Anti-deformation machine cover edge rolling blank mold

An anti-deformation and hemming technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as deformation, and achieve the effects of ease of use, enhanced work stability, and stable mold effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

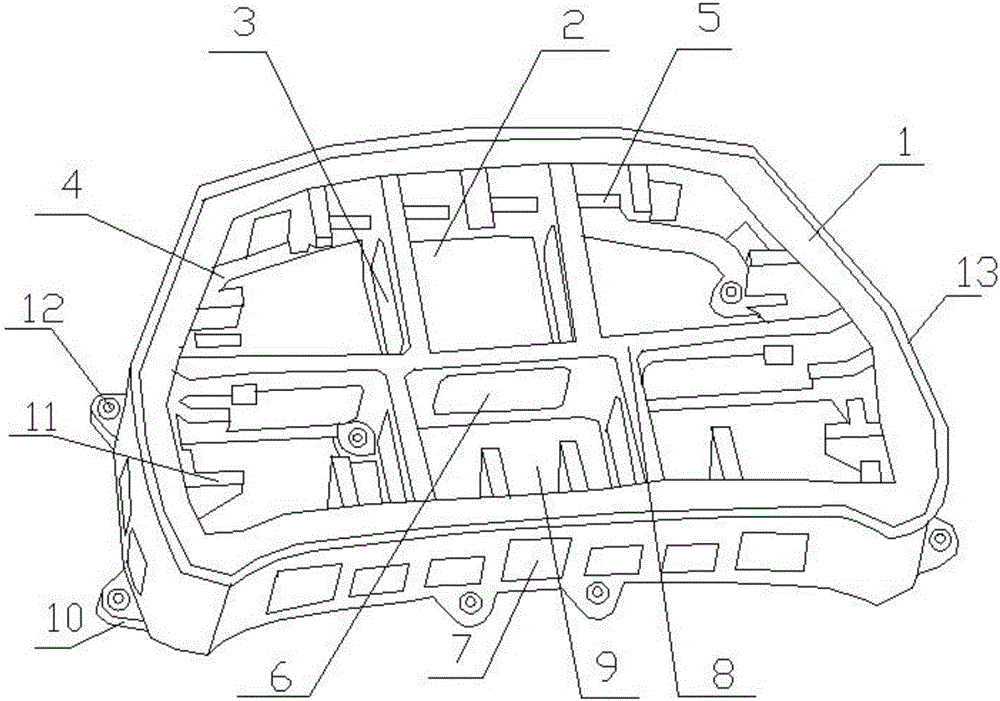

[0018] like figure 1 As shown, the present invention provides an anti-deformation machine cover piping membrane, including a body 1, the side of the body 1 is provided with an anti-deformation steel 13, the inside of the body 1 is provided with a partition 8, and the partition 8. There are three front mold chambers 2 arranged on the upper part of the interior. The adjacent places of the front mold chambers 2 are provided with mold outlets 3. The lower part of the partition 8 is provided with three rear mold chambers. 10. A mold outlet 3 is provided adjacent to the rear mold cavity 10 , and mold clips 5 are provided on both sides of the mold outlet 3 .

[0019] Further, the edges of the front mold cavity 2 and the rear mold cavity 10 are provided with anti-deformation fixing parts 4 , and mold clamping blocks 11 are arranged on the upper part of the anti-deformation fixing parts 4 . Wherein, the anti-deformation fixing part 4 is used for preventing deformation inside the mould...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com