Deformation-preventing device for evanescent mode ductile iron pipe fitting bell mouth

A ductile iron tube and lost foam technology, which is used in casting molding equipment, molds, cores, etc., can solve the problems that the size can only be fixed, and the sand ring cannot be well fixed on the end face of the socket, so as to increase the arc shape. The area and the socket size are stable and not deformed, and the effect of improving the anti-deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0023] In the present invention, unless stated otherwise, the used orientation words such as "up, down, left, right" usually refer to figure 1 Up and down and left and right are shown. "Inner and outer" refer to the inner and outer on the specific outline. "Far and near" refer to far and near relative to a certain component.

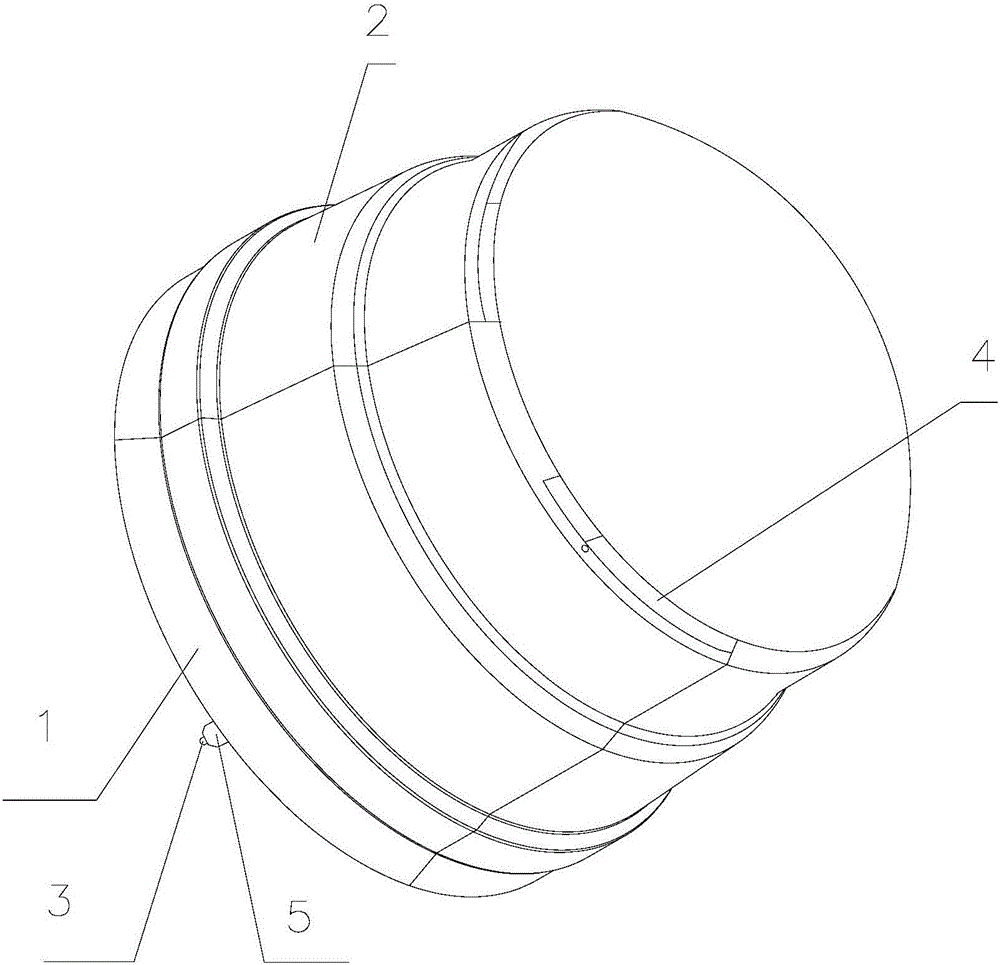

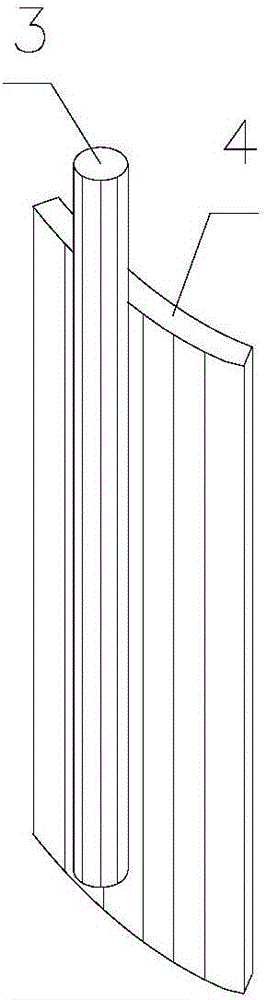

[0024] The present invention provides an anti-deformation device for the socket 2 of a lost foam ductile iron pipe fitting. The socket 2 of the lost foam ductile iron pipe fitting is in the shape of a circular column. The anti-deformation device for the socket 2 of the lost foam ductile iron pipe fitting includes:

[0025] The rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com