Conductive geopolymer preparation method

A geopolymer and polymer technology, applied in the field of preparation of conductive geopolymers, can solve the problems of poor graphene dispersion effect and the like, and achieve the effect of good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1: Take 20g of graphene with a thickness of 0.8nm, an extended size of 2μm, and an oxygen content of 10%, and another 10g of sodium dodecylbenzenesulfonate and 120g of water, according to the weight of 1:0.5:6 Specific mixing, placed in a nano-sand mill with a grinding aid medium of high-strength glass beads and a grinding speed of 1000 rpm for grinding and dispersing for 2 hours, and then placed in a high-frequency ultrasonic dispersing machine with a vibration frequency of 40kHZ for 50 minutes. Minutes, obtain the graphene dispersion liquid of preliminary dispersion.

[0029] Step 2: Take 1.5 silicon modulus, 1800g of liquid sodium silicate solution with a solid content of 40%, 100g of the initially dispersed graphene dispersion, mix and stir at a weight ratio of 1:0.056, and then add the sodium silicate solution to the mixed solution. Mix 19 g of 1% sodium alginate by weight of the solution. Place it again in a nano-sand mill for grinding and dispersing for 2 h...

Embodiment 2

[0034] Step 1: Take 60g of graphene with a thickness of 1nm, an extended size of 3μm, and an oxygen content of 15%, and another 18g of sodium citrate and 300g of water, mix them in a weight ratio of 1:0.3:5, and place them in an auxiliary Grinding and dispersing for 1.5 hours in a nano-sand mill with high-strength ceramic beads and a grinding speed of 1500 rpm, and then placing it in a high-frequency ultrasonic dispersing machine with a vibration frequency of 45kHZ for 40 minutes to obtain preliminary dispersed graphite olefin dispersion.

[0035] Step 2: Take 2000g of liquid sodium silicate solution with a silicon modulus of 1.8 and a solid content of 45%, and 340g of the initially dispersed graphene dispersion, mix and stir at a weight ratio of 1:0.17, and then add the Mix solution weight 0.5% sodium carboxymethylcellulose 11.7g. Place it again in a nano-sand mill for grinding and dispersing for 1.5 hours, and further disperse in a high-frequency ultrasonic disperser for 40...

Embodiment 3

[0040] Step 1: Take 110g of graphene with a thickness of 1.2nm, an extended size of 4μm, and an oxygen content of 20%, and another 22g of polyvinylpyrrolidone and 440g of water, mix them in a weight ratio of 1:0.2:4, and place in The grinding aid medium is high-strength glass beads, and the grinding speed is 2000 rpm in a nano-sand mill for grinding and dispersing for 1 hour, and then placed in a high-frequency ultrasonic dispersing machine with a vibration frequency of 50kHZ for 30 minutes to obtain a preliminary dispersion. Graphene dispersion.

[0041] Step 2: Take 2200g of liquid sodium silicate solution with a silicon modulus of 2.2 and a solid content of 50%, 550g of the initially dispersed graphene dispersion, mix and stir at a weight ratio of 1:0.25, and then add the Mix 2.2 g of 0.08% sodium polyacrylate by weight of the solution. Put it again in the aforementioned nano-sand mill for grinding and dispersing for 1 hour, and further ultrasonically oscillate and dispers...

PUM

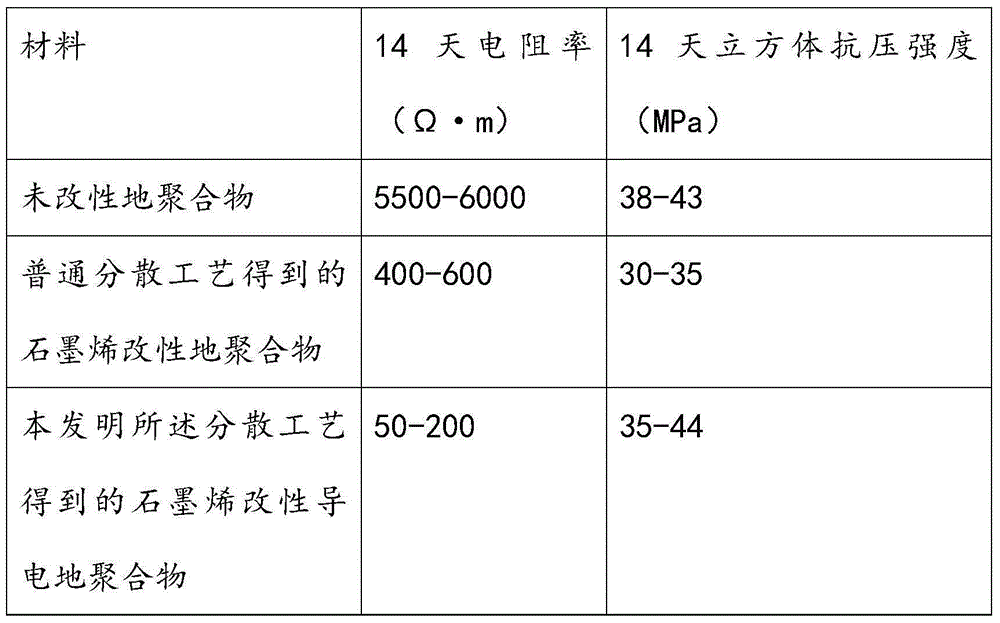

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com