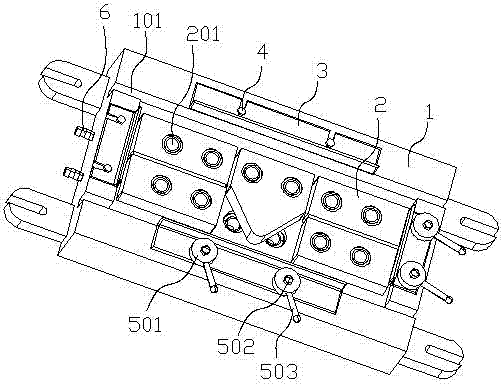

A fixture for milling of thin-walled frame parts

A kind of milling processing and frame-like technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve problems such as fixture deformation, and achieve the effects of preventing air leakage, good deformation prevention, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] Milling the 500 (length) × 230 (width) × 50 (thickness) mm rough, it is required to process double-sided thin-walled frame parts, the processing method is as follows:

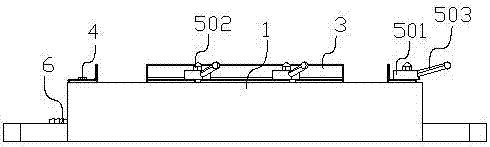

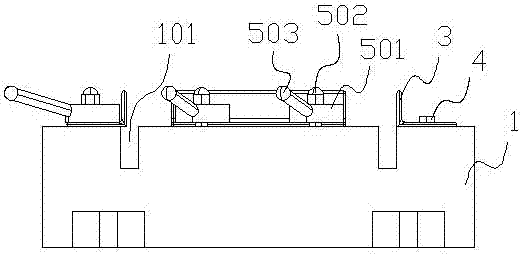

[0051] The first step is to install the fixture on the milling machine and connect the pipeline of the vacuum pump; install the sealing ring in the air hole 102 and the sealing groove 202 of the movable block 2, and then insert the lower end of the corresponding movable block 2 into the upper end of the fixture. Finally, if there is The channel that is not installed with a loose block is sealed with a cover;

[0052] The second step is to place the blank on the movable block 2, pull the adjustment handle 503, and then push the movable baffle through the adjustment cam 501, and then clamp the blank;

[0053] The third step is to turn on the vacuum pump for milling;

[0054] The fourth step, after the milling process is completed, turn off the vacuum pump, loosen the positioning device 5, remove the parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com