Light source alternate strobe synchronous camera shooting method and vision detection system

A synchronous camera, alternating stroboscopic technology, applied in the parts of the TV system, optical test defects/defects, TV and other directions, can solve the problems of limited accessibility, insufficient weld tracking, misjudgment, etc., to avoid information exchange. Interfere, facilitate image processing, and satisfy the effect of quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

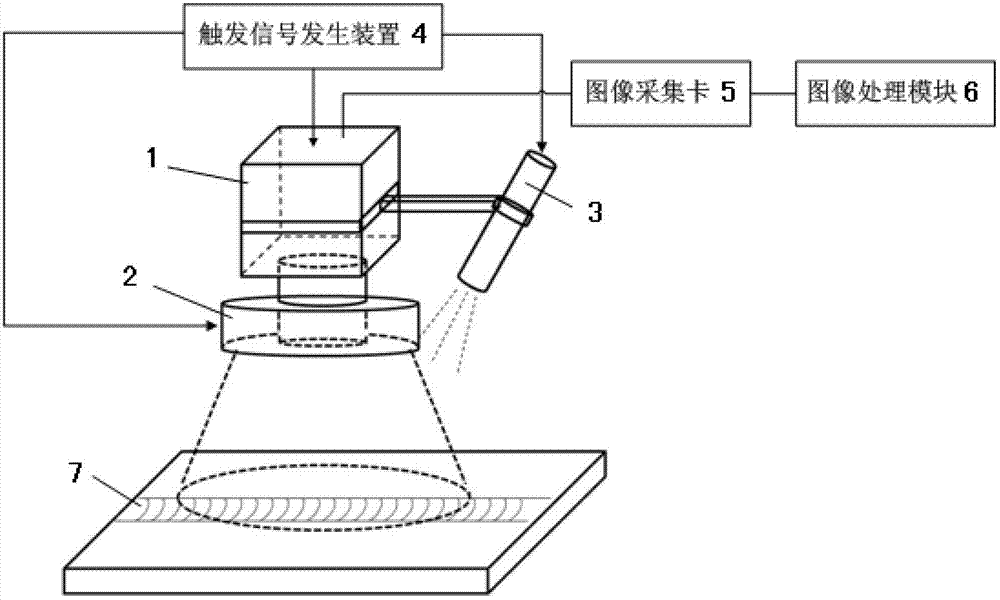

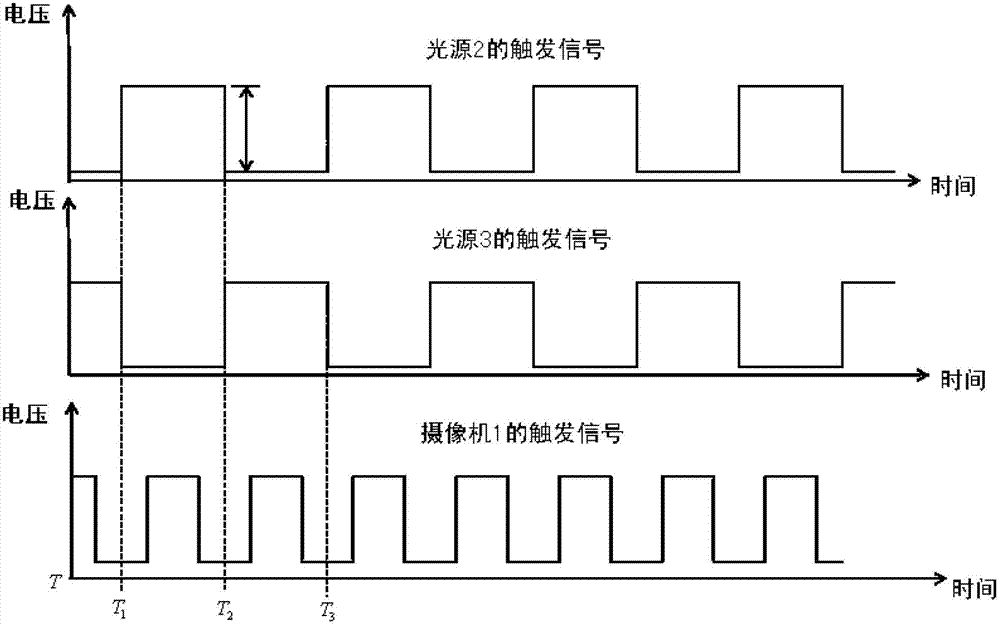

[0020] Such as figure 1 As shown, the visual inspection system of the present invention includes a camera 1 , an annular surface light source 2 , a multi-line laser structured light source 3 , a trigger signal generator 4 , an image acquisition card 5 and an image processing module 6 . A narrow-band filter (not shown in the figure) is set on the front end of the camera 1 lens. The surface light source 2 is fixed directly below the camera 1 through a peripheral bracket, and the multi-line laser structure light source 3 is fixed and set on the On the camera 1 side, the light plane of the multi-line laser structured light source 3 is at 45° to the optical axis of the camera 1 lens. The output end of the trigger signal generating device 4 is respectively connected with the trigger interface of the camera 1, the surface light source 2 and the multi-line laser structure light source 3 to control it to work, the output end of the camera 1 is connected to the input end of the image ac...

Embodiment 2

[0035] This embodiment takes the defect on the surface of the weld as the object to be tested as a specific embodiment to further illustrate the process of the light source alternate strobe and synchronous camera method. This embodiment has the same structure as the visual inspection system adopted in Embodiment 1. The visual inspection system is used for visual inspection after welding is completed.

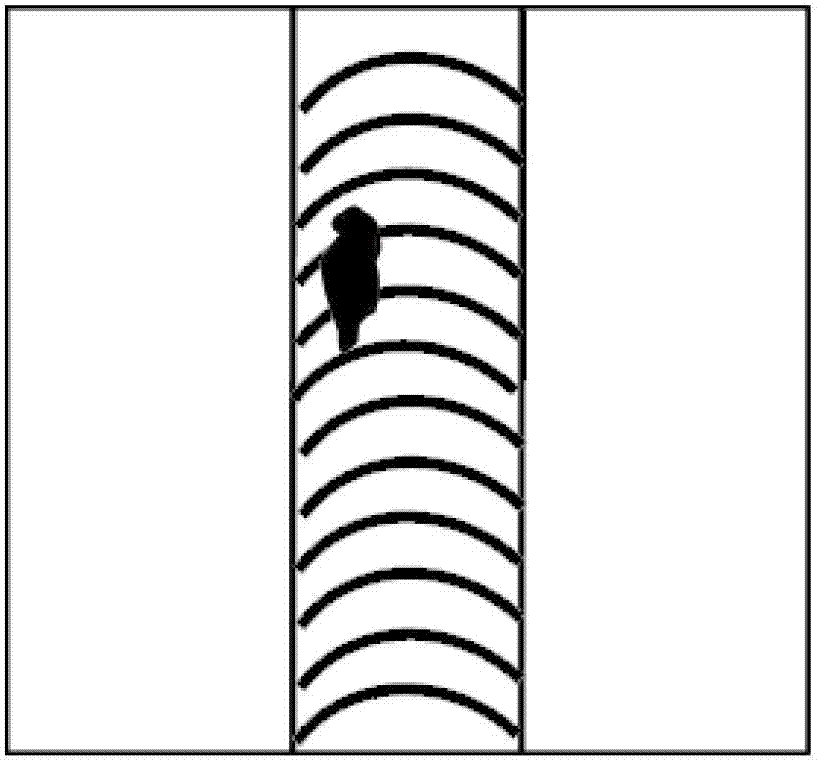

[0036] Such as figure 2 , as shown in Figure 3, during detection, the LED monochromatic surface light source 2 is irradiated vertically on the surface of the weld, and the laser structured light source 3 is obliquely projected on the surface of the weld, and the direction of the linear light strip formed on the surface of the weld is perpendicular to the direction of the weld , using the light source alternate strobe synchronous imaging method of the above-mentioned embodiment 1 to capture the image of the weld surface defect, the process is: (such as figure 2 As shown) the t...

Embodiment 3

[0040] The structure of the visual detection system of this embodiment and embodiment 1 and embodiment 2 is basically the same, the difference is: two light sources 2,3 are respectively fixed on the both sides of CCD digital camera 1 by peripheral brackets, each light source The included angle between the normal direction of the light-emitting surface and the axis of the CCD digital camera 1 is 20-40 degrees. Before taking pictures, the CCD digital camera 1 axis is directly facing the metal groove 8. When taking pictures, the axis of the CCD digital camera 1 is perpendicular to the surface of the area to be measured.

[0041] Such as Figure 4 As shown, the present embodiment takes the high-reflectivity metal groove 8 as the object to be measured as a specific embodiment to illustrate the process of the light source alternate stroboscopic synchronous imaging method again, and adopts the light source alternate stroboscopic synchronous imaging method of the above-mentioned embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com