Production method of weather-proof multilayer composite wood floor

A multi-layer composite and production method technology, which is applied in the jointing of wooden veneers, humidity control of wood, wood processing equipment, etc., can solve the problems of large drying stress, poor water resistance, warping and deformation of the surface board, and achieve weather resistance Poor performance, stress reduction effect, and small deformation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

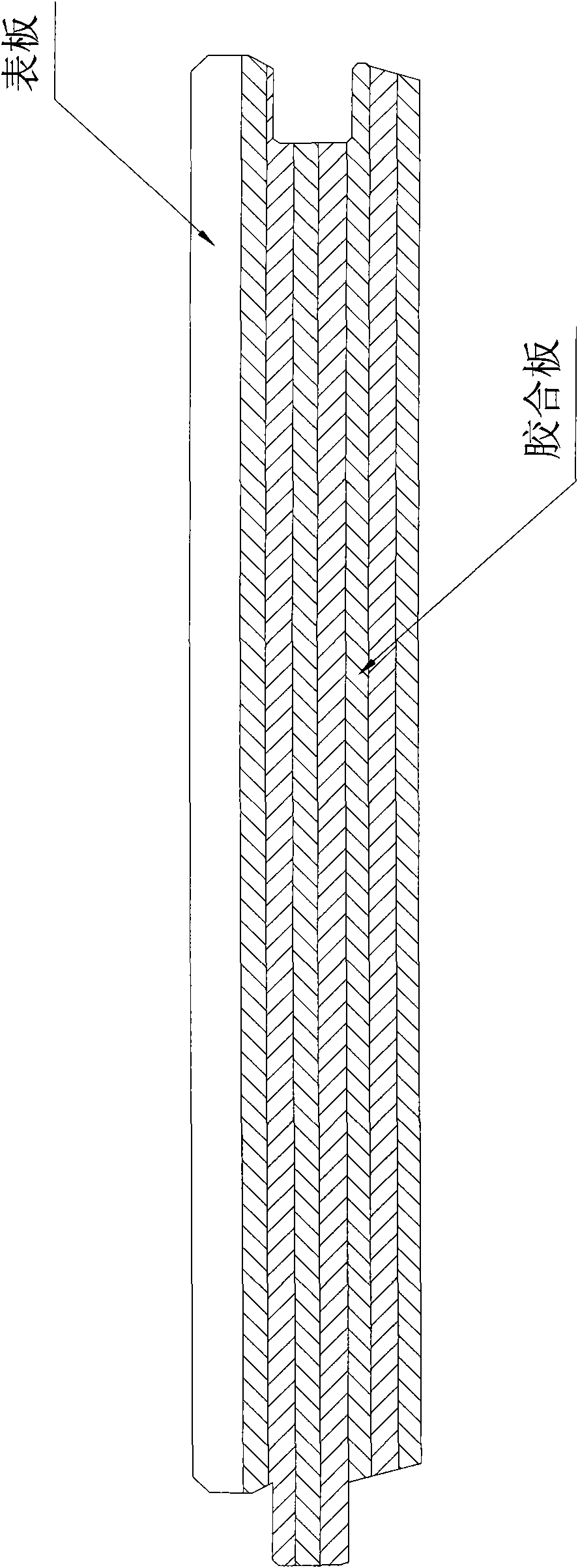

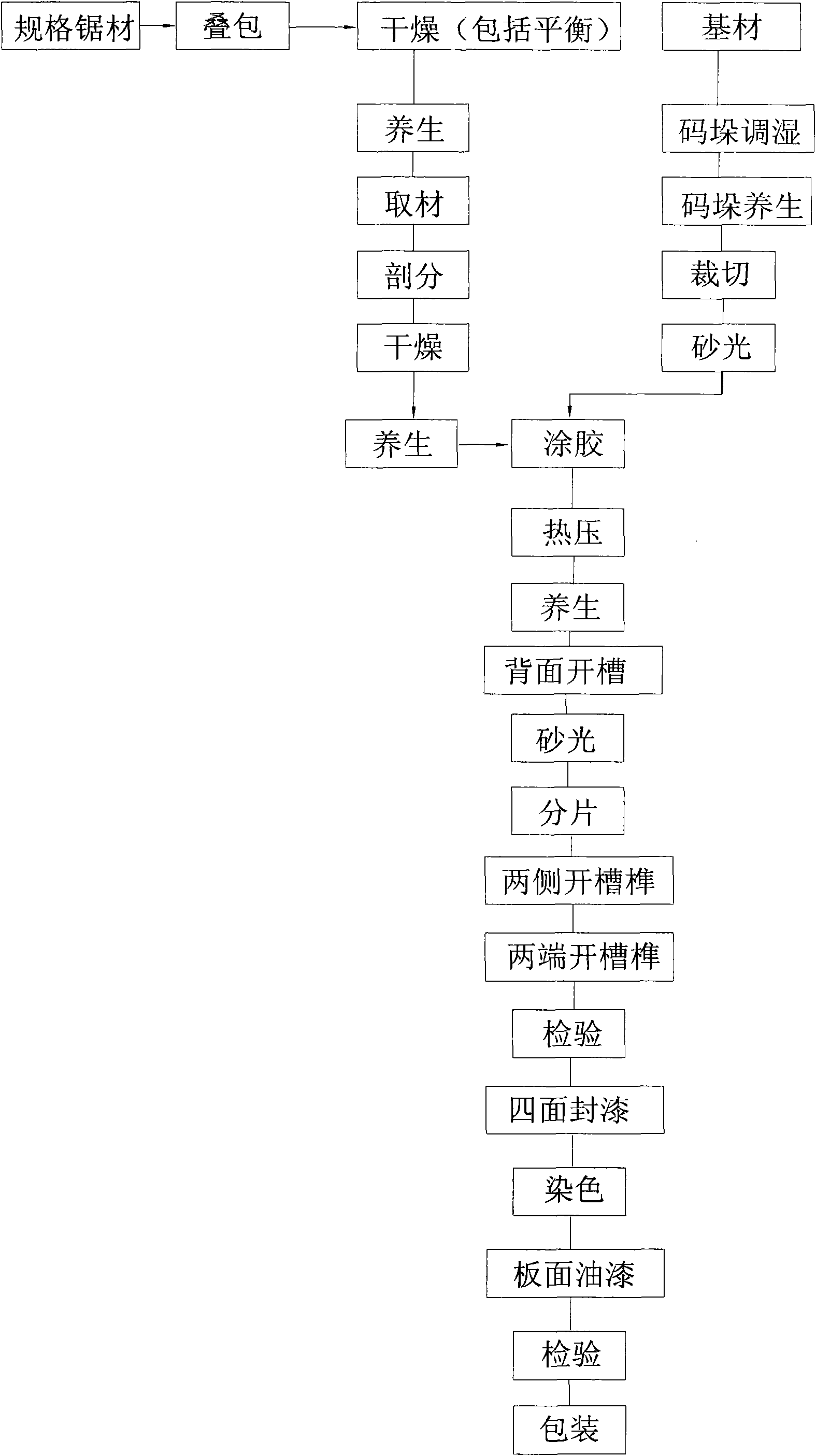

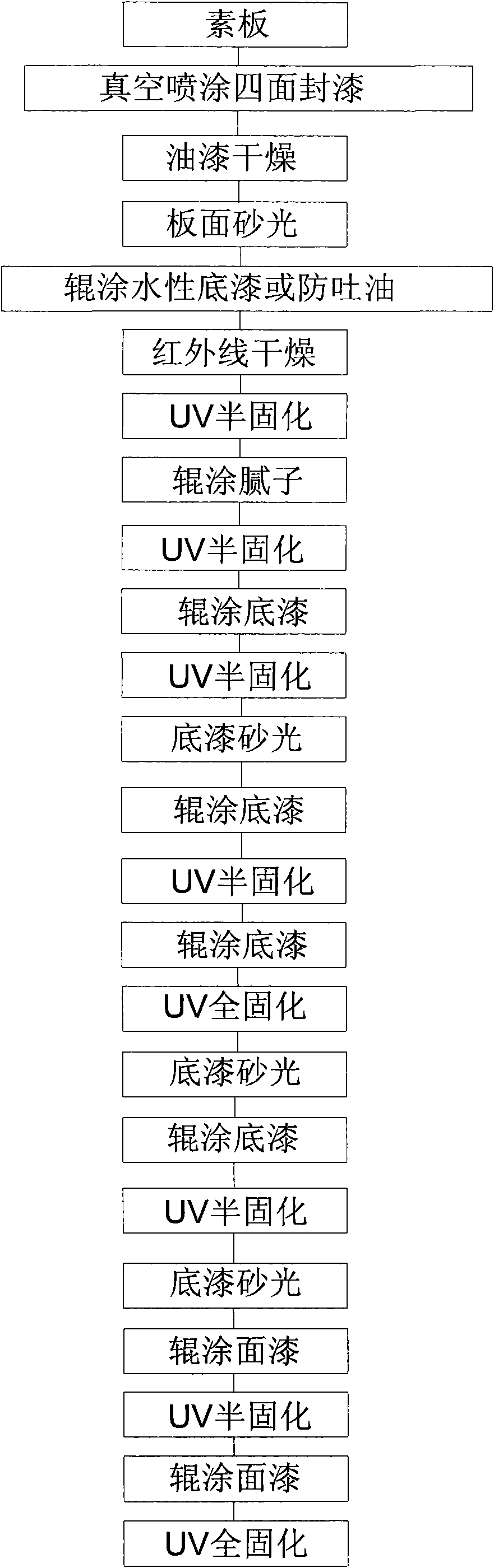

[0023] Such as figure 1 and image 3 Shown, the production method of weather-resistant multi-layer composite wood flooring of the present invention, comprises the following steps:

[0024] (1), the moisture content of the solid wood board with a moisture content > 16% is reduced to 12-16% after the normal drying and balancing and health-preserving procedures;

[0025] (2) After the solid wood board with a moisture content of 12 to 16% is sawed and cut into panels with a thickness of 1 to 4mm, the moisture content of the panels is reduced to 6 to 9% through low-temperature drying and balancing and health preservation procedures, and the moisture content of the panels is reduced. Rate error is controlled within 1-2%;

[0026] (3) The plywood base material with a moisture content of 9 to 14% is dried and balanced at low temperature, and processed to a moisture content of 10 to 8%, and the moisture content error is controlled at 0.5 to 1.5%;

[0027] (4) After cutting, sanding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com