Gas-and-solid-fired environment-friendly industrial boiler

An industrial boiler and environmental protection technology, which is used in steam boilers, combustion of block fuel and gaseous fuel, steam generation, etc., can solve the problems of uneven particle size, low thermal efficiency of boilers, and high operating costs, and achieve serious pollution emissions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

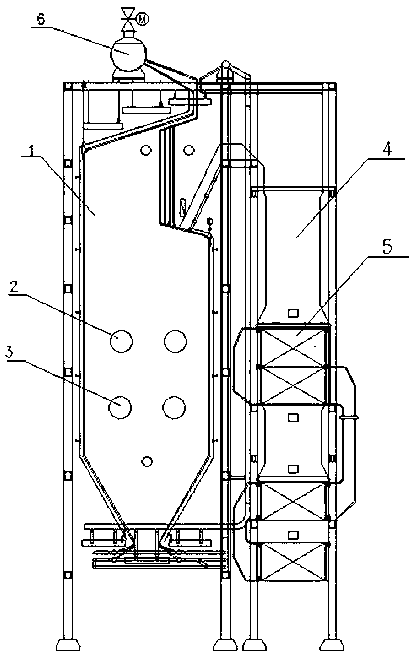

[0012] Such as figure 1 As shown, a gas-solid dual-combustion environmental protection industrial boiler includes a boiler body 1 arranged vertically. The boiler body 1 adopts a membrane wall structure. The interior of the boiler body 1 is arranged in an n-shape as a whole. The gas burner 2 and the solid burner 3 communicated with the furnace, the solid burner 3 adopts a swirl burner, the gas burner 2 is located above the solid burner 3, the boiler body between the solid burner 3 and the gas burner 2 1 is fixed with partitions, and the walls around the furnace are covered with membrane-type water-cooled walls. The furnace forms an ascending flue, which communicates with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com