Tobacco leaf subsection threshing and redrying method

A technology of threshing and re-baking and tobacco leaves, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment, which can solve problems such as no known solutions, improve use value and comprehensive utilization benefits, solve the bottleneck of raw material shortage, and promote development Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The 2007 Yunnan Songming Yunyan 87B2F tobacco leaf was used as the test material.

[0032] 1. Establish the cutting plan, see Table 1 for details.

[0033] Table 1 Three-stage splitting scheme for threshing and re-cured tobacco leaves

[0034]

[0035] 2. Threshing and redrying plan

[0036] For different parts and grades of tobacco leaves, according to the quality status of the leaf tip, leaf middle, and leaf base, that is, the processing characteristics, the corresponding threshing and redrying schemes are formulated respectively.

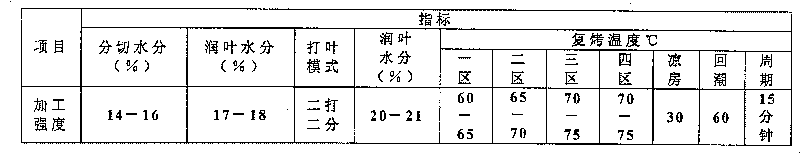

[0037] 1) Upper premium tobacco leaves:

[0038] According to the quality state and mechanical processing performance of the tip of the upper premium tobacco leaf, the re-roasting and threshing processing intensity of the leaf tip is designed as light threshing and moderate repeated roasting. The main purpose is to reduce the negative effect of high nicotine at the leaf tip And removal of dead scorch miscellaneous gas (such as dry th...

Embodiment 2

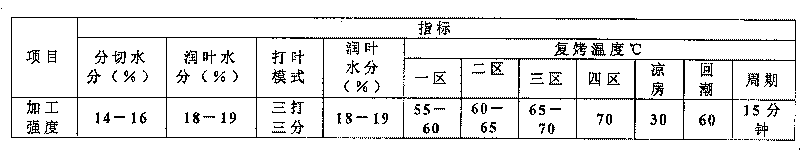

[0098] Example 1 was repeated, with the following differences: the 2007 Yunnan Songming Yunyan 87C 3F tobacco leaf was used as the test material.

Embodiment 3

[0100] Example 1 was repeated, with the following differences: the 2007 Yunnan Songming Yunyan 87X 2F tobacco leaf was used as the test material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com