Non-fixed measuring station truss vehicle track position checking method

A technology of track position and inspection method, which is applied in the direction of measuring devices, measuring instruments, surveying and navigation, etc., can solve problems such as complicated operation, and achieve the effects of simple operation, avoidance of occupation, and flexible and convenient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

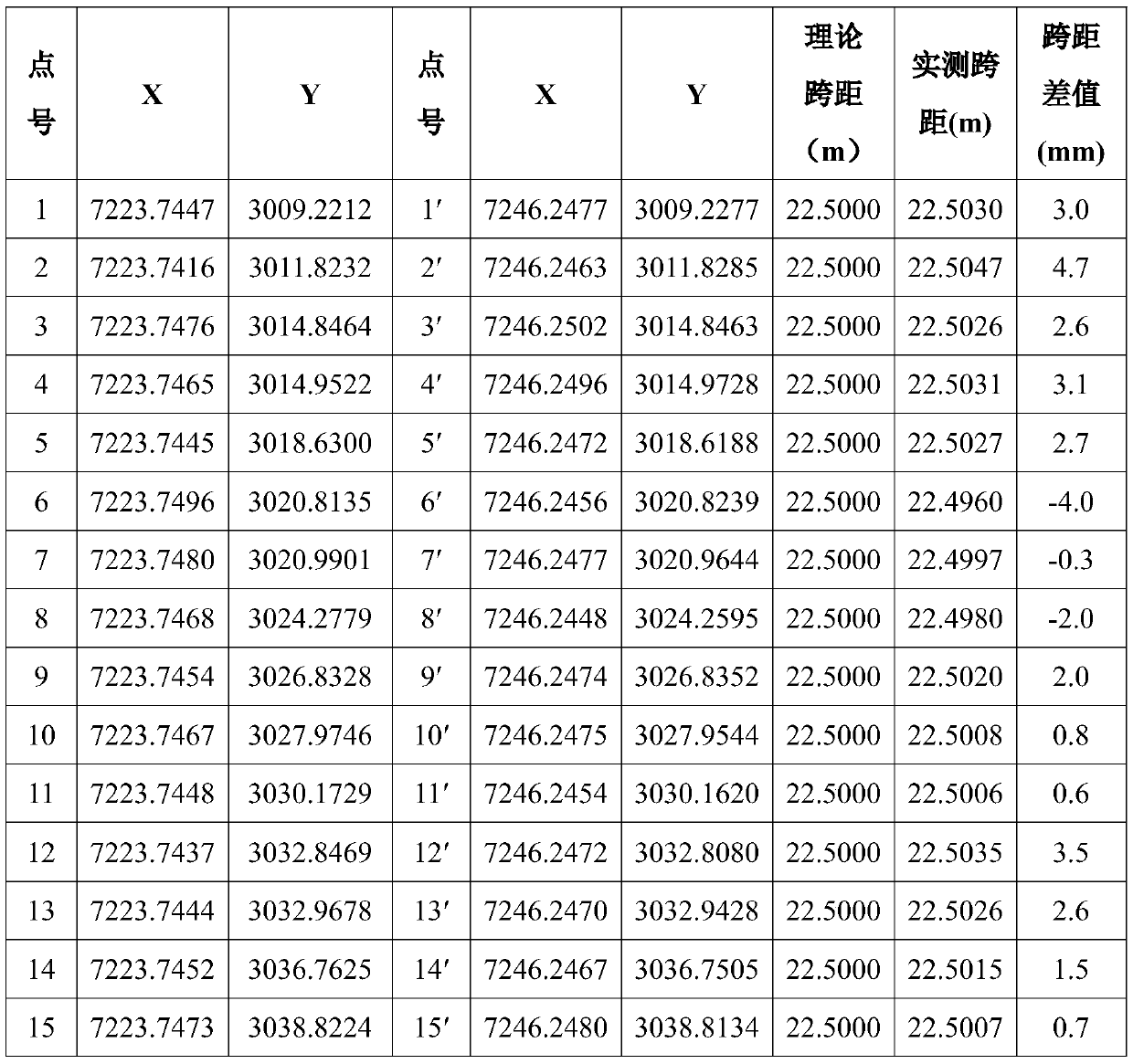

[0041] The length of the crane track in the first-phase machine repair workshop of a nuclear power plant is 102m, the span is 22.50m, and the track is installed on the crane beam with an elevation of +7.100m.

[0042] see Figure 1-2 , the present invention applies a kind of non-fixed measuring station method track position checking method, comprises the following steps:

[0043] Step 1: Set up the total station station, set up the total station at the ground position in the middle of the truss car track, and be able to see the positions of each detection point;

[0044] Step 2: track start point and end point measurement, measure the coordinates of the track start point and end point on one side. In this embodiment, the coordinates of the start point 2 are (7166.2459, 3014.4692), and the coordinates of the end point 3 are (7261.8414, 3051.4523);

[0045] Step 3: Calculate the azimuth angle. Calculate the azimuth angle of the starting point and the ending point according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com