Machine-made inorganic silicon-magnesium external wall thermal insulation composite board through one-step molding and production technology thereof

A thermal insulation composite board and external wall thermal insulation technology, which is applied to ceramic molding machines, thermal insulation, manufacturing tools, etc., can solve the problems of poor impact strength, poor surface flatness, and difficult quality assurance management, etc., to achieve good flatness and production The effect of fast speed, saving labor cost and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

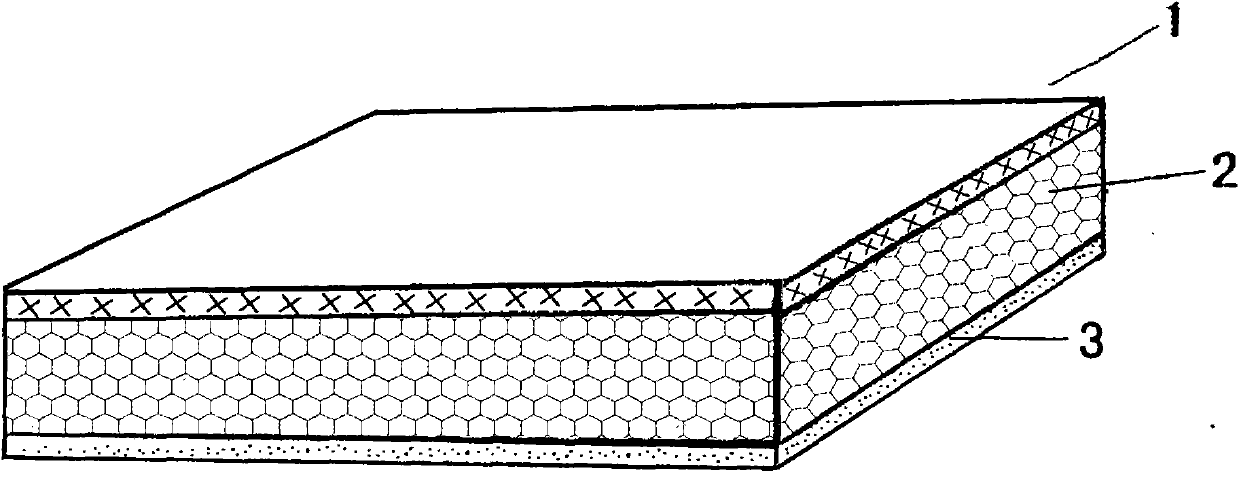

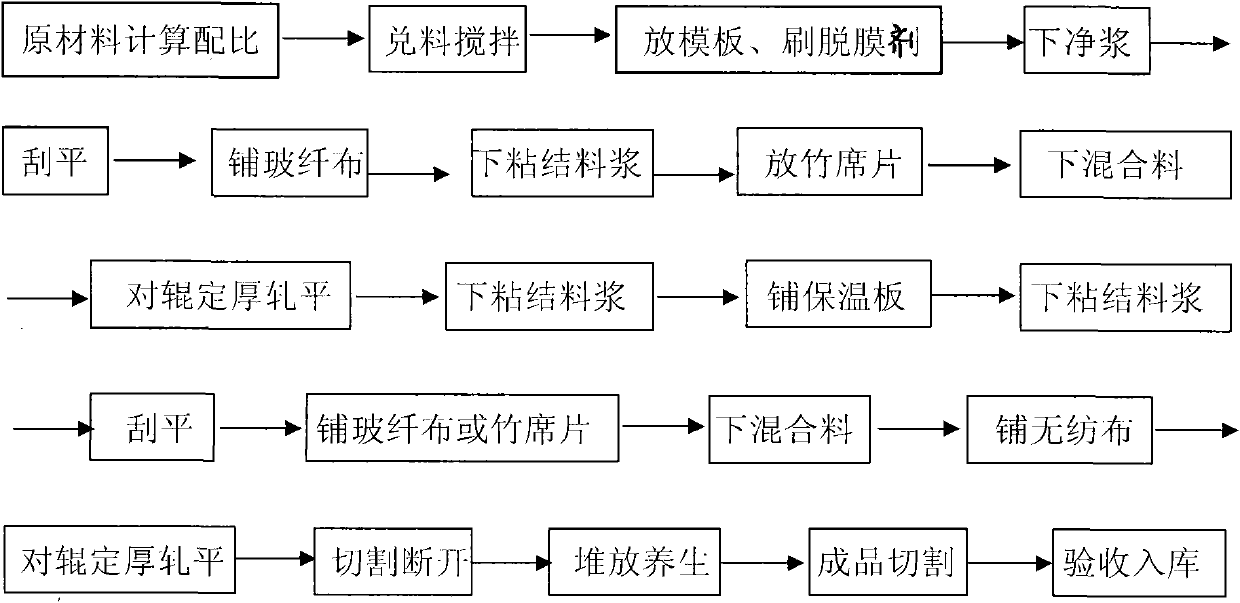

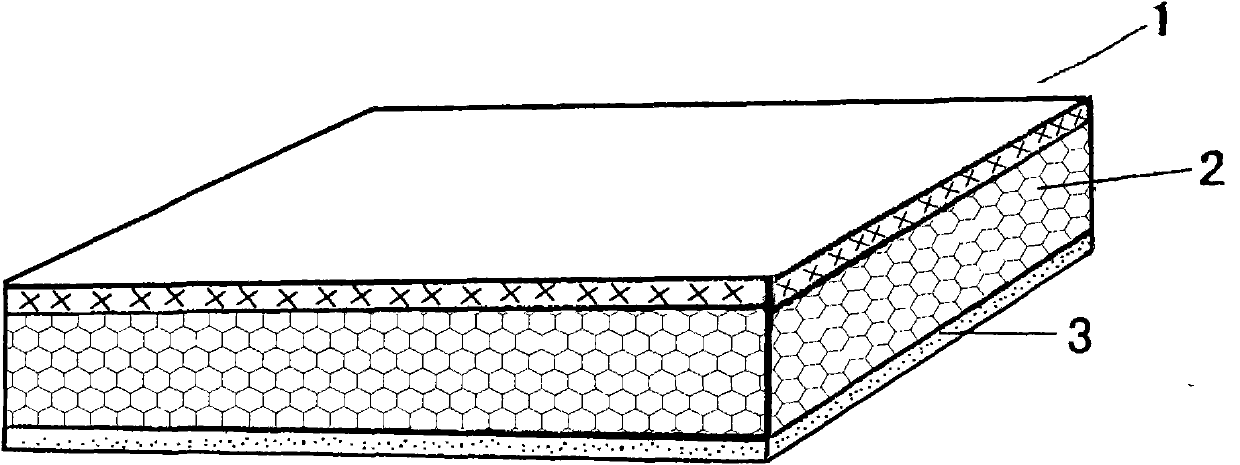

[0015] figure 1 Shown is a structural schematic diagram of the inorganic silicon-magnesium exterior wall thermal insulation composite board of the present invention. One-time molding mechanism inorganic silicon-magnesium exterior wall thermal insulation composite board includes magnesium chloride, magnesium oxide, silicon dioxide, glass fiber cloth, bamboo mat sheet, magnesite filler, modifier made of thermal insulation composite board panel layer 1, middle insulation Layer 2 and thermal insulation composite board bottom layer 3 made of magnesium chloride, magnesium oxide, silicon dioxide, glass fiber cloth, mixed slurry, modifier, thermal insulation composite board panel layer 1, middle insulation layer 2 and thermal insulation composite board bottom board Layer 3 was roll formed in one pass.

[0016] The middle insulation layer 2 is polystyrene foam board or extruded plastic board or polyurethane foam board or other inorganic organic insulation boards, and the thickness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com