Method for preparing room-temperature curing one-component alkali-activated cement with calcination at low temperature

A technology for alkali-activated cement and normal temperature curing, applied in the field of new cement materials, can solve problems such as inconvenience in use, and achieve the effects of improving the convenience of use, easy availability of raw materials, and reducing preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with specific experimental examples. The equipment used in the embodiments of the present invention is conventional equipment, and the raw materials used are conventional raw materials.

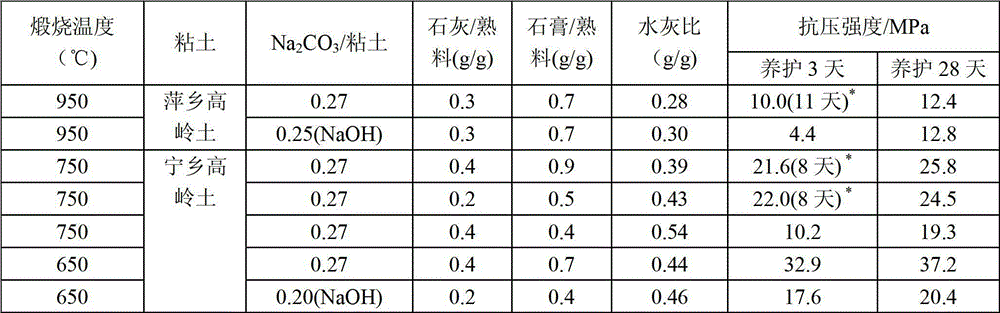

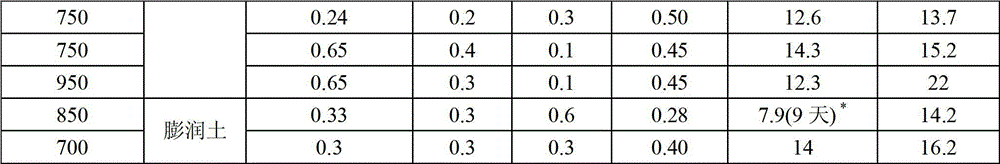

[0012] The raw materials of the three silicon-containing aluminum oxides used in the examples of the present invention are clays of Ningxiang kaolin, Pingxiang kaolin and Linli bentonite respectively, and their chemical compositions are shown in Table 1. The basic activators used are analytically pure NaOH and anhydrous Na 2 CO 3 . NaOH or anhydrous Na 2 CO 3 Ball mill with the above clay until the particle size is 200 mesh sieve and less than 10% of the total mass, then calcined at 650~950°C for 2~4 hours to obtain clinker, and then ball mill the cooled clinker powder to a fineness of The remaining 200 mesh sieves account for 10% clinker powder in the total mass. Clinker powder is mixed with lime and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com