Assembly type novel composite plate

A composite board and assembly technology, which is applied to layered products, chemical instruments and methods, metal layered products, etc. It has the advantages of convenient production and processing, strong physical stability and good anti-deformation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

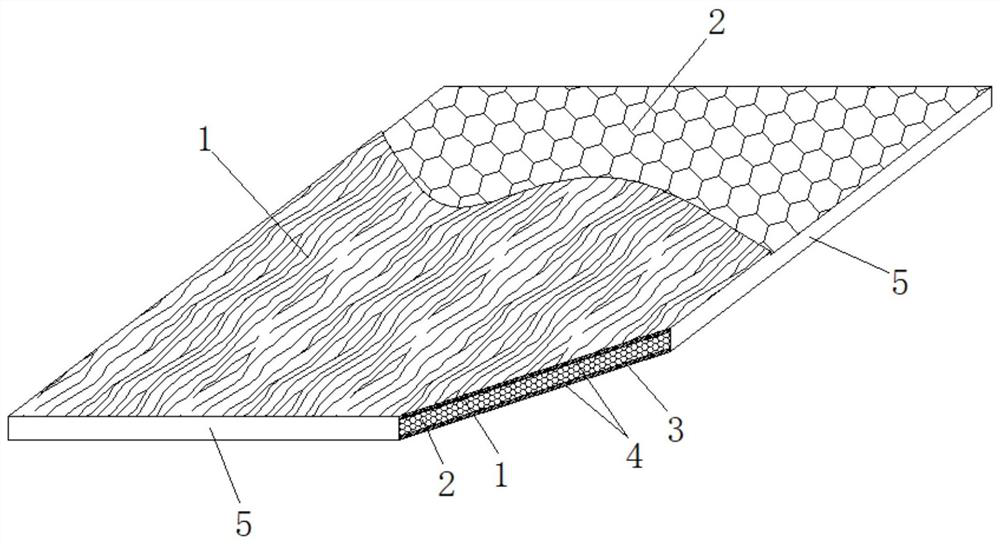

[0030] see figure 1 , the figure shows an assembled new composite panel provided by Embodiment 1 of the present invention, which includes a first original wood board 1, which is arranged on the top layer; a honeycomb board 2, which is arranged on the middle layer; a second original wood board 3 , which is arranged at the bottom; between the first original wood board 1 and the honeycomb board 2, between the honeycomb board 2 and the second original wood board 3 with special glue 4 bonding; the honeycomb board 2 is an aluminum honeycomb board; the first original wood board 1 Identical to the thickness of the second log board 3, and the thickness of the honeycomb board 2 is greater than the thickness of the first log board 1 and the second log board 3; The outside of the second log board 3 .

[0031] A new type of assembled composite board provided in this embodiment mainly includes a first log board 1, a honeycomb board 2 and a second log board 3 arranged sequentially from top ...

Embodiment 2

[0037] see figure 1 , the figure shows an assembled new composite board provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the first log board 1 And the thickness of the second log board 3 is 3mm; the thickness of the honeycomb board 2 is 15mm; Through the setting of the above structure, the stability and strength of the whole board can be guaranteed, and the edge banding 5 helps to beautify the entire appearance structure, and at the same time, the edge banding effect is better.

Embodiment 3

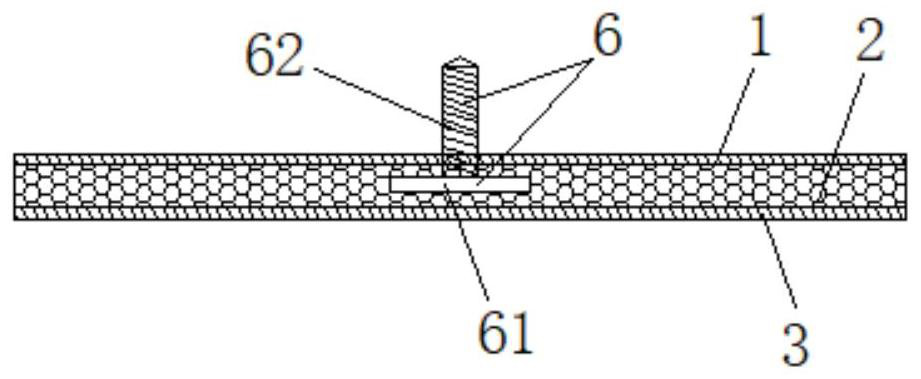

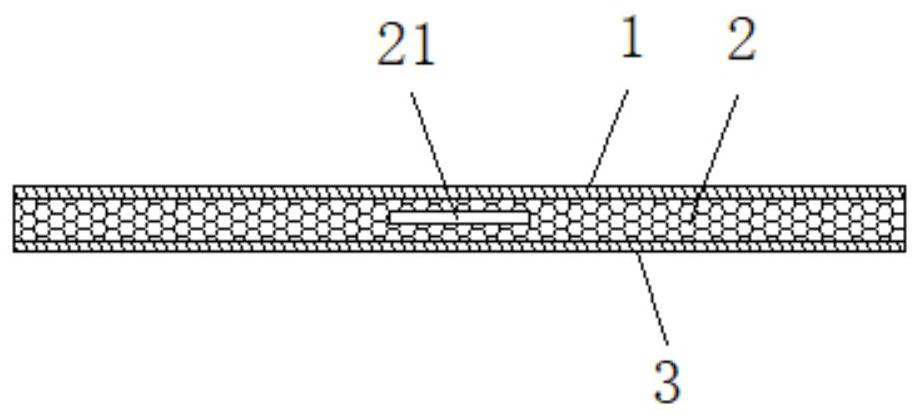

[0039] see Figure 2 to Figure 4 , the figure shows an assembled new composite board provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the first log board 1 There is a pre-embedded connector 6 for installing the hinge, and the pre-embedded connector 6 is located on one side of the first log board 1; the honeycomb panel 2 is provided with a mounting groove 21, and the bottom of the pre-embedded connector 6 is set on the installation slot 21. Through the setting of the above structure and the setting of the pre-embedded connector 6, the installation is quicker and more convenient, and the assembly efficiency is improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com