Nylon rubber for bushing and preparation method of nylon rubber

A rubber and nylon technology, applied in the field of rubber, can solve the problems of low shock absorption effect and poor torsional fatigue characteristics, and achieve the effects of strong fatigue resistance, reduced deformation rate and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

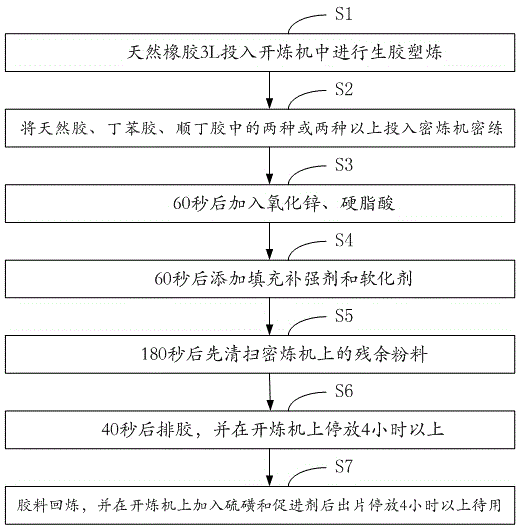

Method used

Image

Examples

Embodiment Construction

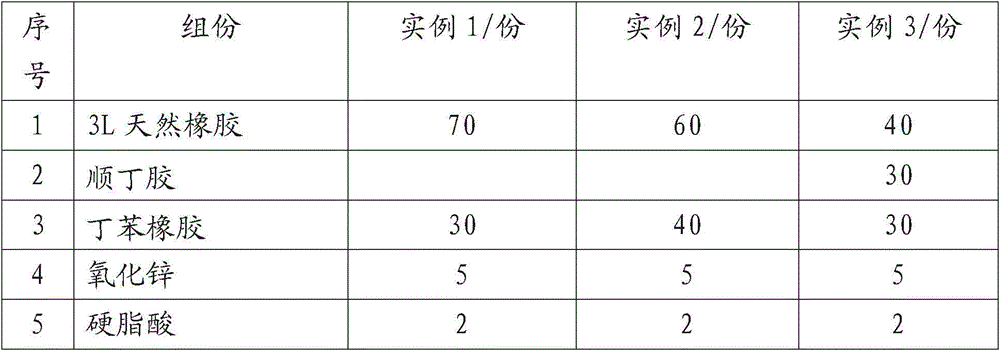

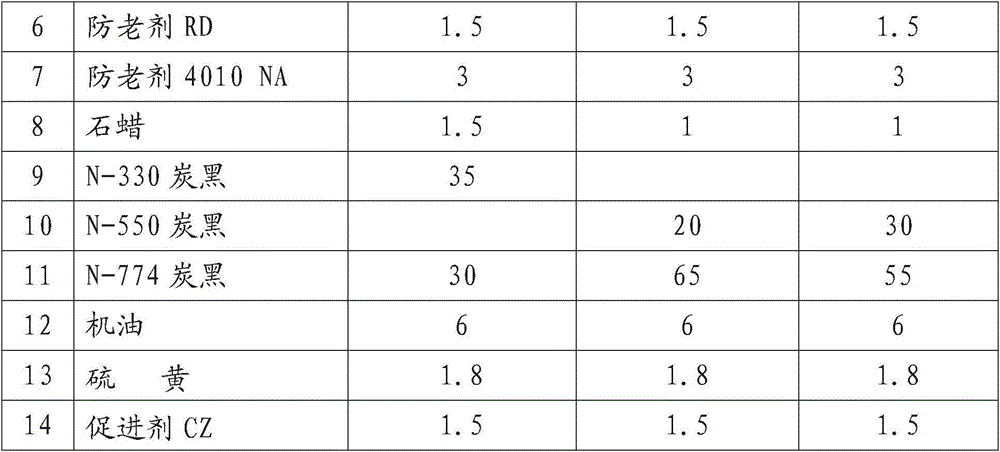

[0023] The nylon rubber used for the bushing provided by the present invention comprises or contains the following components and parts by weight: 100-170 parts of rubber; 4-8 parts of active agent; 1-3 parts of stearic acid; 2 parts of anti-aging agent ~6 parts; 80~12 parts of filling and reinforcing agent; 4~10 parts of softener; 1~2.5 parts of vulcanizing agent; 1~4 parts of accelerator.

[0024] The rubber includes natural rubber and styrene-butadiene rubber, and the ratio of the natural rubber to the styrene-butadiene rubber is 6:2.5.

[0025] The rubber also includes butadiene rubber, and the ratio of the butadiene rubber to the natural rubber is 1.5:6.

[0026] The natural rubber is 3L natural rubber.

[0027] The anti-aging agent is one or a mixture of at least two of the anti-aging agent 4010NA, the anti-aging agent 4020 and the anti-aging agent RD.

[0028] The filling reinforcing agent is one or more mixtures of N330 carbon black, N550 carbon black and N754 carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com