A stainless steel air duct processing and welding equipment

A welding equipment, stainless steel technology, applied in the field of stainless steel air duct processing and welding equipment, can solve the problems of reducing welding efficiency, large air duct gravity, increasing welding difficulty, etc., to improve welding quality, high force uniformity, and improved The effect of the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

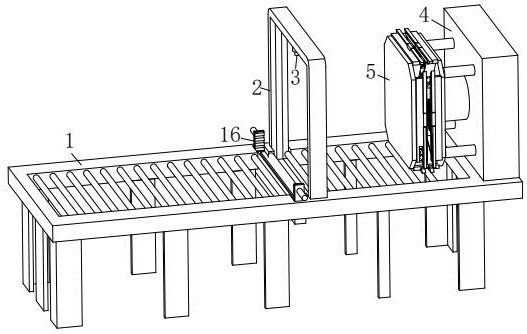

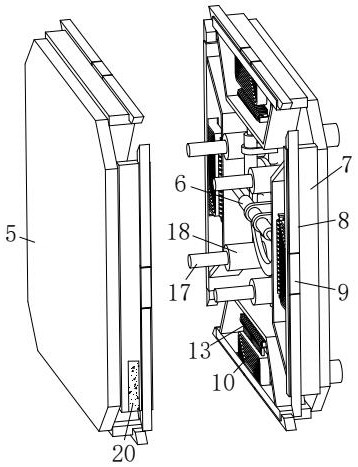

[0025] Below in conjunction with the accompanying drawings in the embodiments of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely

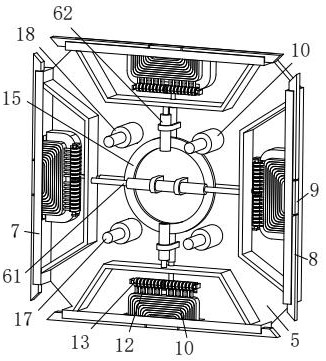

[0030] The transmission drive assembly 14 includes an interval limit groove 141 and a transmission drive block 142 that cooperate with each other, and the two are respectively

[0034] Referring to FIG. 3, the driving part 6 includes a transverse two-way cylinder 61 and a vertical one-way cylinder 62, both of which are connected in phase

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com