Organic fiber reinforced inorganic geopolymer composite cementitious material and preparation method thereof

A technology of composite cementitious materials and geopolymers, which is applied in the field of preparation of fiber-reinforced inorganic composite materials, can solve the problem of not finding the patent of polypropylene bundled monofilament fiber-reinforced geopolymers, etc. Development, prevention and formation and development of cracks, the effect of improving flexural strength and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

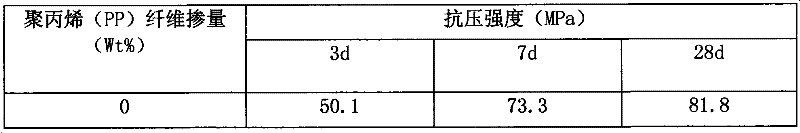

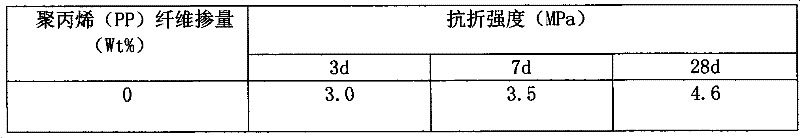

Embodiment 1

[0108]Accurately weigh 1500g of phosphorus slag, and use this as the basis of measurement (100%); adopt the external mixing method, the dosage of the activator sodium silicate is 13%, dissolve the sodium silicate in quantitative water, and the water-slag ratio (w / c) =0.29. Zero content polypropylene bundled monofilament fibers (for reference). Pour phosphorus slag into a double-rotation double-speed slurry mixer for stirring and dispersing; add sodium silicate aqueous solution and stir; stir at a high speed to form a uniform slurry, and put the slurry into a 40mm×40mm×160mm iron triple mold . Vibrate on the glue sand vibrating table, and scrape it with a scraper to obtain a formed phosphorus slag-based geopolymer gelling material. The initial setting time of the sample is 33 minutes, and the final setting time is 124 minutes.

[0109] The molded specimens were cured in the standard curing box for 24 hours, and after demoulding, they were cured in the standard curing box for...

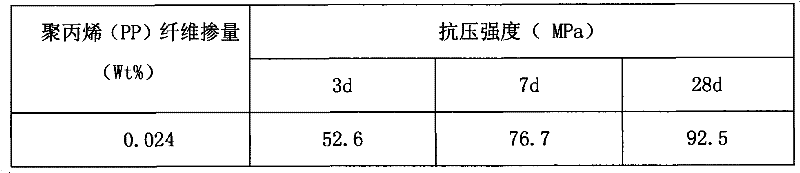

Embodiment 2

[0115] Accurately weigh 1500g of phosphorus slag, and use this as the basis of measurement (100%); adopt the external mixing method, and the dosage of the activator sodium silicate is 13%; dissolve the sodium silicate into the quantitative water; dissolve the sodium silicate into the quantitative water , w / c=0.29. The dosage of polypropylene fiber is 0.024%. The polypropylene fiber is pre-dispersed in the phosphorus slag, and then poured into a double-rotation and double-speed pulp mixer for stirring and dispersing; the sodium silicate aqueous solution is added for stirring; high-speed stirring forms a uniformly mixed slurry Body, the slurry is packed into 40mm * 40mm * 160mm iron triple mold. Vibrate on a glue sand vibrating table, and scrape it flat with a scraper to obtain a formed organic fiber-reinforced phosphorus slag-based geopolymer composite gelling material.

[0116] The molded specimens were cured in the standard curing box for 24 hours, and after demoulding, they...

Embodiment 3

[0122] All preparation processes are the same as in Example 2. Only changing the PP fiber content to 0.036%, the experimental results are shown in Table 5 and Table 6.

[0123] Table 5: Compressive strength of PP fiber reinforced phosphorus slag-based geopolymer composite cementitious materials

[0124]

[0125] Table 6: Flexural strength of PP fiber reinforced phosphorus slag-based geopolymer composite cementitious materials

[0126]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com