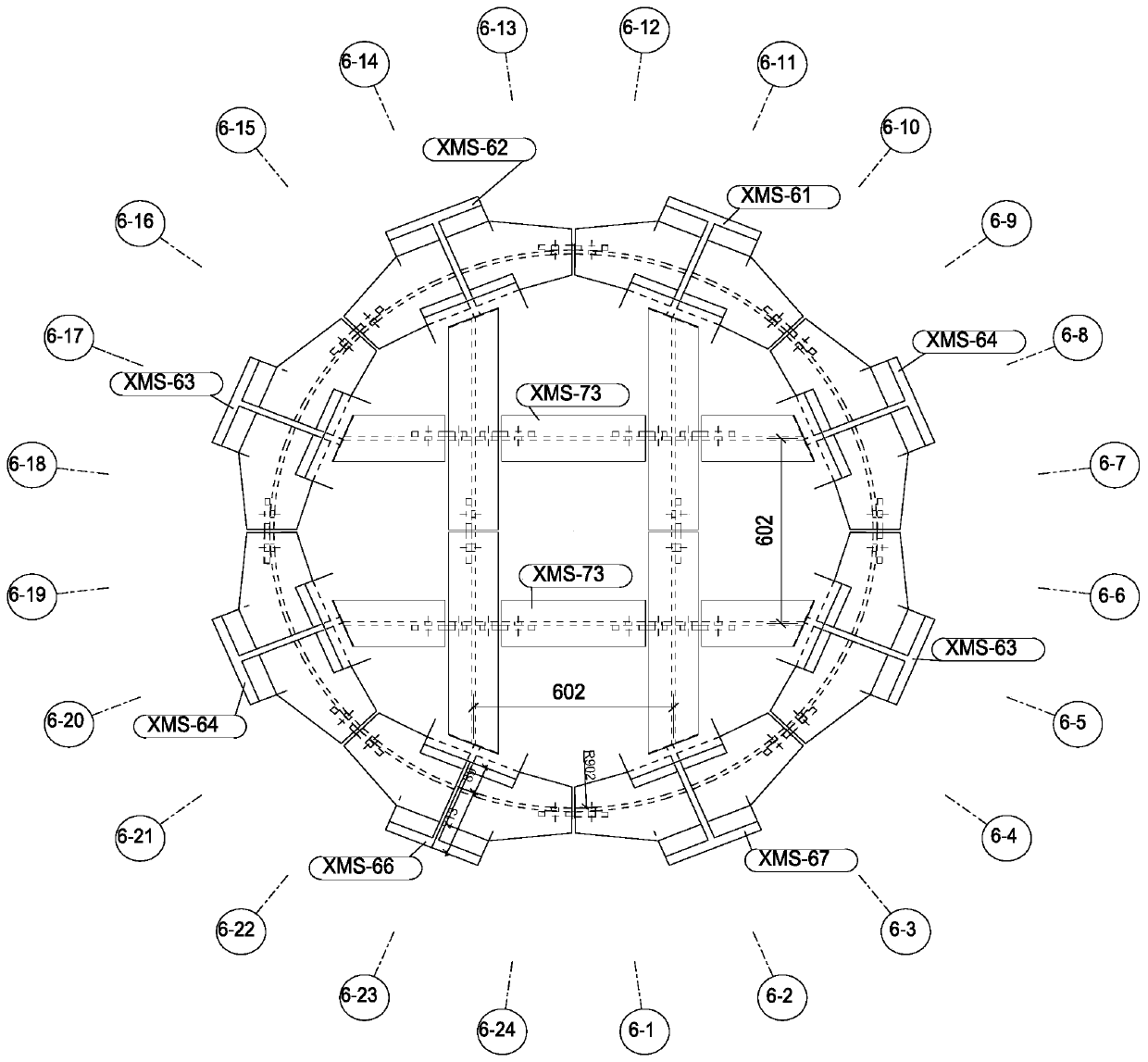

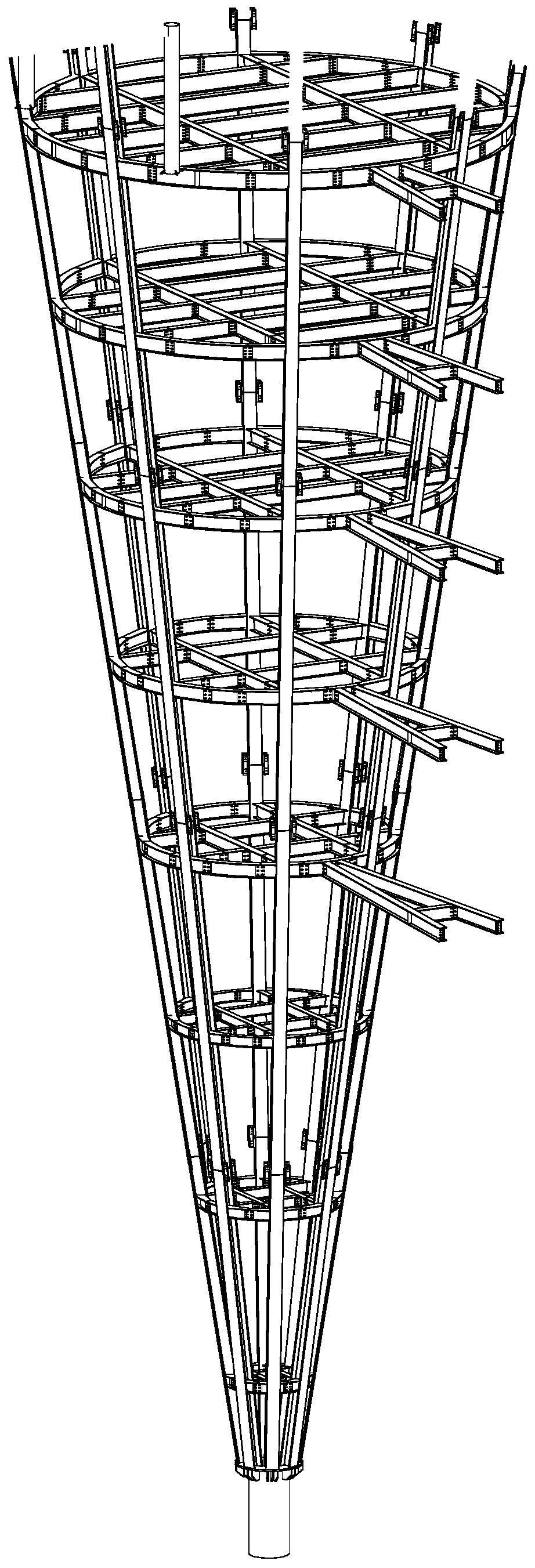

[0043] In this example, the second phase of the Zhejiang Buddhist Academy (Maitreya Shrine) project, the first section of the inverted cone pillar Tiangong of Mount Xumi, is composed of 8 inclined columns, and the vertical surface is inclined outward by 6.4° through the center of the circle. The vertical and horizontal legs are spliced into a whole, the length is 10306, the bottom elevation is 2.850m, and the coordinates of the center of the circle are set to (0, 0).

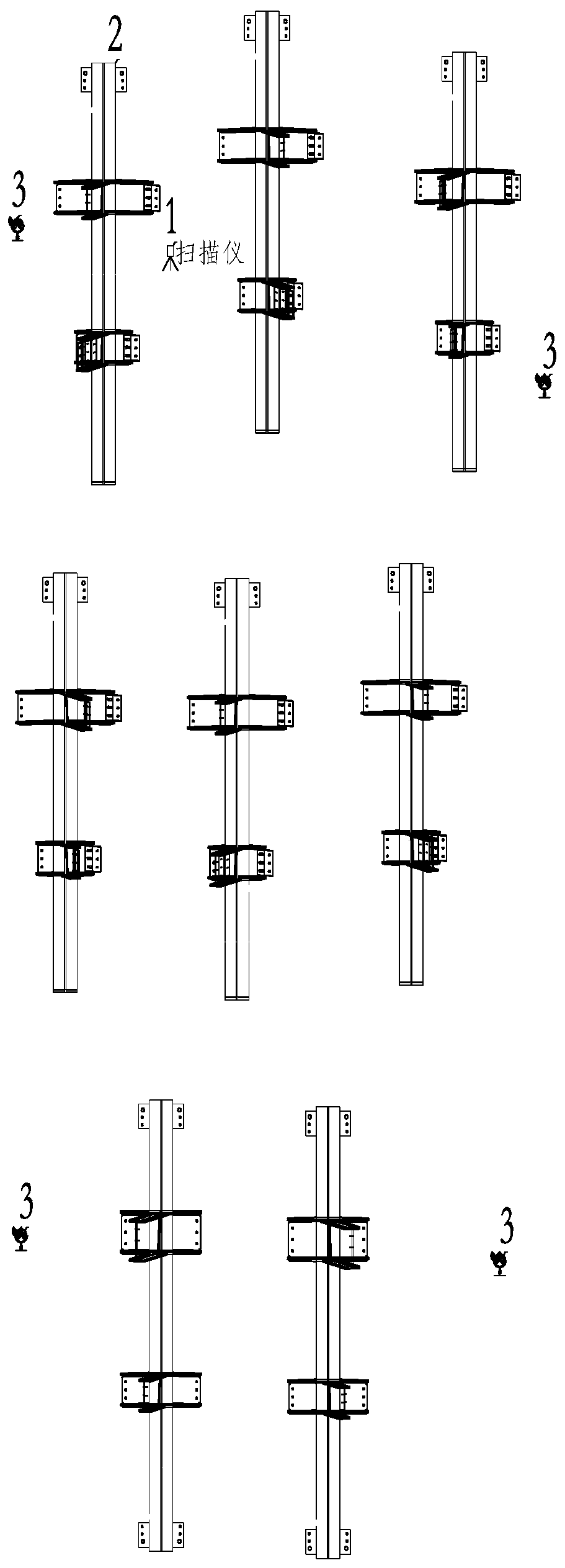

[0044] Application scanner inspection method see Figure 1 to Figure 7 , including the following steps:

[0045] The first step, placing - the prefabricated steel components are placed on the floor of the workshop;

[0046] The second step, target - according to the component placement area, set no less than three target points, and the target position forms a triangle;

[0047] The third step, scanning - use a scanner to scan the prefabricated steel components to obtain scanned images of each prefabricated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com