Flyash-based polymer concrete material and preparation method thereof

A fly ash and polymer technology, applied in the field of concrete materials, can solve the problems of easy cracking, high strength variability and low strength of the cement-stabilized crushed stone layer, and achieves favorable mechanical properties for pavement roadbed and base construction and planning, and good mechanical properties. , the effect of high early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The geopolymer concrete material of the present invention has a production and construction method similar to ordinary cement-stabilized crushed stone materials, and it is mixed and constructed at normal temperature on site during use. The specific preparation method is as follows:

[0025] (1) Geopolymer slurry composition: fly ash 35%, metakaolin 10%, cement 10.5%, coal gangue and slag 3.5%, water glass 25%, potassium silicate solution 12.5%, retarder 0.5%, Deionized water 3%. Add the raw materials of the above components into the mixer and mix them evenly on site;

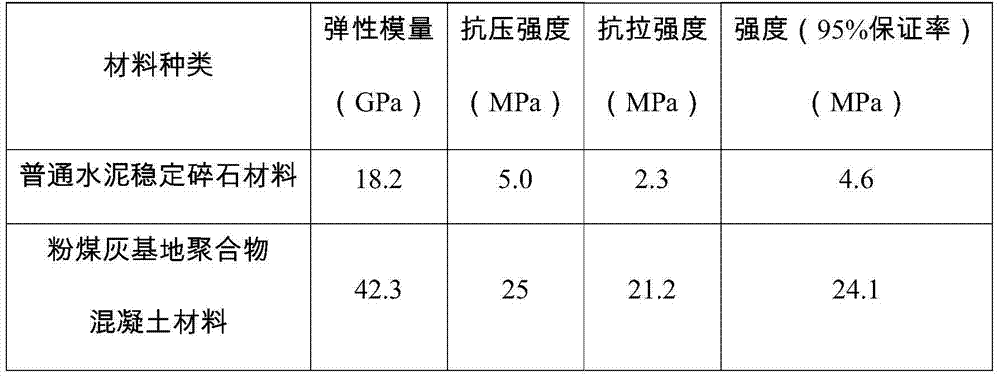

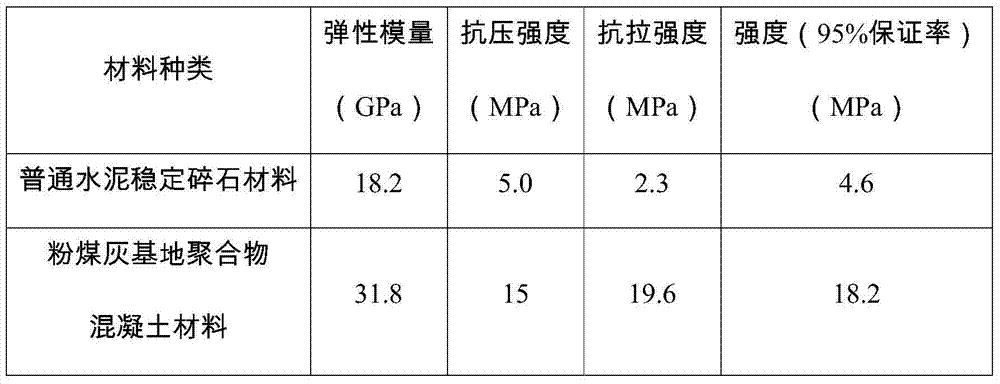

[0026] (2) Preparation of geopolymer concrete material: mix and stir the prepared geopolymer slurry and certain graded aggregates in proportion on site for 2 to 4 minutes until the aggregates are evenly dispersed to make fly ash-based polymer concrete Material. The ratio of the aggregate to the geopolymer slurry is: 89 parts of the aggregate and 11 parts of the geopolymer slurry. See Table 1 for aggre...

Embodiment 2

[0033] The geopolymer concrete material of the present invention has a production and construction method similar to ordinary cement-stabilized crushed stone materials, and it is mixed and constructed at normal temperature on site during use. The specific preparation method is as follows:

[0034] (1) Geopolymer slurry composition: fly ash 45%, metakaolin 5%, cement 6.5%, coal gangue and slag 3.5%, water glass 29%, potassium silicate solution 8%, retarder 1%, Deionized water 2%. Add the raw materials of the above-mentioned components into the mixer on site and mix them evenly.

[0035] (2) Preparation of geopolymer concrete material: mix and stir the prepared geopolymer slurry and certain graded aggregates in proportion on site for 2 to 4 minutes until the aggregates are evenly dispersed to make fly ash-based polymer concrete Material. The ratio of the aggregate to the geopolymer slurry is: 89 parts of the aggregate and 11 parts of the geopolymer slurry. The aggregate grad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com