Novel method for effectively eliminating static electricity in film coating industry

A technology for removing static electricity and coating film, applied in the direction of static electricity, chemical instruments and methods, coatings, etc., can solve the problems of reduced peel strength, lack of effect, and cure of symptoms rather than root causes, to improve physical and mechanical properties, low electrostatic induction intensity , good effect of removing static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The steps of the efficient method of static electricity removal in the new coating industry:

[0018] An electrostatic liquid is prepared, and the electrostatic liquid is prepared by mixing 5-10 parts of an antistatic solution and 90-95 parts of an organic dilution solvent (ethanol).

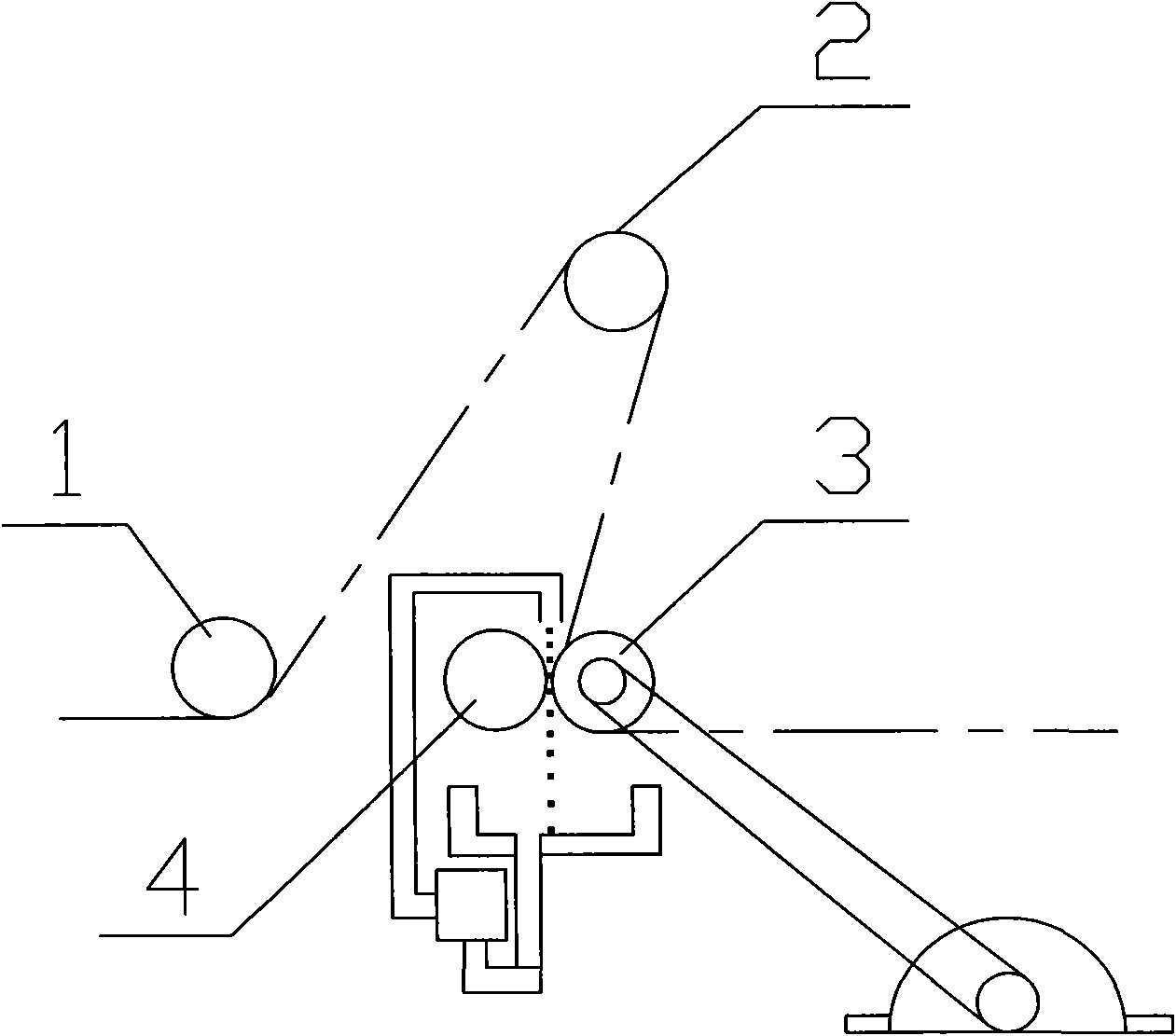

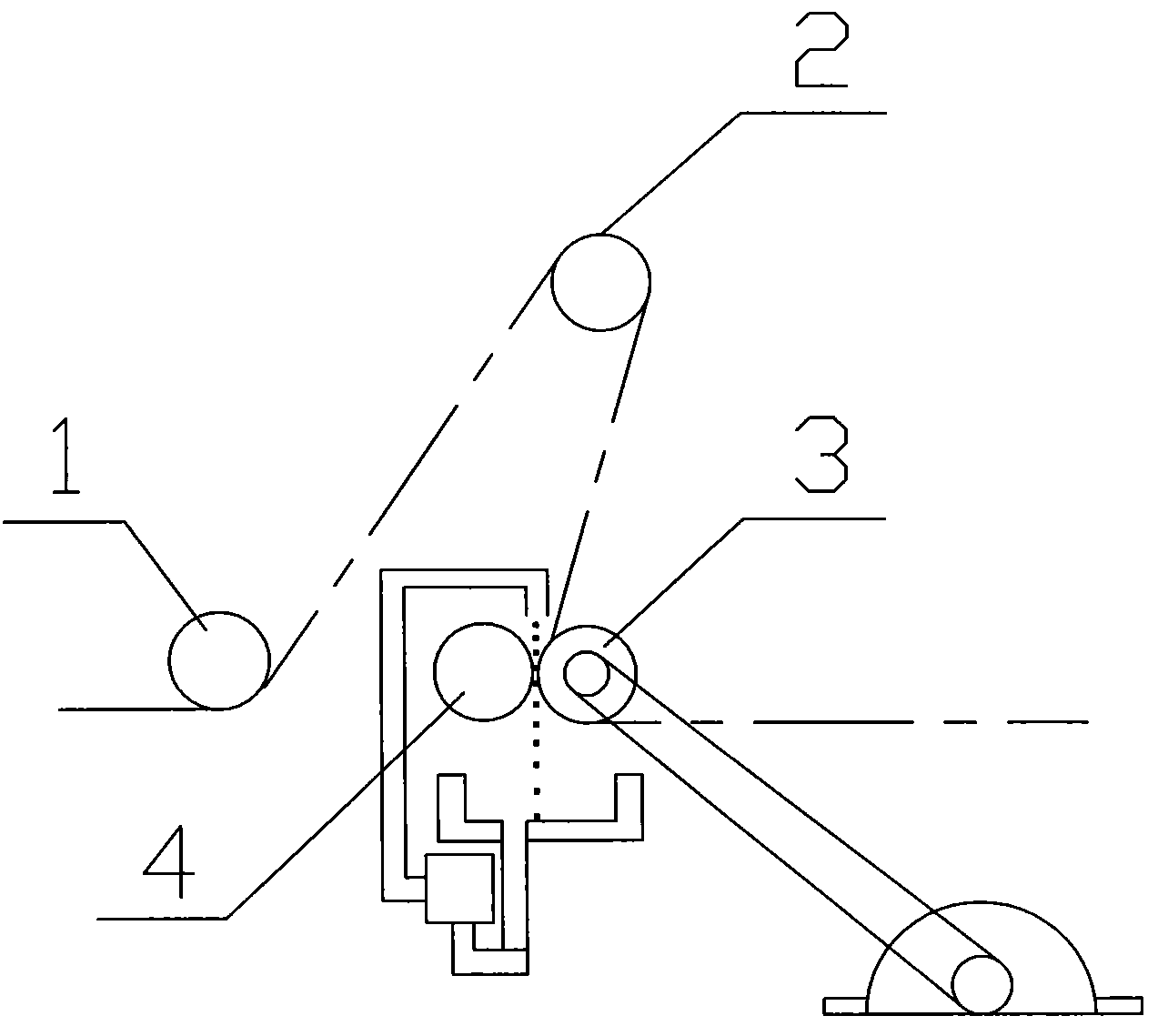

[0019] The dipping coating device is composed of guide roller, coating rubber roller, circulating liquid feeding device, motor, and control electric box, and the dipping coating device is added between the composite device of the coating film equipment and the ultraviolet curing box in the coating film production line.

[0020] Add the electrostatic liquid prepared above into the liquid storage tank of the circulating liquid feeding device, and the protective card film to be coated with the electrostatic liquid is guided by the guide rollers 1 and 2 and enters between the coated rubber rollers 3 and 4, and the coated rubber rollers 3 Driven by the motor, the protective card film is transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com