Integrated liquid storage pot and novel zinc-bromine redox flow battery

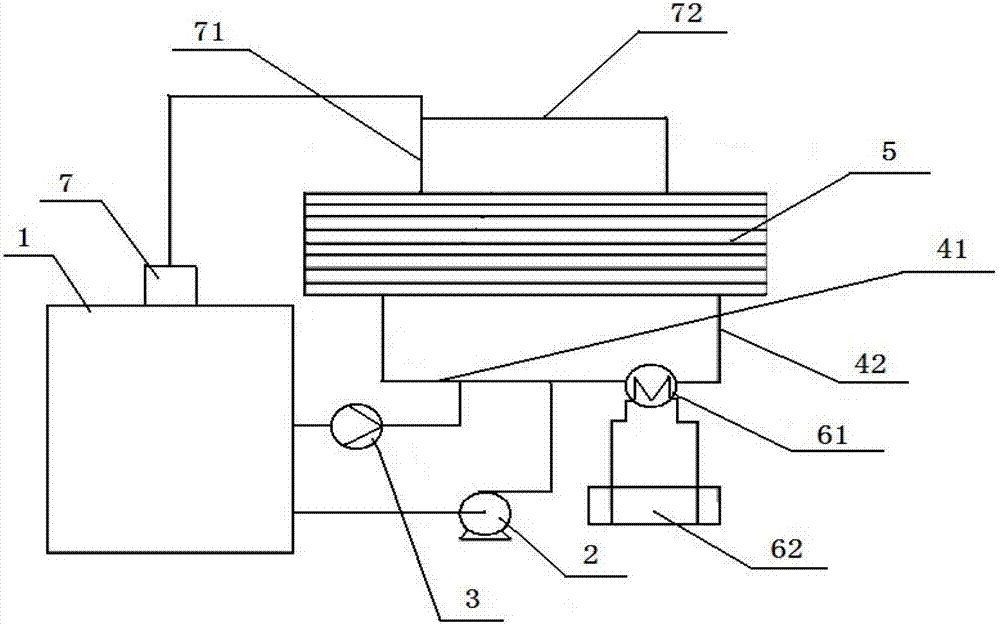

A zinc-bromine flow battery and liquid storage tank technology, applied in fuel cells, fuel cell additives, indirect fuel cells, etc., can solve problems affecting battery performance and life, electrolyte migration, and uneven matching of positive and negative electrolytes and other problems, to achieve the effect of improving energy density, improving performance and service life, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

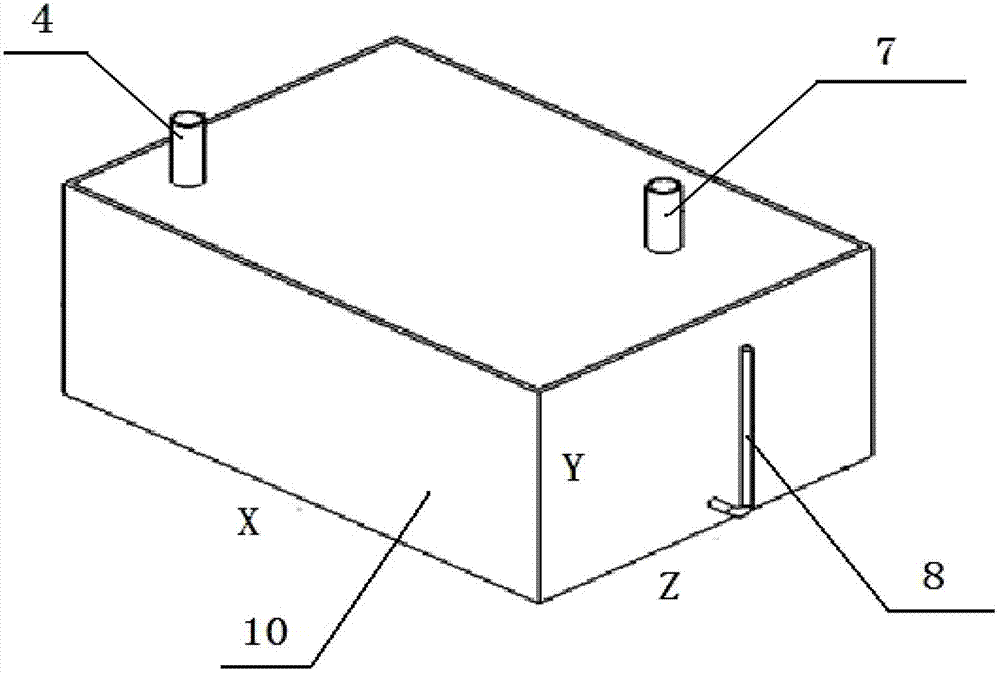

[0051] Embodiment 1: a kind of integrated storage tank, such as figure 2 As shown, it comprises: a tank body 10, a bromine supply pipeline 8, a total return pipe 7 and a liquid supply pipe 4, one end of the bromine supply pipeline 8 runs through the side wall of the tank body 10 and is positioned in the tank body 10, and the total return pipe 7 and one end of the liquid supply pipe 4 pass through the top of the tank body 10 and are located above the bottom of the tank body 10 .

Embodiment 2

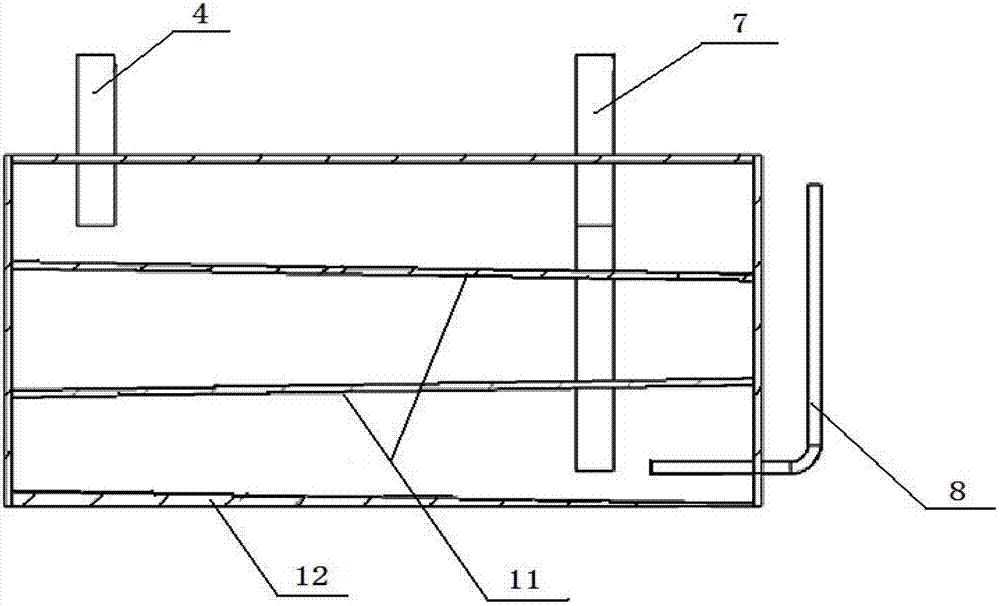

[0052] Embodiment 2: a kind of integrated storage tank, such as figure 2 As shown, it comprises: a tank body 10, a bromine supply pipeline 8, a total return pipe 7 and a liquid supply pipe 4, one end of the bromine supply pipeline 8 runs through the side wall of the tank body 10 and is positioned in the tank body 10, and the total return pipe 7 and one end of the liquid supply pipe 4 pass through the top of the tank body 10 and are located above the bottom of the tank body 10 . The tank body 10 is also provided with a baffle plate 11 and a bottom plate 12 (such as image 3 shown), one end of the bottom plate 12 is connected to the side of the bottom surface of the tank body 10 close to the bromine supply pipeline 8 and the angle between the bottom plate 12 and the bottom surface of the tank body 10 is 5°; 4, one end of the total return pipe 7 runs through the baffle 11 and is located above the bottom plate 12, the angle between the baffle 11 and the horizontal plane is 5°, a...

Embodiment 3

[0053] Embodiment 3: an integrated liquid storage tank, comprising: a tank body 10, a bromine supply pipeline 8, a total return pipe 7 and a liquid supply pipeline 4, one end of the bromine supply pipeline 8 runs through the side wall of the tank body 10 and Located in the tank body 10 , one end of the total return pipe 7 and the liquid supply pipe 4 runs through the top of the tank body 10 and is located above the bottom of the tank body 10 . The tank body 10 is also provided with a baffle plate 11 and a bottom plate 12. One end of the bottom plate 12 is connected to the side of the bottom surface of the tank body 10 close to the bromine supply pipeline 8 and the angle between the bottom plate 12 and the bottom surface of the tank body 10 is 5°. °; the baffle plate 11 is located between the bottom plate 12 and the liquid supply pipe 4, and one end of the total return pipe 7 runs through the baffle plate 11 and is located above the bottom plate 12, and the angle between the baf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com