Method and device for detecting and controlling quality of rigid production line in Ethernet bus mode

A production line and Ethernet technology, applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems of affecting processing quality, affecting processing, and high correlation of processing quality, so as to achieve stable product quality, reduce defective products, The effect of strong robustness and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0024] Example. A method for quality inspection and control of a rigid production line in Ethernet bus mode, characterized in that: the method includes:

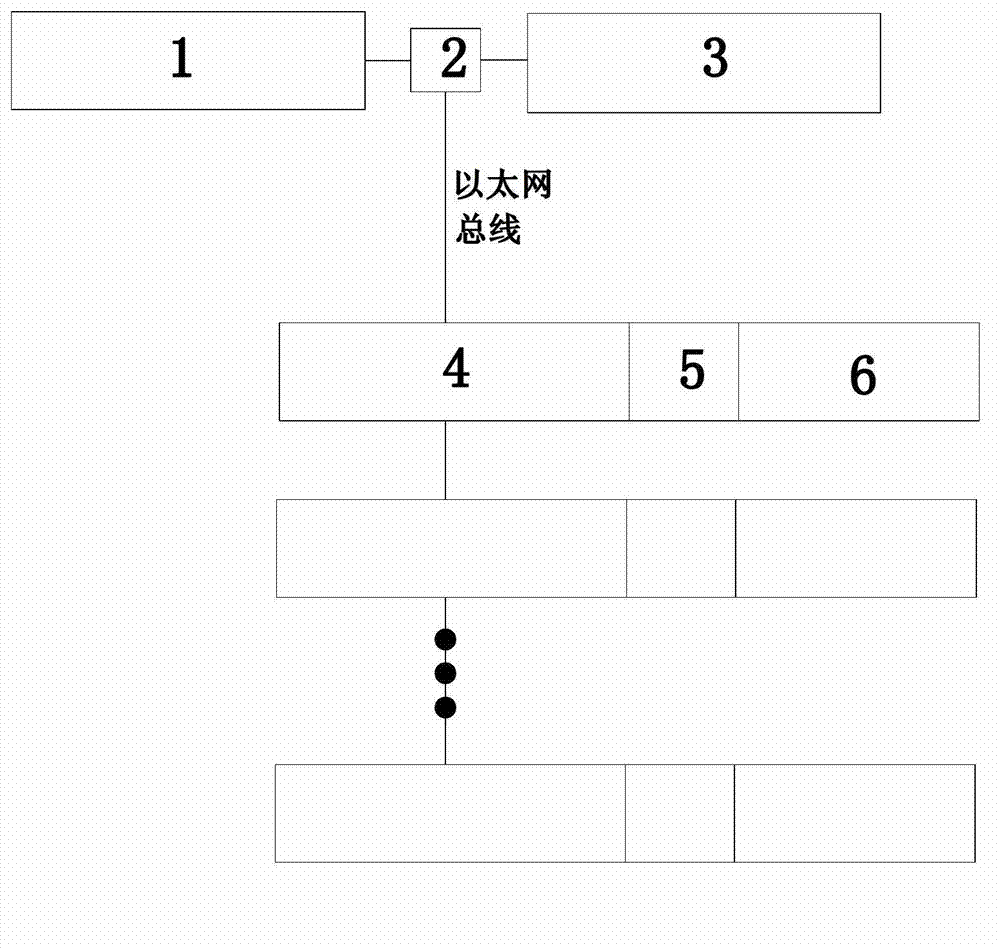

[0025] Process each corresponding station through several processing equipment and collect station information through the controller;

[0026] The station information collected above is transmitted to the main control computer through the Ethernet transfer module and the remote access module;

[0027] The main control computer provides product quality trend status information through the quality analysis module according to the collected station information;

[0028] Finally, according to the product quality trend state information, the processing equipment is fed back through the controller.

[0029] The processing equipment includes a millin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com