Alkali activated fly ash/slag foam concrete and preparation method thereof

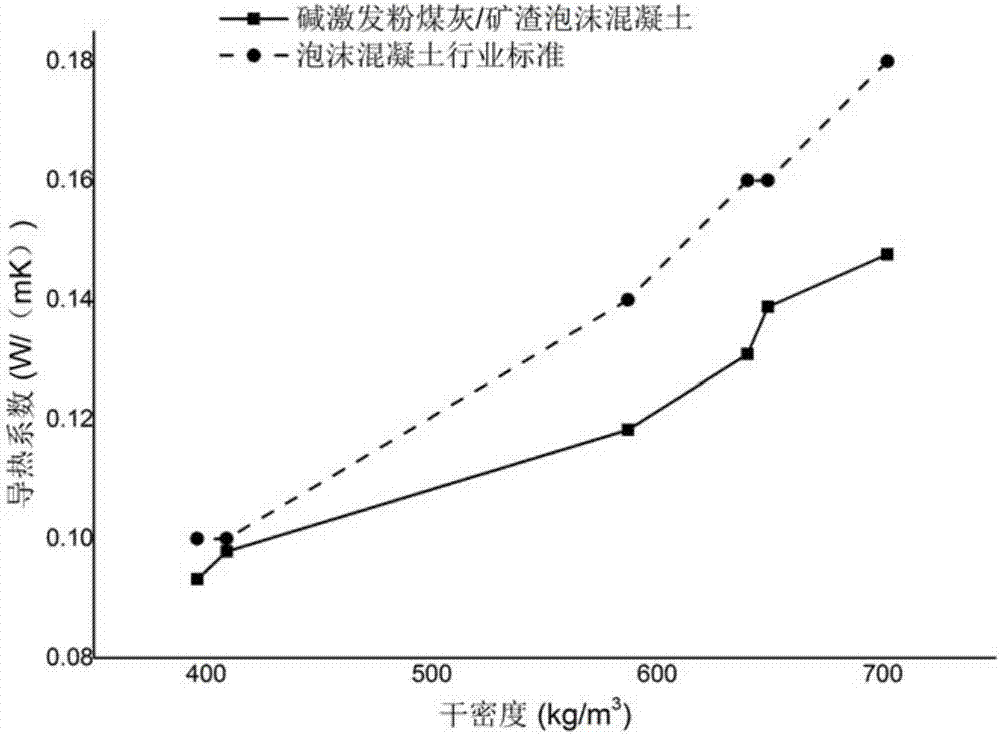

A technology of foam concrete and fly ash, which is applied to ceramic products, other household appliances, household appliances, etc., can solve the problems of high energy consumption, large capacity, and high thermal conductivity of foam concrete, and achieve high mechanical properties and acid and alkali corrosion resistance Good thermal conductivity, small thermal conductivity, and good heat insulation/heat preservation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

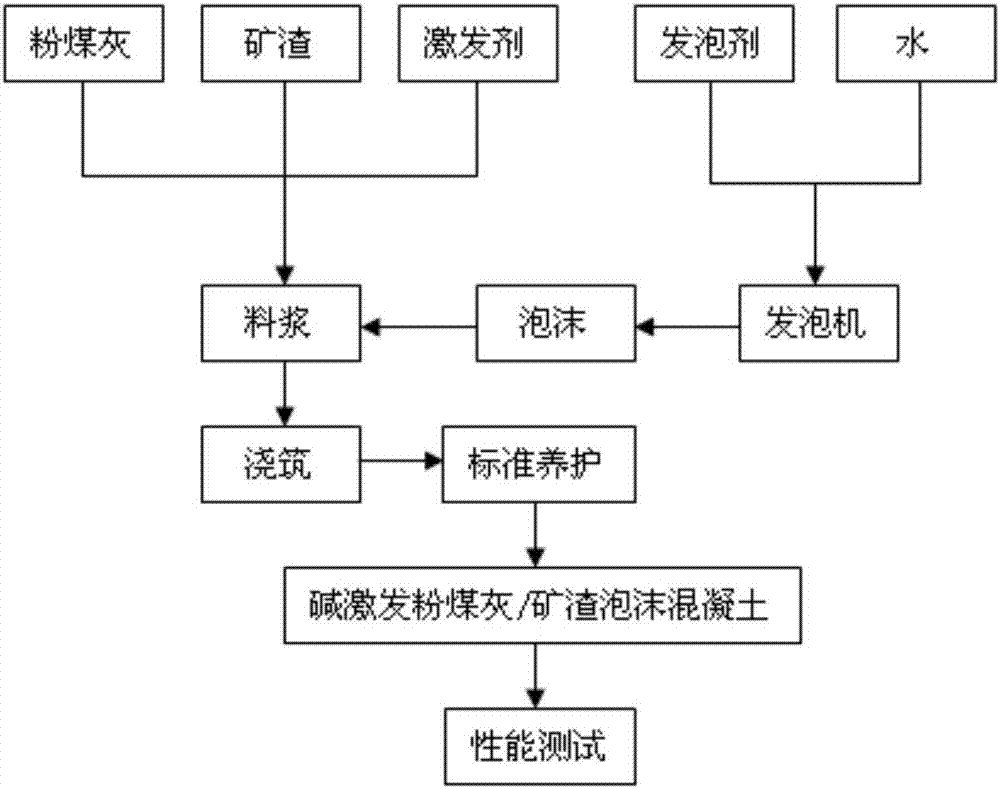

[0047] A kind of alkali-activated fly ash / slag foam concrete, its composition and volume percentage are as follows:

[0048] Fly ash: 10.77%, slag: 4.62%, alkali activator: 18.11%, foam: 66.50%.

[0049] Wherein, the alkali activator is a mixture of sodium hydroxide and water glass. The dosage of sodium hydroxide is 7.68g; the dosage of water glass is 82.36g; the modulus of the alkali activator is 1.5; the mass ratio of water / ash body is 0.4.

[0050] Preparation method: first, pour fly ash and slag into a mixer and stir evenly; second, add alkali activator in proportion and stir to prepare slurry; at the same time, dilute foaming agent and water at a ratio of 1:30, and adjust Vacuum foaming machine, foaming by physical method to prepare dense and stable foam; weigh the required volume of foam and add it, first stir slowly for 3', then stir quickly for 30" until the foam is evenly dispersed in the slurry, and made Freshly mixed slurry; finally, inject the slurry into a mold,...

Embodiment 2

[0054] A kind of alkali-activated fly ash / slag foam concrete, its composition and volume percentage are as follows:

[0055] Fly ash: 10.77%, slag: 4.62%, alkali activator: 19.93%, foam: 64.68%.

[0056] Wherein, the alkali activator is a mixture of sodium hydroxide and water glass. The dosage of sodium hydroxide is 7.68g; the dosage of water glass is 82.36g; the modulus of the alkali activator is 1.5; the mass ratio of water / ash body is 0.45.

[0057] Preparation method: first, pour fly ash and slag into a mixer and stir evenly; second, add alkali activator in proportion and stir to prepare slurry; at the same time, dilute foaming agent and water at a ratio of 1:30, and adjust Vacuum foaming machine, foaming by physical method to prepare dense and stable foam; weigh the required volume of foam and add it, first stir slowly for 3', then stir quickly for 30" until the foam is evenly dispersed in the slurry, and made Freshly mixed slurry; finally, inject the slurry into a mold...

Embodiment 3

[0060] A kind of alkali-activated fly ash / slag foam concrete, its composition and volume percentage are as follows:

[0061] Fly ash: 4.62%, slag: 10.77%, alkali activator: 18.11%, foam: 66.50%.

[0062] Wherein, the alkali activator is a mixture of sodium hydroxide and water glass. The dosage of sodium hydroxide is 7.68g; the dosage of water glass is 82.36g; the modulus of the alkali activator is 1.5; the mass ratio of water / ash body is 0.4.

[0063] Preparation method: first, pour fly ash and slag into a mixer and stir evenly; second, add alkali activator in proportion and stir to prepare slurry; at the same time, dilute foaming agent and water at a ratio of 1:30, and adjust Vacuum foaming machine, foaming by physical method to prepare dense and stable foam; weigh the required volume of foam and add it, first stir slowly for 3', then stir quickly for 30" until the foam is evenly dispersed in the slurry, and made Freshly mixed slurry; finally, inject the slurry into a mold,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com