Alkali-activated lignin-based active carbon fibers and preparation method thereof

An activated carbon fiber and lignin-based technology, which is applied in fiber treatment, fiber chemical characteristics, rayon chemical post-treatment, etc., can solve the problems of high production cost and sustainability of activated carbon fiber, and achieve waste utilization, use reduction, and cost reduction. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

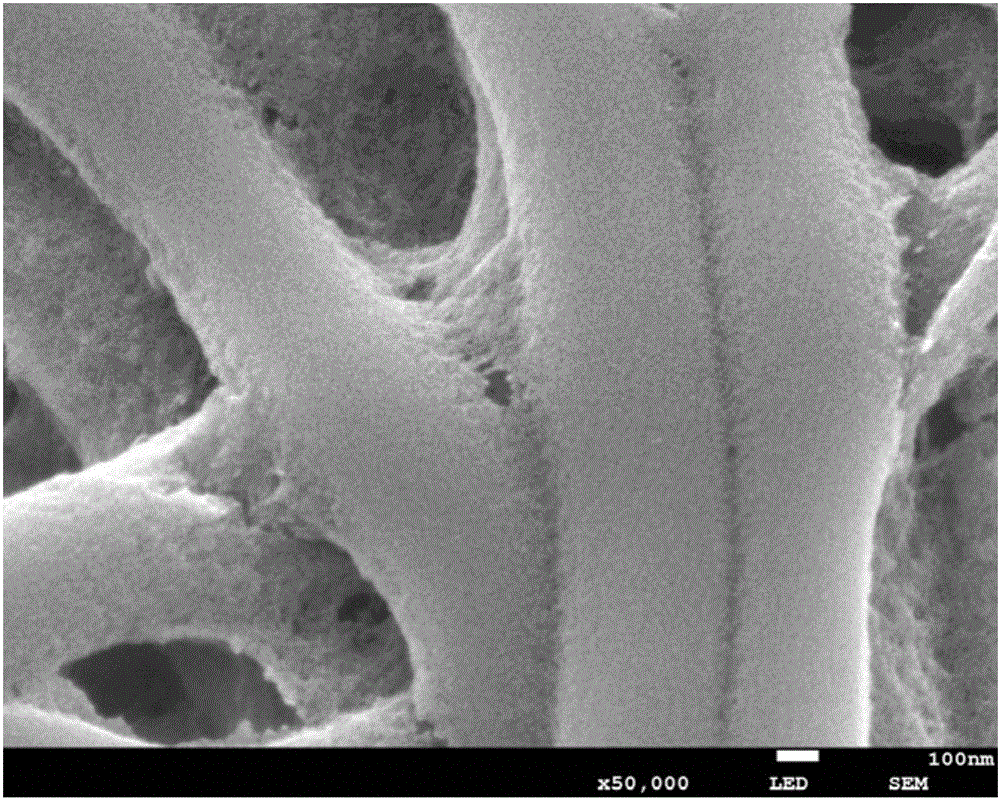

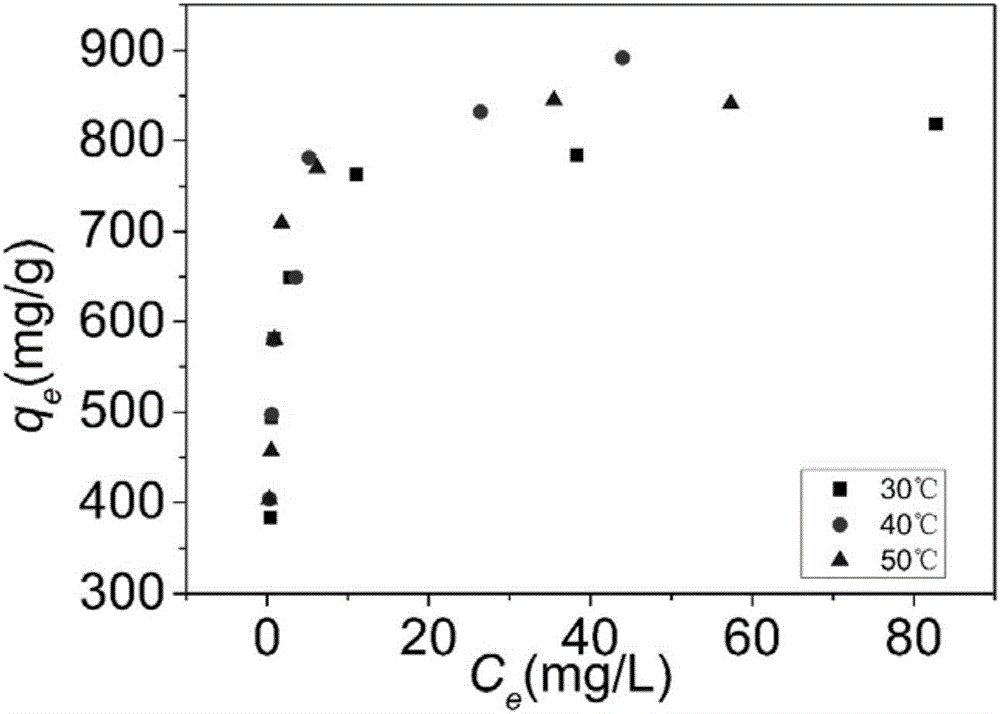

Image

Examples

Embodiment 1

[0029] A kind of preparation method of the lignin-based activated carbon fiber of alkali activation, described preparation method comprises the steps:

[0030] Preparation of lignin: Grind corn stalks from enzymatic hydrolysis, cook with sodium hydroxide, filter, add the filtrate to 10 times its volume of deionized water, adjust the pH value to 1 with hydrochloric acid, let stand overnight, lignin is precipitated Finally, centrifuge at 2000r / min for 30min, and dry at 60°C for 24h to obtain lignin;

[0031] Preparation of spinning solution: Add polyethylene oxide to N,N-dimethylformamide, stir and dissolve at 60°C, then add lignin, stir and dissolve at 30°C to obtain spinning solution, the polyethylene oxide, N , the weight ratio of N-dimethylformamide to lignin is 1:19:80;

[0032] High-voltage electrospinning: Add the spinning liquid into the syringe, the distance between the needle of the syringe and the drum is 20cm, the needle of the syringe is connected to a positive hig...

Embodiment 2

[0036] A kind of preparation method of the lignin-based activated carbon fiber of alkali activation, described preparation method comprises the steps:

[0037] Preparation of lignin: Grind corn stalks, cook with sulfate method, filter, add the filtrate to 10 times its volume of deionized water, adjust the pH value to 2 with hydrochloric acid, let it stand overnight, after the lignin is precipitated, 3000r / Centrifuge for 40 minutes, dry at 80°C for 20 hours to obtain lignin;

[0038] Preparation of spinning solution: Add polyvinyl nitrile to N,N-dimethylformamide, stir and dissolve at 60°C, then add lignin, stir and dissolve at 30°C to obtain spinning solution, the polyvinyl nitrile, N , the weight ratio of N-dimethylformamide to lignin is 0.6:19.4:60;

[0039] High-voltage electrospinning: Add the spinning liquid into the syringe, the distance between the needle of the syringe and the drum is 10cm, the needle of the syringe is connected to a positive high-voltage power suppl...

Embodiment 3

[0043] A kind of preparation method of the lignin-based activated carbon fiber of alkali activation, described preparation method comprises the steps:

[0044] Preparation of lignin: Grind wheat straw, cook with alkali ethanol method, filter, add the filtrate to 10 times its volume of deionized water, adjust the pH value to 3 with hydrochloric acid, let stand overnight, after lignin is precipitated, 4500r / min Centrifuge for 10 minutes and dry at 40°C for 36 hours to obtain lignin;

[0045] Preparation of spinning solution: Add polyethylene oxide to N,N-dimethylformamide, stir and dissolve at 60°C, then add lignin, stir and dissolve at 30°C to obtain spinning solution, the polyethylene oxide, N , the weight ratio of N-dimethylformamide to lignin is 0.2:19.8:46.7;

[0046] High-voltage electrospinning: Add the spinning liquid into the syringe, the distance between the needle of the syringe and the drum is 25cm, the needle of the syringe is connected to a positive high-voltage p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com