Method for producing polypropylene concrete reinforced fiber

A technology of reinforcing fibers and production methods, applied in the field of polypropylene concrete/mortar reinforcing fibers, can solve problems such as preventing the application of polypropylene fibers, and achieve the effects of improved uniformity of fineness, high tensile strength and light specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

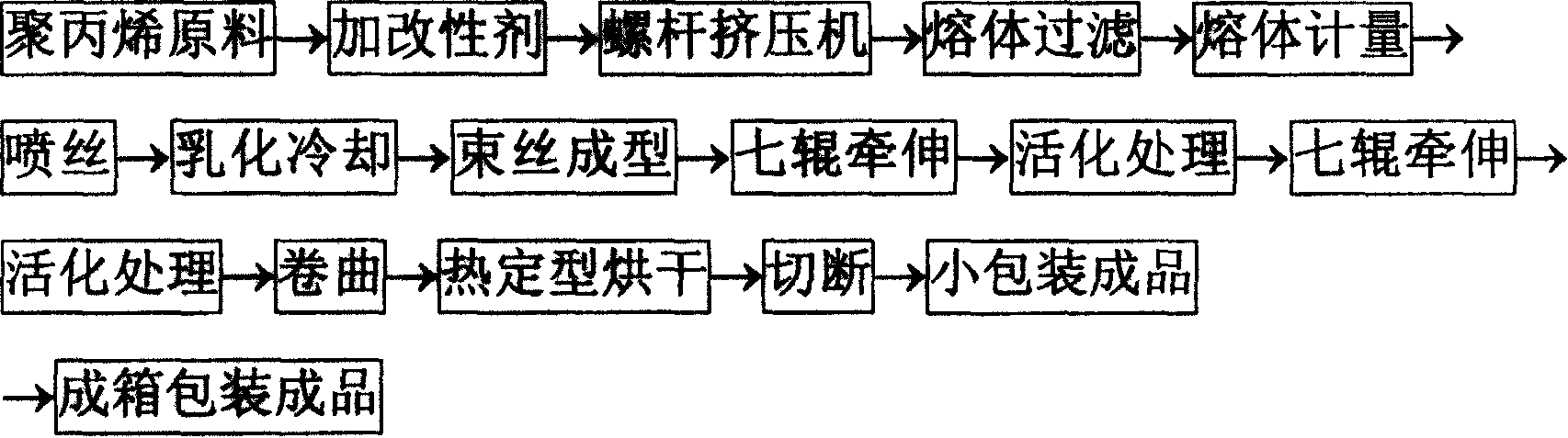

Method used

Image

Examples

Embodiment Construction

[0016] The concrete process parameter of the present invention in production is as follows:

[0017] 1. Screw extruder: 50-70 rpm, pressure 50-90 kg, screw heating area, zone 1 230°C-260°C, zone 2 250°C-290°C, zone 3 270°C-300°C, zone 4 Zone 285°C-320°C, zone five 290°C-320°C, zone six 295°C-340°C, zone seven 290°C-315°C, zone eight 280°C-300°C.

[0018] 2. Melt filter: filter mesh density 250-300 mesh, heating temperature 270°C-290°C.

[0019] 3. Melt metering pump: 50CC-70CC, supply pump turns 18-26 rpm.

[0020] 4. Spinneret φ500mm×5000 holes, hole diameter 0.6-0.8mm, aspect ratio 1:8-12.

[0021] 5. The temperature of the frozen emulsion water is controlled at 5°C-10°C, and the elapsed time is 5-30 meters per minute.

[0022] 6. Hot roll drafting: hot roll temperature 80°C-100°C, activator oil bath temperature 90°C-100°C, activator oil bath concentration 6%-10%, drafting multiple 5-8 times.

[0023] 7. Crimp: The basic requirement is no crimp, and the back pressure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com