Steel arch frame closure device

A technology of steel arches and telescopic devices, applied in the field of steel arches, which can solve problems such as the inability to automatically adjust the arc length of steel arches, and achieve the effects of convenient and quick adjustment, good versatility, and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

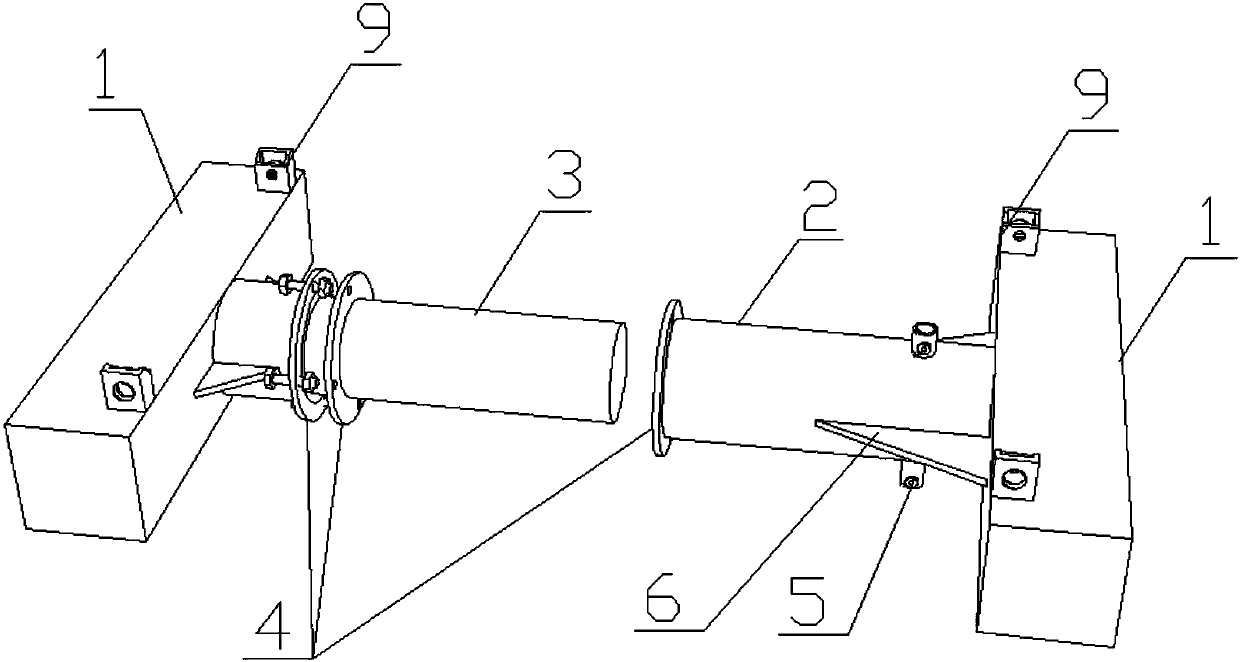

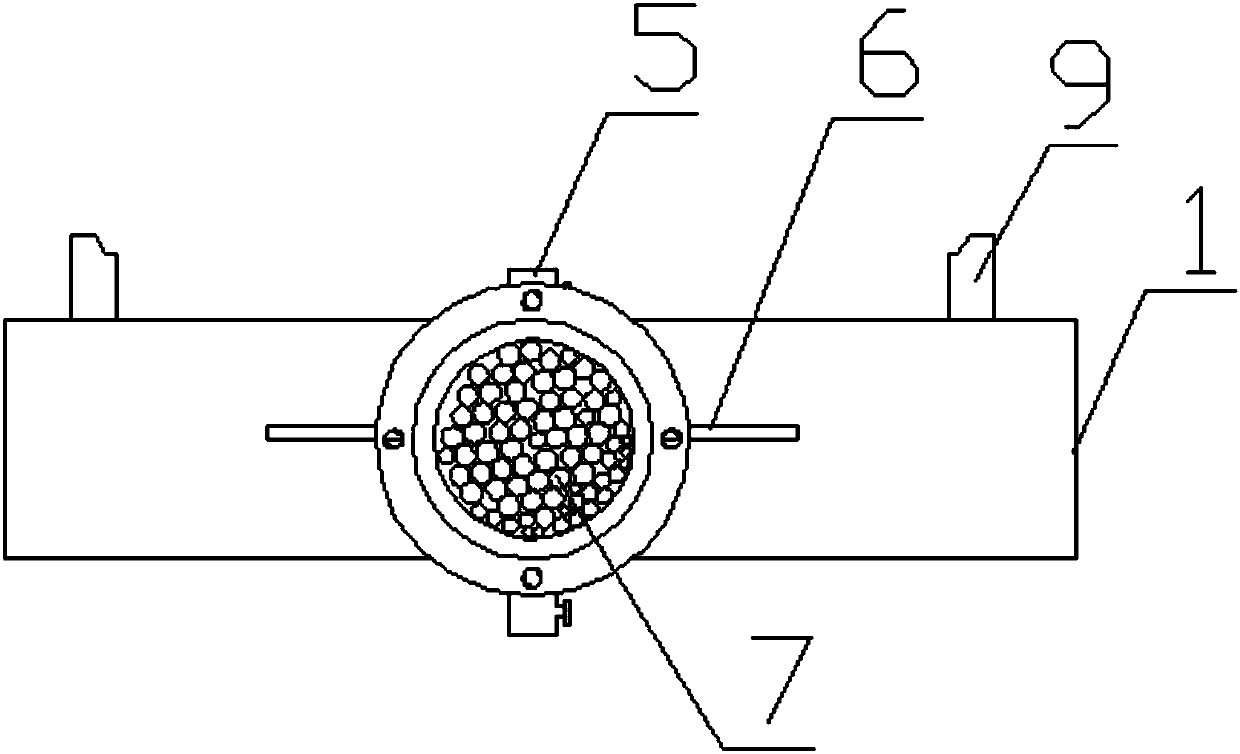

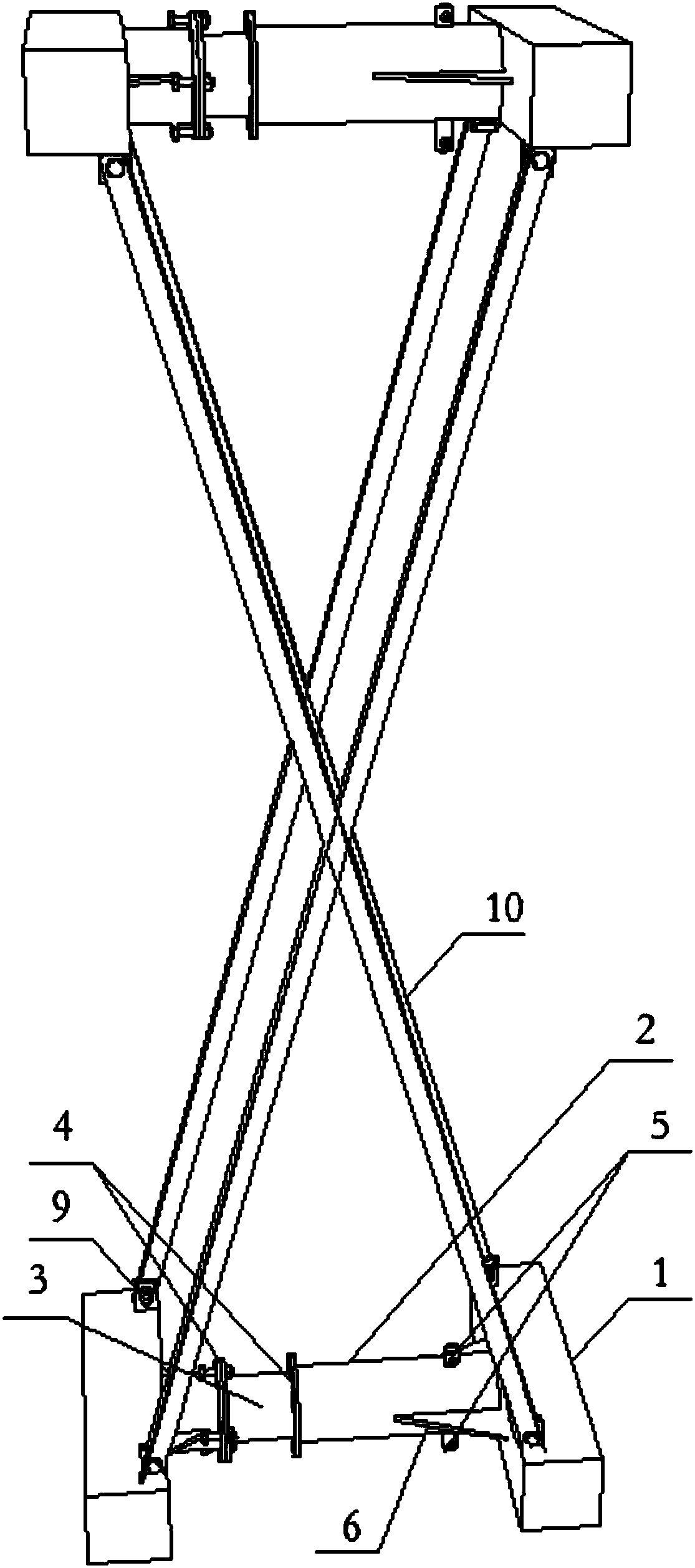

[0028] A steel arch closing device, such as Figure 1 to Figure 3 As shown, it includes an upper chord and a lower chord, and a support 10 is arranged between the upper chord and the lower chord, and a telescopic device for adjusting the length of the upper chord and the lower chord. The telescopic device adopts a flexible telescopic device to realize the stroke adjustment of the steel arch closing device. The flexible telescopic device includes a cylinder body 2 and a telescopic rod 3. The telescopic rod 3 extends into the cylinder body 2 and forms a space for accommodating the steel ball sand 7 with the inner wall of the cylinder body 2. The telescopic rod 3 moves axially along the cylinder body 2 to extrude the steel ball sand 7. Realize telescopic adjustment. Through the mutual cooperation of the steel ball sand 7, the telescopic rod 3 and the cylinder body 2, the automatic shrinkage of the flexible telescopic device can be realized to adjust the stroke of the steel arch c...

Embodiment 2

[0042] A steel arch closing device, such as Figure 5 As shown, it includes the upper chord and the lower chord, and there is a support between the upper chord and the lower chord, and two sets of telescopic devices for adjusting the length of the upper chord and / or the lower chord. The telescopic device adopts a flexible telescopic device to realize the stroke of the steel arch closing device adjust. The flexible telescopic device includes a cylinder body and a telescopic rod. The telescopic rod extends into the cylinder body and forms a space for accommodating the steel ball sand with the wall of the cylinder body. The telescopic rod moves along the axial direction of the cylinder body to squeeze the steel ball sand to realize telescopic adjustment. The automatic contraction of the flexible telescopic device can be realized through the mutual cooperation of the steel ball sand, the telescopic rod and the cylinder to adjust the stroke length of the steel arch closing device, ...

Embodiment 3、 Embodiment 4

[0051] A closing segment, using the steel arch closing device in Embodiment 1 or Embodiment 2 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com