High-strength permeable fiber concrete and preparation method thereof

A technology of permeable concrete and high-strength fiber, which is applied in the field of road paving materials and high-strength fiber permeable concrete. It can solve the problems of expansion cracking and permeable concrete not being able to adapt to the temperature, so as to ensure durability, improve freeze-thaw resistance, and improve project quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

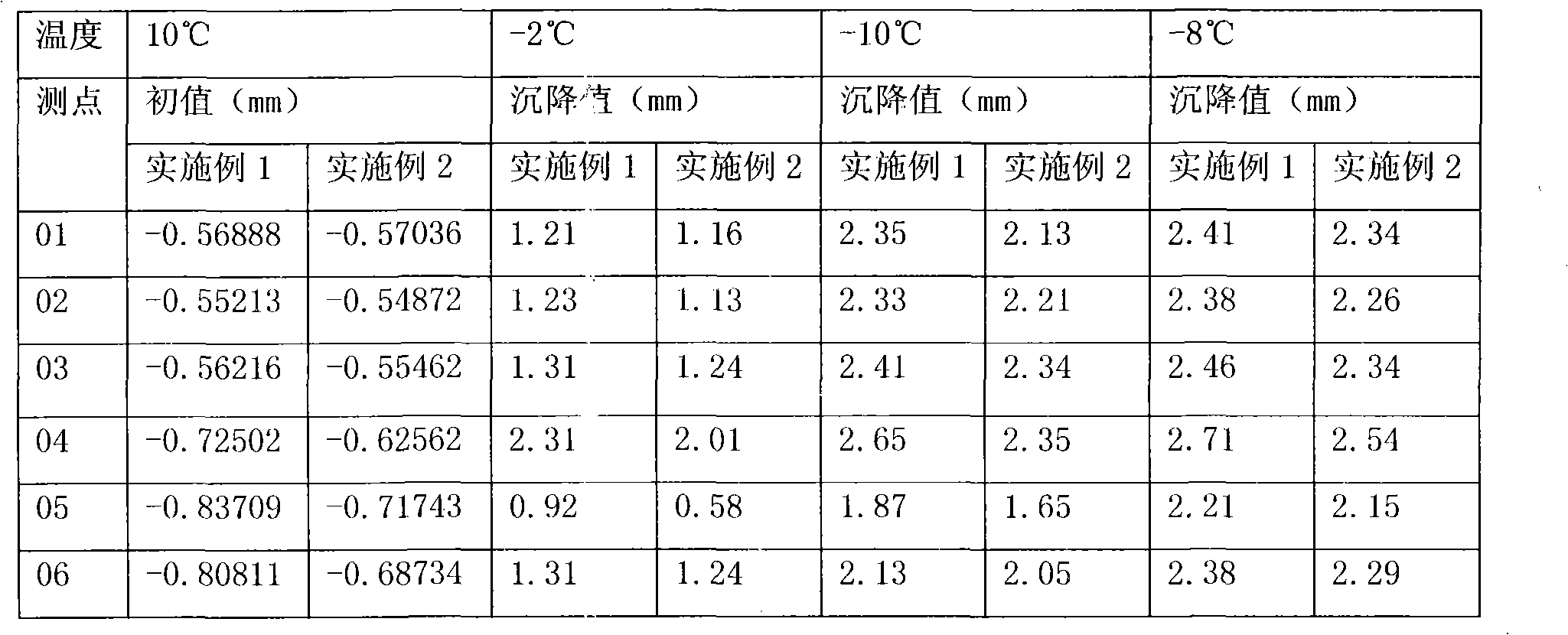

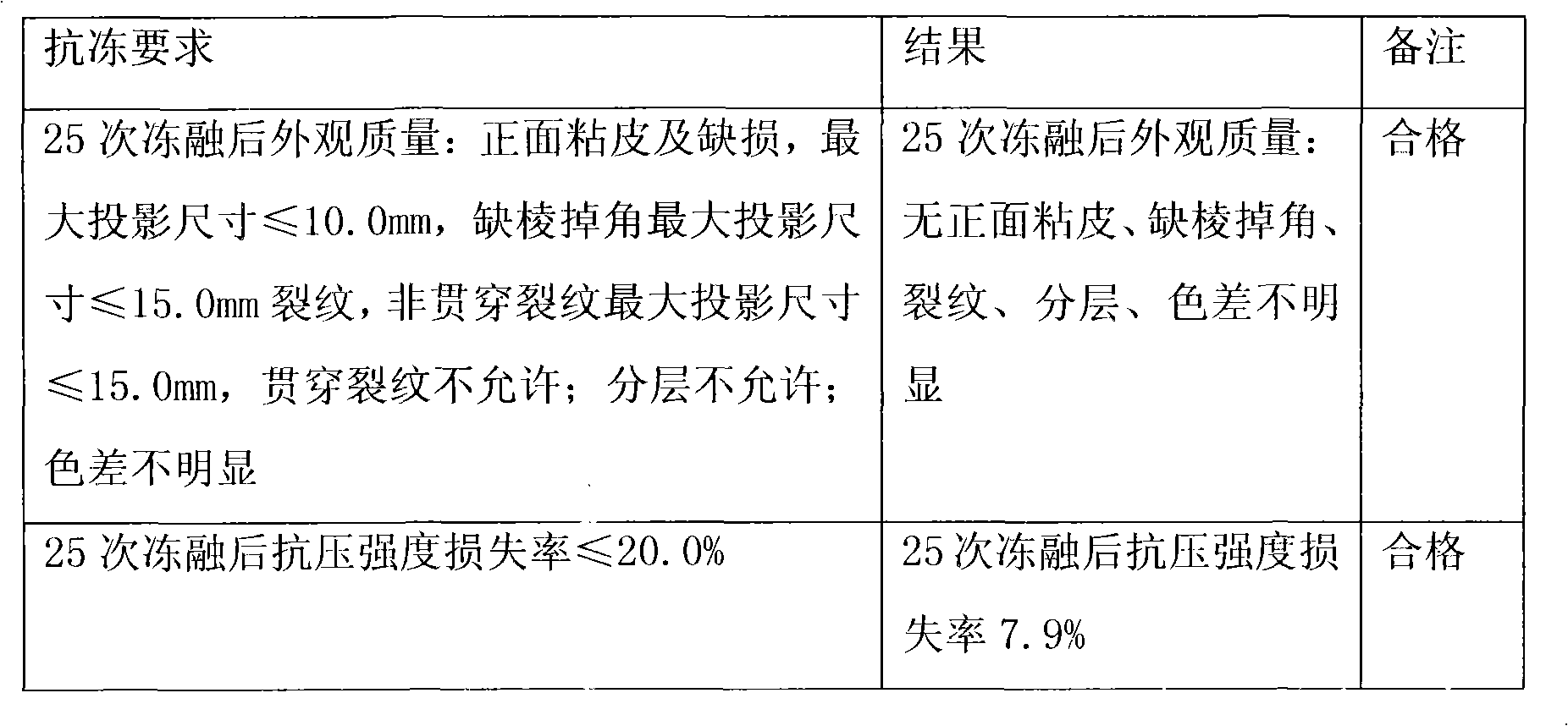

Embodiment 1

[0032] A kind of high-strength fiber permeable concrete, including cement, admixture, water, stone and high-strength engineering fiber, wherein the proportioning of each raw material (by mass Kg / cubic):

[0033] High-strength fiber: cement: gravel: admixture: water = 15:410:1520:10:120.

Embodiment 2

[0035] A kind of high-strength fiber permeable concrete, comprising cement, admixture, water, stone, high-strength engineering fiber and grinding aid, wherein the proportioning of each raw material (by mass Kg / cubic):

[0036] High-strength fiber: grinding aid: cement: gravel: admixture: water=15:1.5:410:1520:10:120.

[0037] The actual preparation steps of above-mentioned embodiment concrete are:

[0038] 1. Stir

[0039] High-strength fiber permeable concrete cannot be mixed manually, and ordinary concrete mixing machines are used for mixing. When mixing, the materials are put into the mixer according to the specified ratio of materials and the order of feeding, and the specified amount of water is added 2 to 3 times to continue stirring for about 1.5 to 2 minutes. . Depending on the uniformity of the stirring, the time of mechanical stirring can be extended appropriately, but it is not suitable to stir for too long.

[0040] 2. Paving and casting

[0041] The pouring is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com