Flow cytometry fluorescent microsphere quality control product and preparation method thereof

A flow cytometer and fluorescent microsphere technology, which is applied in the field of flow cytometer fluorescent microsphere quality control products and their preparation, can solve the problems of not being able to meet the detection of multiple channels at the same time, harsh reaction conditions, dye quenching, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

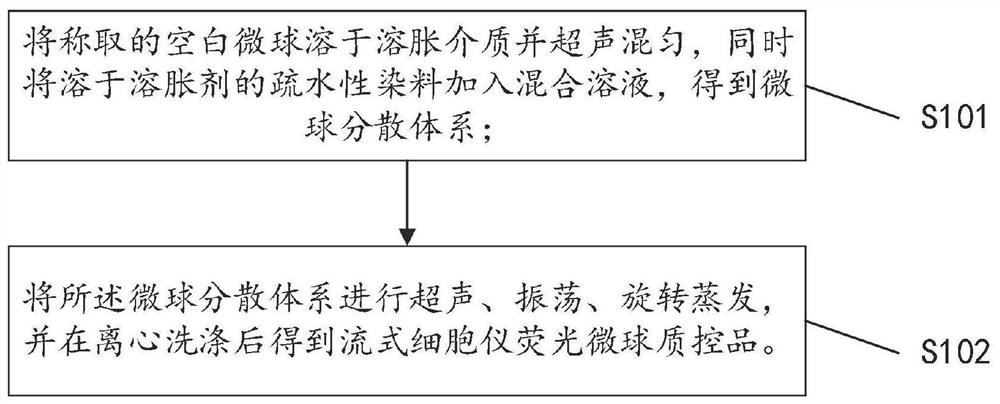

[0030] see figure 1 , the invention provides a method for preparing a flow cytometer fluorescent microsphere quality control product, comprising the following steps:

[0031] S101. Dissolving the weighed blank microspheres in the swelling medium and ultrasonically mixing, meanwhile, adding the hydrophobic dye dissolved in the swelling agent into the mixed solution to obtain a microsphere dispersion system.

[0032] Specifically, weigh 0.3 g to 1 g of blank microspheres with a coefficient of variation of forward scattered light less than 3%, and dissolve the blank microspheres in a swelling medium with a mass fraction of 1 to 5%, and use an ultrasonic intensity of 50 %~100% sonication for 1min~5min to obtain a mixed solution; weigh 2mg~10mg of hydrophobic dye and dissolve it in 20mL~50mL of swelling agent, add the mixed solution to obtain a microsphere dispersion system, The microspheres are polystyrene microspheres, the particle size should be suitable for flow cytometry, pre...

Embodiment 1

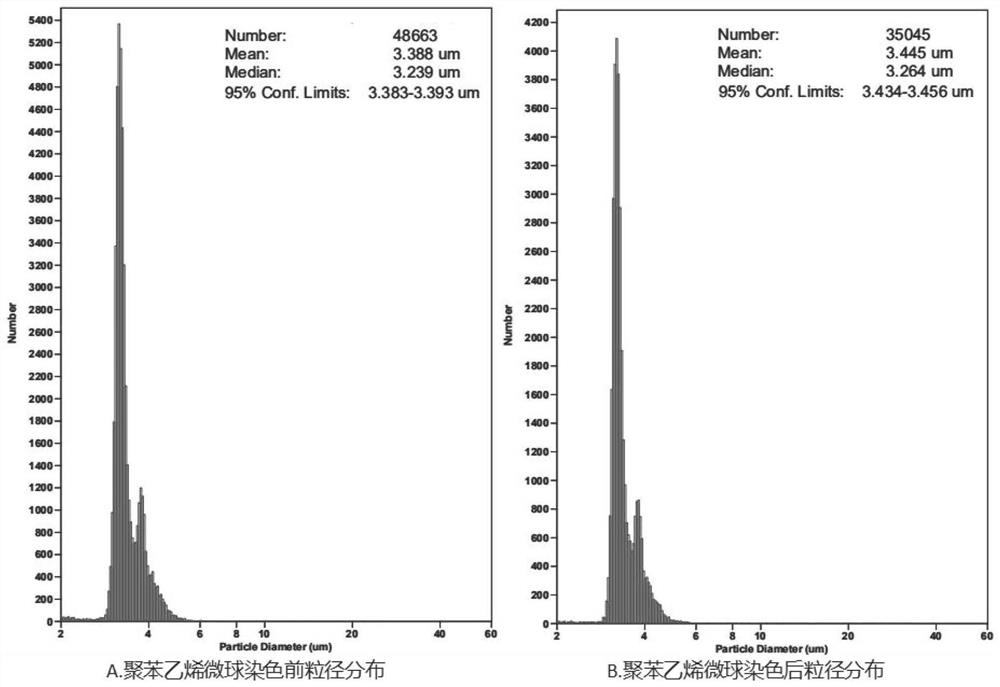

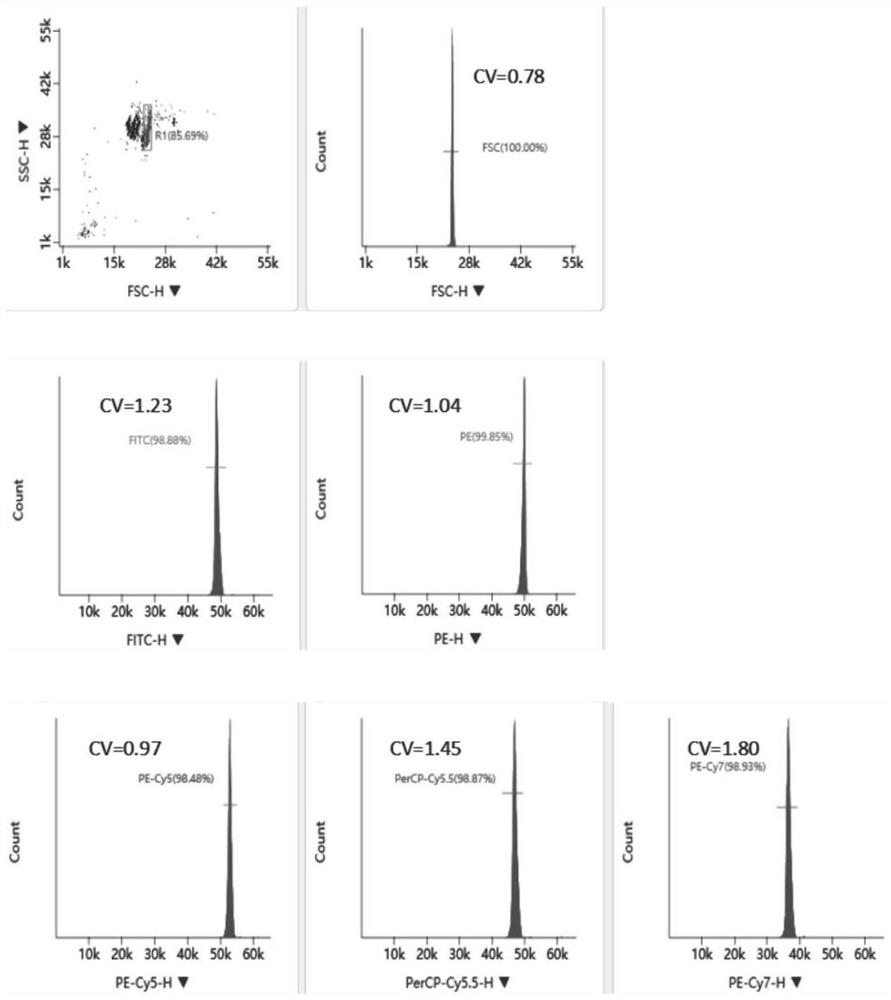

[0039]Weigh 0.3 g of blank microspheres with a particle size of 3.39 μm and a coefficient of variation of forward scattered light of 0.73%, dissolve them in 100 mL of Pluromic F127 aqueous solution (1% by mass fraction), and ultrasonically disperse them uniformly for 1 min (intensity is set to 50%) Weigh 2 mg of Nile Red dye and dissolve it in 20 mL of tetrahydrofuran, mix the two, ultrasonicate for 2 min (intensity is set to 100%), and vibrate on a constant temperature shaker for 30 min (room temperature is 21.3 °C, speed is 100 r / min), After the oscillation is completed, transfer to a rotary evaporator for rotary evaporation (temperature is set to 30°C, rotation speed is 60r / min, pressure is 0.05MPa, time is 10min), and the product after rotary evaporation is centrifuged (relative centrifugal force is 3000g, time is 2min) And washed repeatedly with ethanol until the supernatant was colorless. The supernatant was discarded, and the fluorescent microspheres were dispersed and ...

Embodiment 2

[0042] Weigh 0.5 g of blank microspheres with a particle size of 3.39 μm and a coefficient of variation of forward scattered light of 0.73%, dissolve them in 150 mL of Pluromic F127 aqueous solution (1% by mass fraction), and ultrasonically disperse them uniformly for 2 min (intensity is set to 50%) ; Dissolve 3.5mg of Nile Red dye in 35mL of tetrahydrofuran, mix the two, ultrasonicate for 3 minutes (intensity is set to 100%), shake on a constant temperature shaker for 40 minutes (room temperature is 22.8°C, speed is 120r / min) After the oscillation is completed, transfer to a rotary evaporator for rotary evaporation (the temperature is set to 37°C, the rotating speed is 60r / min, the pressure is 0.07MPa, and the time is 20min), and the product after the rotary evaporation is centrifuged (the relative centrifugal force is 3000g, and the time is 3min ) and washed repeatedly with ethanol until the supernatant was colorless. The supernatant was discarded, and the fluorescent micros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com