Method for detecting succinylation modified gelatin and combination succinic acid in its injection

A technology of succinylation and succinic acid, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of hydrolysis operation time, long separation and detection time, affecting the service life of C18 chromatographic column, and not specifying the control index of acylation degree , to achieve the effect of shortening the separation and detection time, good application prospects, and solving quality control problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1: the selection test of inorganic acid removal method in the hydrolyzate

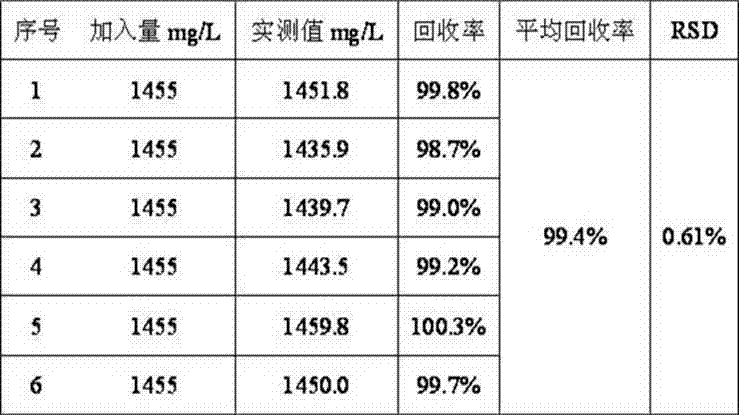

[0012] The recovery rate of the reference substance of succinic acid was used as the investigation index of the method selection test for the removal of inorganic acids in the hydrolyzed solution. Take an appropriate amount of succinic acid reference substance, add appropriate amount of concentrated hydrochloric acid and water, simulate the hydrolysis solution of the reference substance, and accurately measure 2ml, use water bath evaporation method and gas drying method to remove inorganic acid respectively, then wash with water and dilute to 10ml , followed by treatment with a 0.45 μm microporous filter, ODS extraction column, and SP extraction column, respectively injected into an ion chromatograph, separated and determined the content of succinic acid, and investigated the recovery rate of succinic acid. The suitable separation and determination conditions are: ion chromatography (...

Embodiment 2

[0014] Embodiment 2: Selection test of microwave hydrolysis temperature

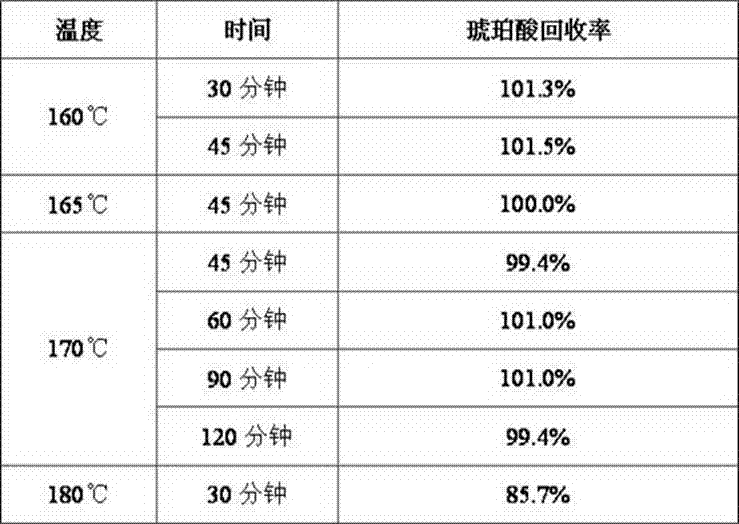

[0015] The recovery rate of the succinic acid reference substance was used as the investigation index of the microwave hydrolysis temperature selection test. Precisely measure 1ml of the aqueous solution of succinic acid reference substance, put it in a microwave digestion tube, add 5ml of concentrated hydrochloric acid, carry out microwave hydrolysis at different temperatures and times, dry it with air at 70°C to remove the inorganic acid and treat it, inject it into an ion chromatograph for separation and determination, Investigate the recovery rate of succinic acid. Results (see Table 2): Succinic acid is stable when it is hydrolyzed by microwave at or below 170°C, and the recovery rate decreases when it is above 180°C. Therefore, this patent selects microwave hydrolyzed succinylated modified gelatin and its injection solution at a temperature of 170°C.

[0016] Table 2, the result table of microwav...

Embodiment 3

[0018] Embodiment 3: the selection test of microwave hydrolysis time

[0019] Precisely measure 1ml of succinylated gelatin injection, put it into a microwave digestion tube, add 5ml of concentrated hydrochloric acid, hydrolyze at 170°C for 15, 30, 45, 60, 90, and 120 minutes respectively, transfer each hydrolyzate and dilute to 25ml with a glass of water. Precisely measure 2ml, air-dry at 70°C to remove inorganic acid, wash with water and dilute to 10ml, treat with 0.45μm microporous filter, ODS extraction column, SP extraction column successively, and determine the content of succinic acid by ion chromatography. The experimental results (see Table 3) show that the bound succinic acid in the succinylated gelatin injection can be completely hydrolyzed by hydrolysis at 170°C for 60 minutes.

[0020] Microwave hydrolysis conditions Succinic acid content (mg / L) 170°C for 15 minutes 830.3 170°C for 30 minutes 832.2 170°C for 45 minutes 964.3 170°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com