Self-compacting bituminous concrete waterproof seal and construction method thereof

An asphalt concrete and sealing layer technology is applied in the field of self-compacting asphalt concrete waterproof sealing layer and its construction, which can solve the problems of difficult construction, difficult to repair, poor waterproofness and durability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

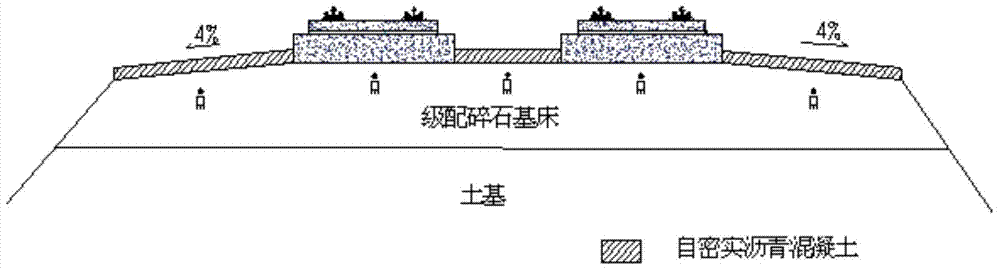

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] Such as figure 1 The position of the waterproof sealing layer of the present invention is between the lines of the railway subgrade and the road shoulder, and is particularly suitable for high-speed railway subgrades in alpine regions.

[0034] The invention discloses a self-compacting asphalt concrete waterproof sealing layer, which is characterized in that the waterproof sealing layer is located between the surface lines of the high-speed railway subgrade and at the road shoulder, and includes asphalt binder, warm-mix compacting agent, aggregates and fillers.

[0035] Preferably, the thickness of the waterproof sealing layer is 35-100 mm.

[0036] The waterproof sealing layer is preferred, and the bond strength and shear strength with the track slab base are not less than 0.2MPa.

[0037] The preferred asphalt binder is modified asphalt with performance grad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com