Composite pile with high permanent stability protection layer and its production and construction method

A construction method and durability technology, applied in sheet pile walls, foundation structure engineering, climate change adaptation, etc., can solve the problems of materials that are difficult to bear loads as concrete piles, and high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] The present invention has a kind of composite pile with high durability protective layer, and its structural composition is as follows:

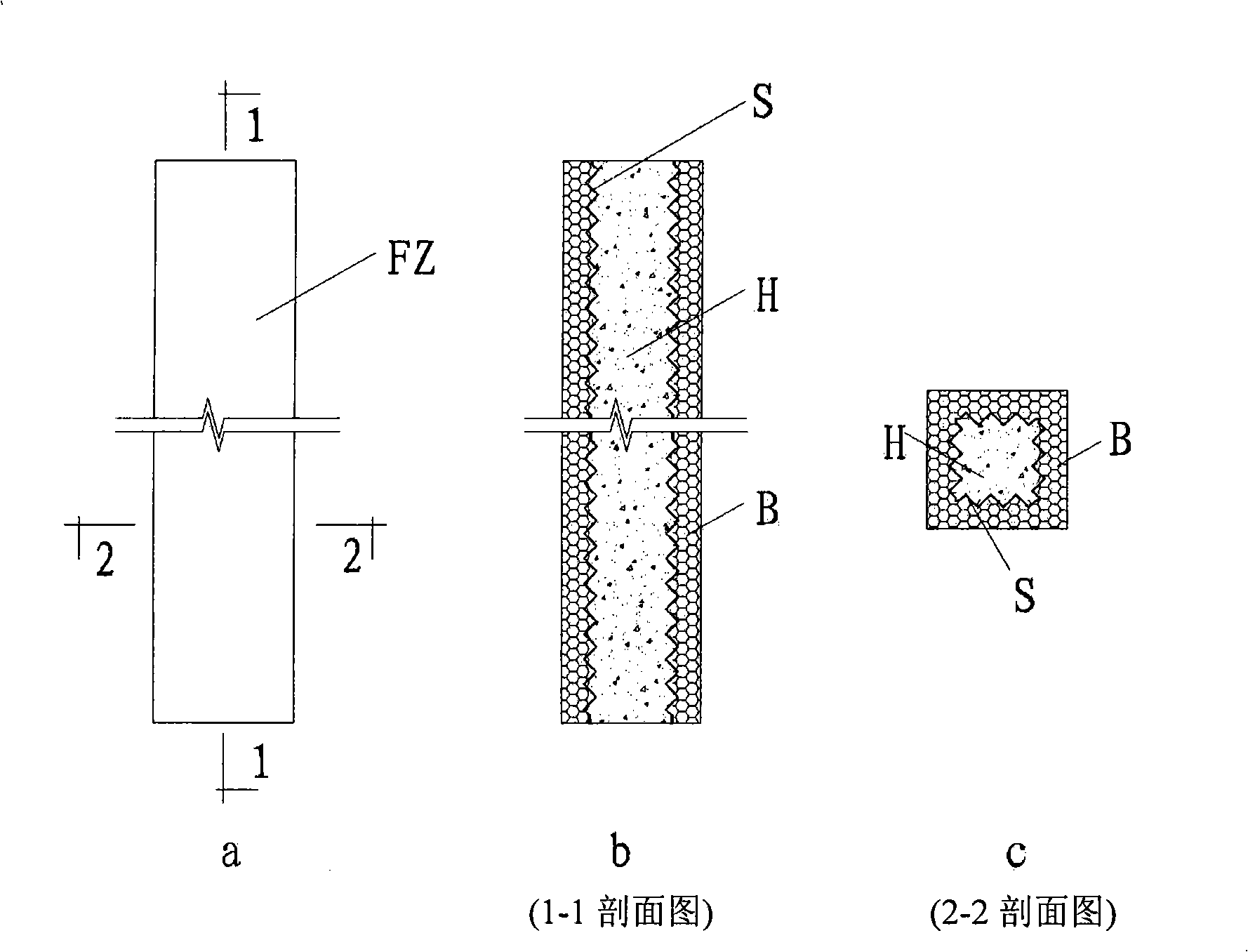

[0104] A composite pile with a high-durability protective layer consists of two parts: a core load-bearing structure and a high-durability protective layer (see figure 1 As shown), the high-durability protective layer wraps the core load-bearing structure to protect the load-bearing structure from environmental corrosion. The connection between the high-durability protective layer and the core load-bearing structure is the bonding, friction, and occlusal connection between the two materials.

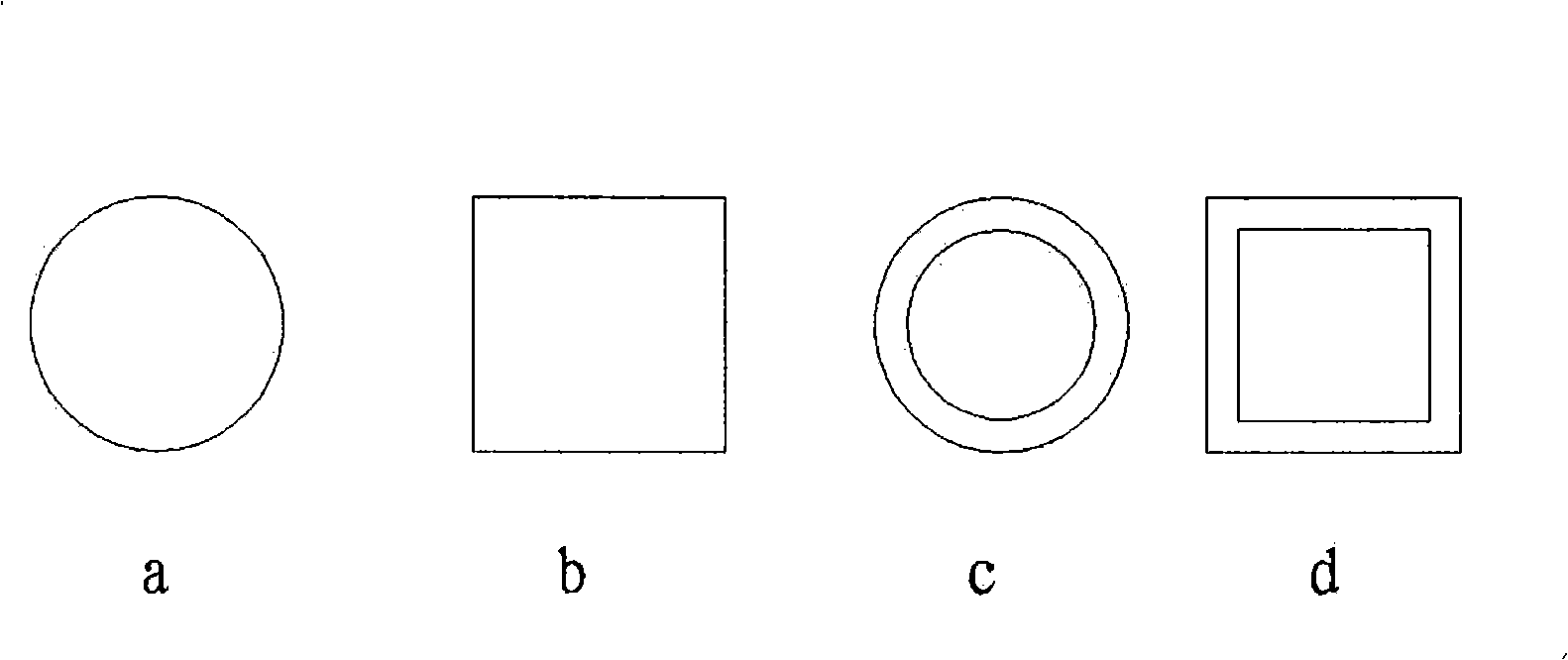

[0105] Composite pile with high durability protective layer, its core load-bearing structure part is plain concrete material; it is designed according to the requirements of bearing capacity according to the current national pile foundation and related specifications, circular cross-section, diameter 800mm, concrete strength grade C20.

[0106]...

Embodiment 2

[0116] A composite pile with a high-durability protective layer consists of two parts: a core load-bearing structure and a high-durability protective layer (see figure 1 As shown), the high-durability protective layer wraps the core load-bearing structure to protect the load-bearing structure from environmental corrosion.

[0117] A composite pile with a high-durability protective layer, the connection between the durable protective layer and the core load-bearing structure is the connection mode of cementation, friction, and occlusal between the two materials.

[0118] The composite pile with a high-durability protective layer, its core load-bearing structure part is ordinary reinforced concrete material; its reinforcement, cross-sectional form and structure are designed according to the requirements of the bearing capacity according to the current national pile foundation and related specifications, circular cross-section, diameter 300mm, plain concrete pile, concrete streng...

Embodiment 3

[0128] The present invention has a kind of composite pile with high durability protective layer, and its structural composition is as follows:

[0129] A composite pile with a high-durability protective layer consists of two parts: a core load-bearing structure and a high-durability protective layer (see figure 1 As shown), the high-durability protective layer wraps the core load-bearing structure to protect the load-bearing structure from environmental corrosion. The connection between the high-durability protective layer and the core load-bearing structure is the bonding, friction, and occlusal connection between the two materials.

[0130] The composite pile with a high-durability protective layer, its core load-bearing structure is made of reinforced concrete; it is designed according to the requirements of the bearing capacity according to the current national pile foundation and related specifications, with a circular cross-section, a diameter of 1300mm, a concrete stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com