Truss crane track inspection method based on three-dimensional scanner technology

An inspection method and scanner technology, applied to instruments, measuring devices, optical devices, etc., can solve problems such as inability to ensure work quality, long time spent, and difficulty in ensuring safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

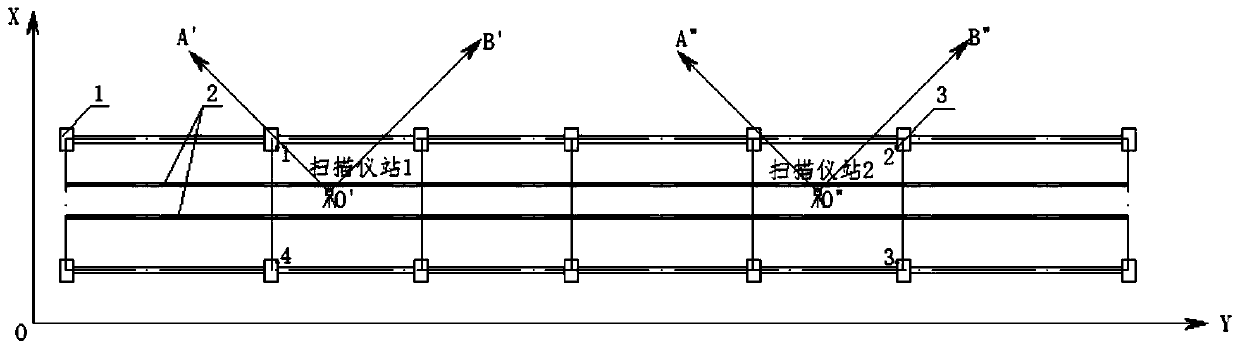

[0047] This embodiment provides a method for checking the position of a truss hanging based on the HDS7000 three-dimensional scanner technology, such as figure 1 and figure 2 As shown, the origin of the construction coordinate system is the intersection of the ground and the two side walls (columns) parallel to the ground, the X axis is a line parallel to the ground and the wall, the Y axis is perpendicular to the X axis on the ground, and the Z axis is upward, in line with Right-handed coordinate system, the plane formed by the A-axis and B-axis of the scanner coordinate system is parallel to the ground, and the H-axis is upward, which also conforms to the right-handed coordinate system. , the detection method includes the following steps:

[0048] The first step is to select three or more control datum points on the cylinder, set black and white target marks at the same time, and measure the coordinates of the control datum points in the construction coordinate system;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com