Composite alkali-activating low-carbon cement and preparation method of low-carbon cement

A technology of alkali excitation and carbon cement, which is applied in the field of building materials, can solve the problems of environmental pollution, consumption of large limestone and clay, and large consumption of energy and resources, and achieve the effect of changing dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

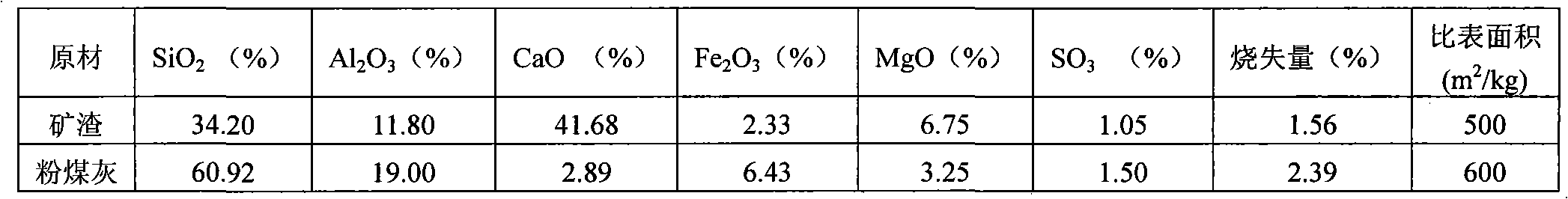

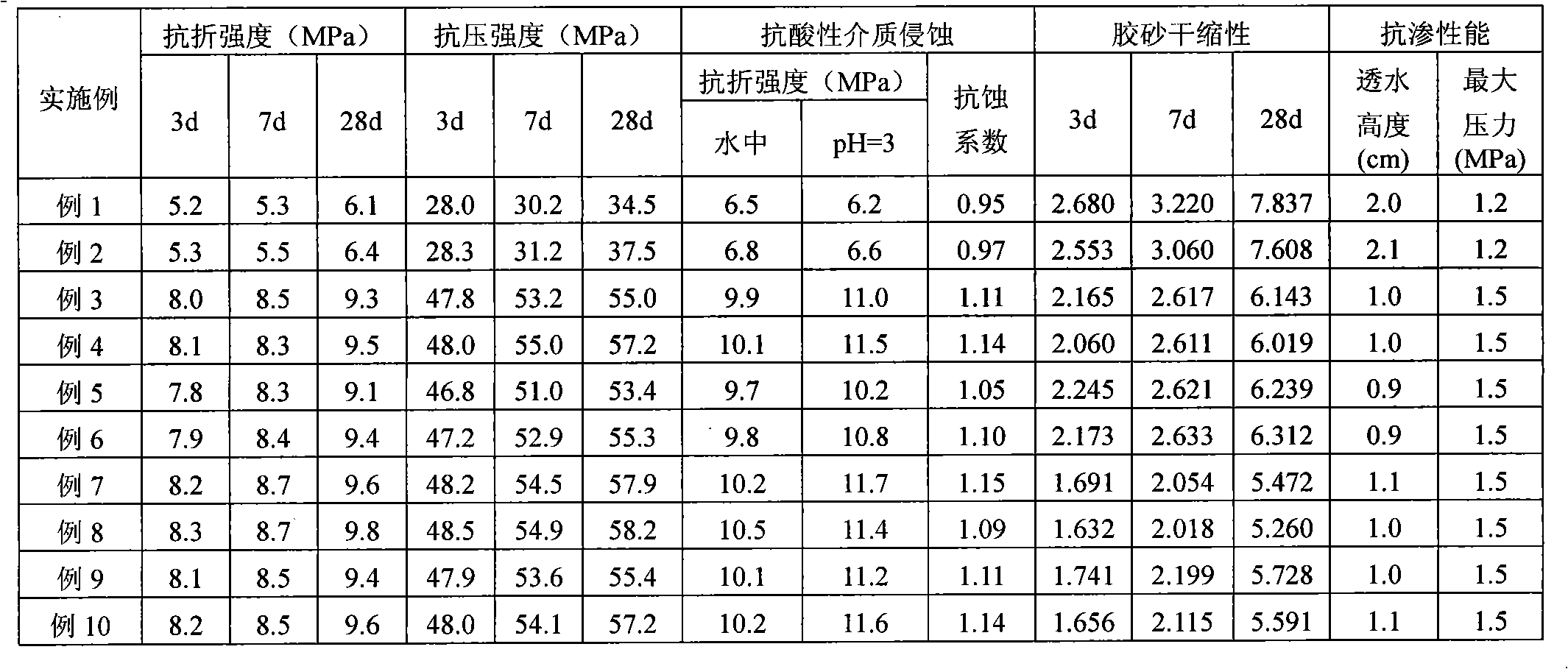

Embodiment 1

[0016] a. The slag and fly ash are mixed with a mass ratio of 4:6, wherein 10% of alkali activator is mixed, 5% of lime coagulation agent is mixed, and 3% of natural zeolite is mixed as nucleating agent to control the whole The water-binder ratio of the system is 0.38, that is, the sample is prepared. Wherein the preparation of the alkali activator is: the ratio of water glass and sodium hydroxide having a modulus of 1.2 is 3:7.

[0017] b. Referring to the rapid determination method of cement sulfate corrosion resistance, the prepared samples were cured under standard conditions for 1 day and removed from the mold, placed in a standard curing room for 6 days, and then divided into two groups, one group was cured in 20°C water, and the other One group was soaked in the acidic medium with pH=3 for 28 days, and the flexural strength was measured and the corrosion resistance coefficient was calculated.

[0018] c. The determination of the drying shrinkage value of the mortar is ...

Embodiment 2

[0021] The slag and fly ash are mixed in a mass ratio of 4:6, 10% of alkali activator, 5% of lime coagulant, and 4% of natural zeolite are mixed in as nucleating agent to control the The water-binder ratio is 0.36, that is, the sample is prepared. Wherein the preparation of alkali activator is: the ratio of water glass and sodium hydroxide with a modulus of 1.2 is 4:6. All the other steps are the same as b, c, d in embodiment 1.

Embodiment 3

[0023]Mix slag and fly ash at a mass ratio of 6:4, add 10% of alkali activator, 5% of lime coagulant, and 3% of natural zeolite as nucleating agent to control the The water-binder ratio is 0.38, that is, the sample is prepared. Wherein the preparation of alkali activator is: the ratio of water glass and sodium hydroxide with a modulus of 1.2 is 4:6. All the other steps are the same as b, c, d in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com