Brand new pervious pavement total-pervious leveling layer material and total-pervious pavement structure

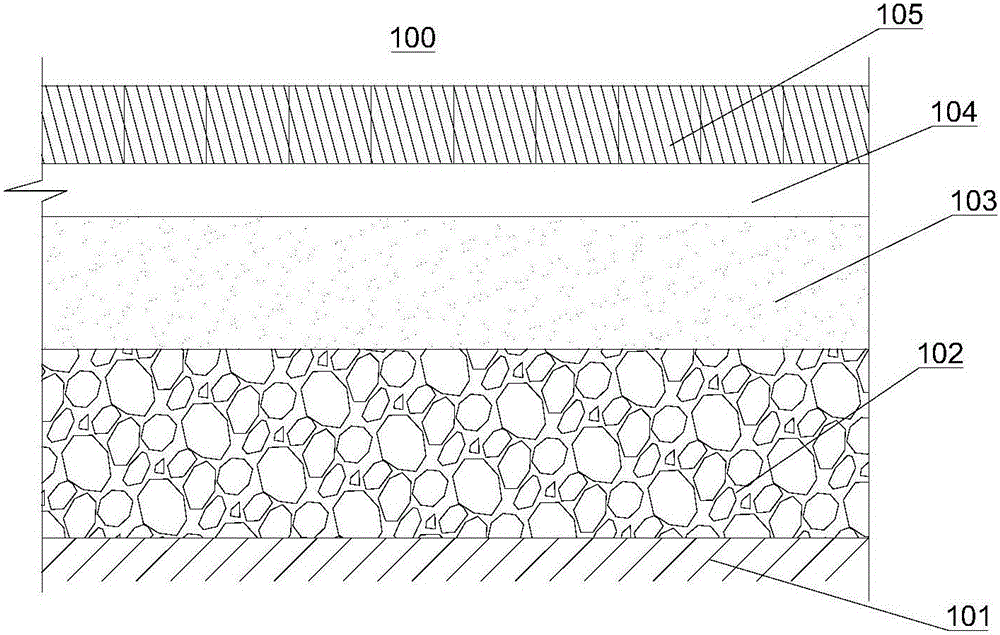

A technology of permeable pavement and leveling layer, which is applied in municipal engineering and construction fields, can solve the problems of poor water permeability and low bonding strength of leveling layer, and achieve the effect of good water permeability, high compressive strength and large compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

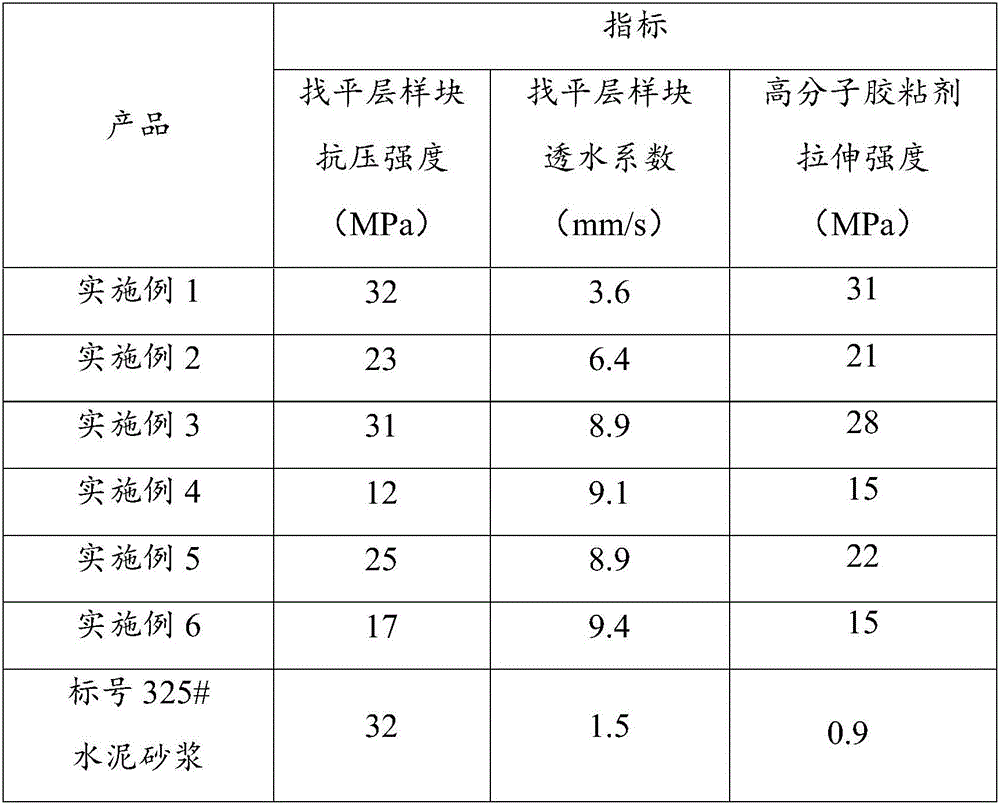

Embodiment 1

[0032] A water-permeable pavement leveling layer material, comprising 80 grams of epoxy resin, 5000 grams of fine gravel stone particles with a particle size of 0.5-10mm discontinuously graded and 20% of coarse sand. The permeable pavement leveling layer material is formed by curing epoxy resin, gravel stone fine particles and coarse sand. The grade of epoxy resin is E51, the viscosity at 25°C is 12000mPa·s, and the epoxy value is .51.

Embodiment 2

[0034] A water-permeable pavement leveling layer material comprises 102 grams of acrylic resin and 1700 grams of fine gravel stone particles with a particle size of 1-12 mm. The permeable pavement leveling layer material is formed by mixing and curing acrylic resin and gravel stone fine particles. The grade of acrylic resin is 1321, and the viscosity at 25°C is 5Pa·s.

Embodiment 3

[0036] A water-permeable pavement leveling layer material comprises 150 grams of polyurethane resin and 7,500 grams of fine gravel stone particles with a particle size of 15 mm. The permeable pavement leveling layer material is formed by mixing and curing polyurethane resin and gravel stone fine particles. The polyurethane resin is selected from the two-component polyurethane resin disclosed in Chinese patent CN 104004490 B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com