Novel balloon urethral catheter

A catheter and balloon tube technology, which is applied in the field of thermoplastic material and thermosetting material multi-layer composite balloon catheter, can solve the problem of adhesion and blockage of the balloon filling cavity, inability to empty, and the liquid drainage cavity becomes smaller flow and other problems, to achieve the effect of high strength, small deformation rate, and strong supporting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

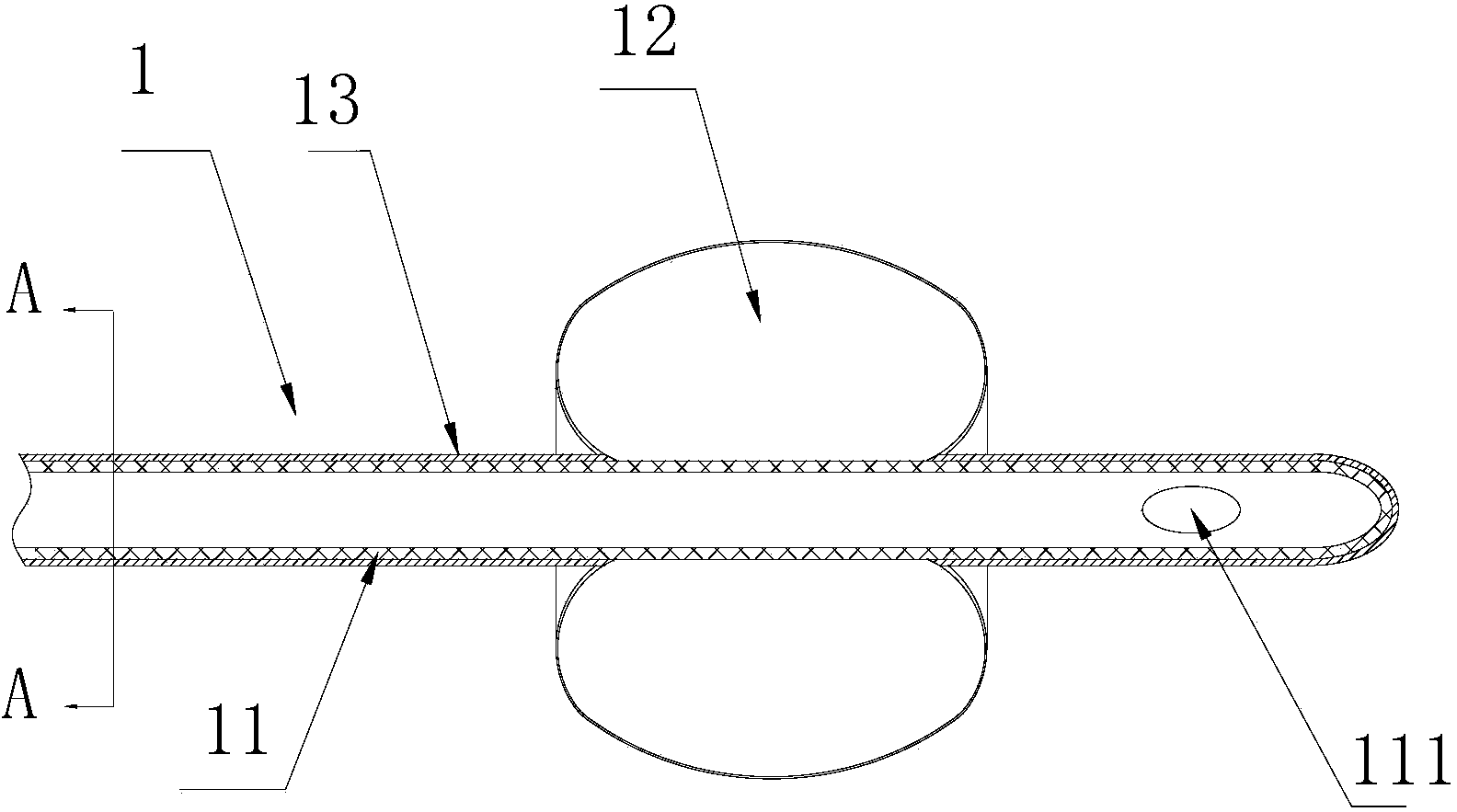

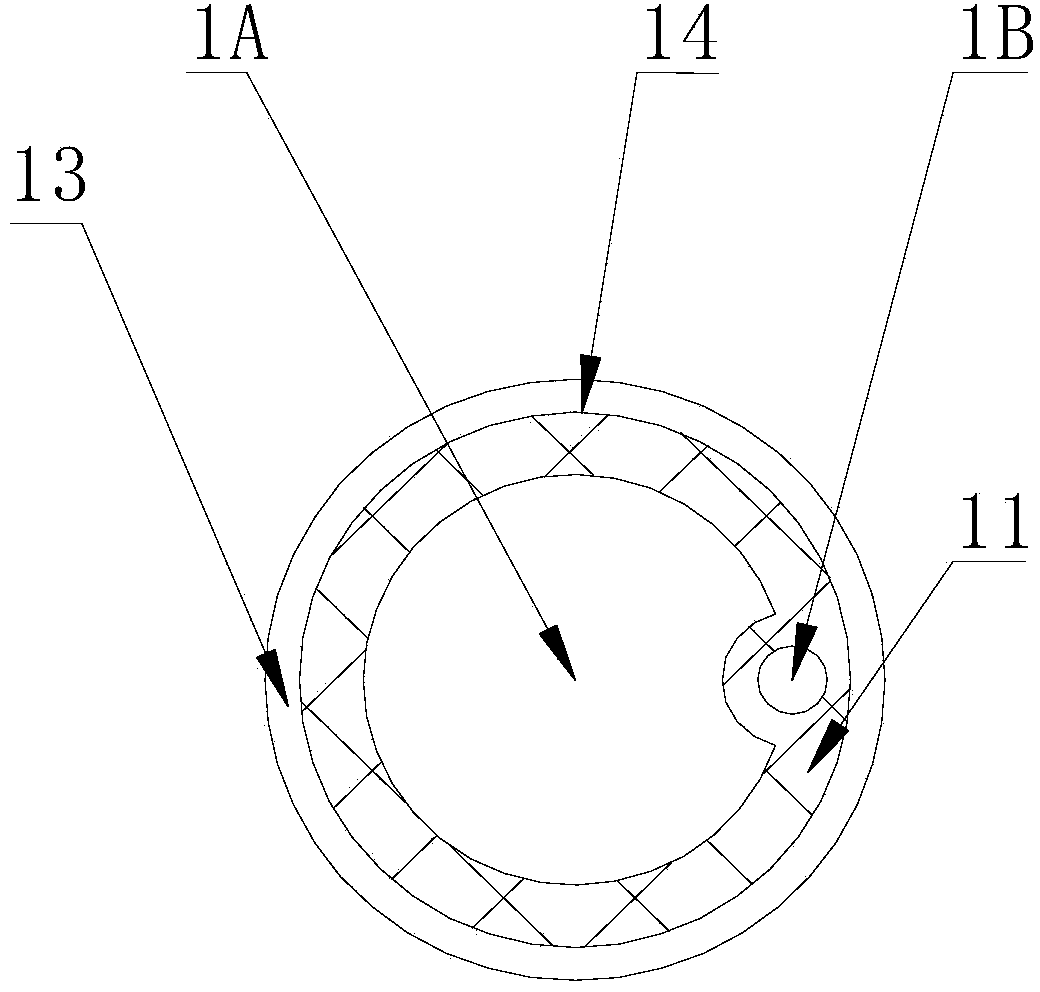

[0031] Such as Figure 2 to Figure 4 As shown, a new type of balloon catheter includes a tube body 1, the tube body 1 is provided with a fluid drainage lumen 1A and a balloon filling lumen 1B, and the tube body 1 includes an inner layer tube 11 , the balloon tube 12 and the outer layer 13, the balloon filling cavity 1B is arranged in the tube wall of the inner layer tube 11 and communicated with the balloon tube 12, the balloon filling cavity 1B is set In the tube wall of the inner tube 11, a liquid inlet hole 111 is provided at the end of the inner tube inserted into the bladder, the outer layer 13 is wrapped on the surface of the inner tube 11, and the balloon The tube 12 is arranged between the inner layer tube 11 and the outer layer 13, more specifically, it is arranged at the tail of the tube body 1, wherein the inner layer tube 11 is a thermoplastic material, and the outer layer 13 is a thermosetting material. In practical application, the tube wall of the inner tube 1...

Embodiment 2

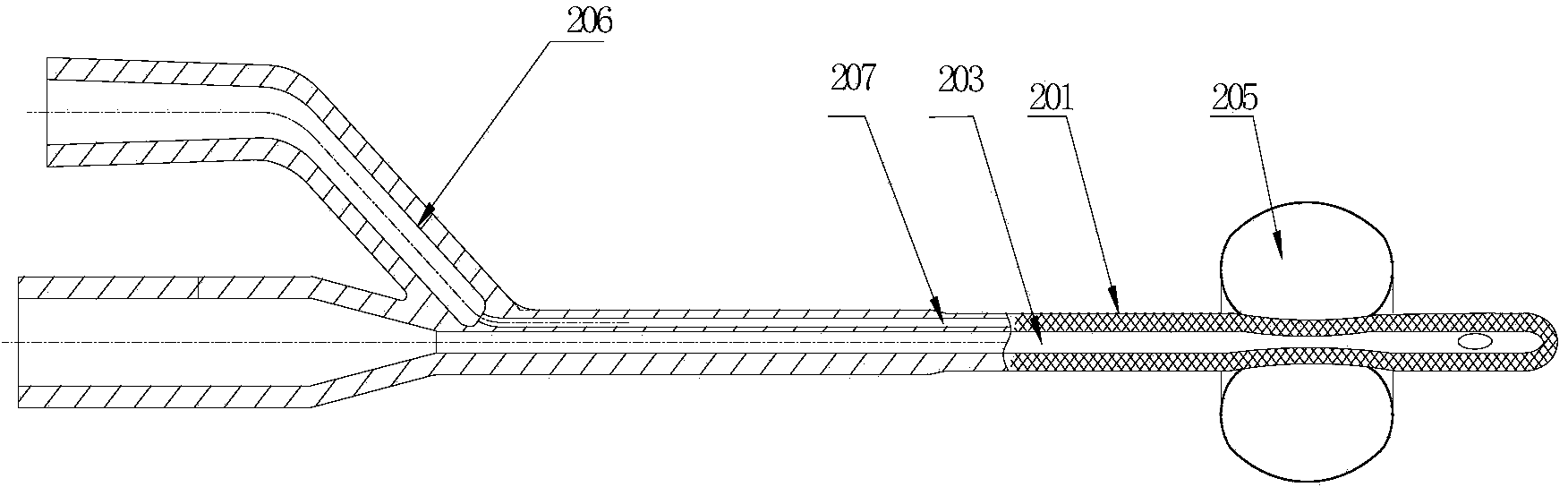

[0044] Such as Figure 5 to Figure 7 As shown, this embodiment is roughly the same as Embodiment 1, except that an inner tube skin 15 composed of one or more layers of thermosetting material is arranged between the inner tube 11 and the outer layer 13. The balloon tube 12 is connected to the inner tube skin 15 . Correspondingly, the manufacturing process is slightly different from that of Example 1. First, the inner tube 11 is prepared by one extrusion, and then the inner tube skin 15 is prepared by dipping in glue after the above-mentioned three methods, and then the balloon tube is sleeved and fixed. 12, and then multiple times of dipping to prepare the outer layer 13, and finally install the joint 16 and siliconize the surface to obtain the finished product.

[0045] The advantage of this arrangement is that the inner tube 11 can be connected with the inner tube skin 15 only through one treatment, without being directly connected with the balloon tube 12. The treatment met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com