Multi-nozzle oppositely-arranged type gasifier nozzle mounting flange installing and welding method

A technology for installing flanges and gasifiers, which is applied in the field of flange welding and multi-nozzle opposed gasifier burners. Large deviation and other problems, to achieve the effect of good anti-deformation effect, good quality, reasonable form and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

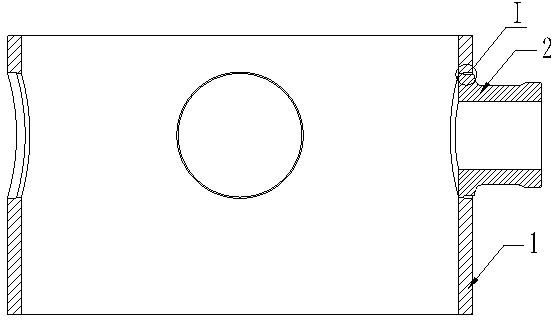

[0046] The product selected in this example is a multi-nozzle opposed coal-water slurry gasifier, and its shell and burner installation flange specifications are as follows:

[0047] Gasifier: the inner diameter of the shell is φ3600mm, the wall thickness is 112mm, and the length is about 25000mm;

[0048] Burner mounting flange: inner diameter φ560mm, maximum thickness 154mm, flange height 683.8mm;

[0049] The outer diameter of flange and housing assembly is φ1020mm.

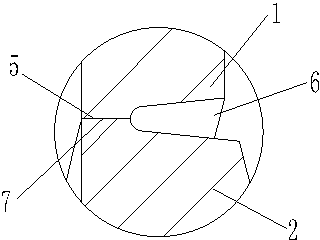

[0050] The assembly accuracy requirements of the burner mounting flange are as follows:

[0051] ① The four burner installation flanges are required to be evenly distributed at 90° on the same plane, and the plane deviation is not greater than 2mm;

[0052] ② The deviation of the coaxiality of each two relative burner installation flanges is not greater than 3mm;

[0053] ③ The deviation of the perpendicularity between the flange surface and its axis after welding is not greater than 1mm;

[0054] ④ The pe...

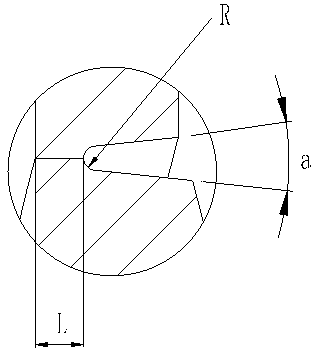

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com