A kind of animal colloid protein compound apocynum cellulose fiber and preparation method thereof

A technology of cellulose fibers and colloidal proteins, which is applied in the fields of artificial filaments made of cellulose derivatives, fiber chemical characteristics, rayon manufacturing, etc., can solve the problem of high elongation at breakage of fibers in dry and wet conditions, antibacterial effects of Candida albicans Low efficiency, no problems such as releasing infrared rays, and achieve good insect repellent, good anti-radiation, and good antibacterial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

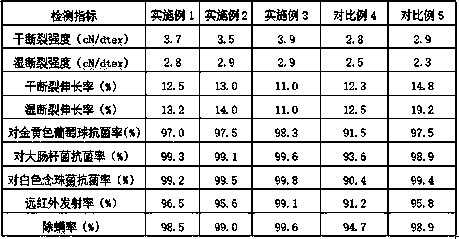

Examples

Embodiment 1

[0060] Embodiment 1 A kind of preparation method of animal colloid protein compound apocynum cellulose fiber, comprises the following steps:

[0061] One, prepare apocynum viscose liquid

[0062] (1) Use a pulverizer to crush the apocynum pulp into a pulp porridge with a concentration of 400g / L;

[0063] (2) Cellulose activation: add hydrogen peroxide to the prepared apocynum pulp porridge, and react for 30-50 minutes after the porridge is heated; the concentration of hydrogen peroxide in the apocynum pulp porridge is 20g / L; the temperature of the porridge is raised to 50°C ;

[0064] During the cellulose activation process, activator dz-01 was added; the concentration of activator in the porridge was 1g / L; activator dz-01 was produced by Zibo Liante Bioenzyme Co., Ltd.;

[0065] (3) One-time pressing: the pressing temperature is 26°C, and the pressing multiple is 1.6 times;

[0066] (4) Alkali impregnation: impregnate Apocynum pulp after one pressing in NaOH impregnating l...

Embodiment 2

[0088] Embodiment 2 A kind of preparation method of animal colloid protein compound apocynum cellulose fiber, comprises the following steps:

[0089] One, prepare apocynum viscose liquid

[0090] (1) Use a pulverizer to crush the apocynum pulp into a pulp porridge with a concentration of 450 g / L;

[0091] (2) Cellulose activation: add hydrogen peroxide to the prepared apocynum pulp porridge, and react for 35 minutes after the porridge is heated; the concentration of hydrogen peroxide in the apocynum pulp porridge is 24g / L; Add activator dz-01 during the activation process; the concentration of activator in the porridge is 3g / L;

[0092] (3) One-time pressing: the pressing temperature is 28°C, and the pressing multiple is 1.9 times;

[0093] (4) Alkali impregnation: impregnate Apocynum pulp in a NaOH impregnation solution with a concentration of 100-140g / l after one pressing, the impregnation temperature is 25°C, the impregnation time is 35 minutes, and the concentration of h...

Embodiment 3

[0116] Embodiment 3 A kind of preparation method of animal colloid protein composite apocynum cellulose fiber, comprises the following steps:

[0117] One, prepare apocynum viscose liquid

[0118] (1) Use a pulverizer to crush the apocynum pulp into a pulp porridge with a concentration of 450 g / L;

[0119] (2) Cellulose activation: add hydrogen peroxide to the prepared apocynum pulp porridge, and react for 45 minutes after the porridge is heated; the concentration of hydrogen peroxide in the apocynum pulp porridge is 30g / L; During the activation process of the element, add the activator dz-01; the concentration of the activator in the slurry is 2g / L;

[0120] (3) One-time pressing: the pressing temperature is 32°C, and the pressing multiple is 2.3 times;

[0121] (4) Alkali impregnation: impregnate Apocynum pulp after one pressing in NaOH impregnation solution with a concentration of 140g / l, the impregnation temperature is 30°C, the impregnation time is 50 minutes, and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com