Glaze chemical polishing fluid

A chemical polishing and glazed technology, which is applied in the field of polishing liquid and chemical polishing liquid, can solve the problems that the performance of polishing powder is difficult to be stably controlled, and the particle size and distribution of polishing powder and abrasive can not be strictly controlled, so as to achieve good polishing effect, enhanced stability, The effect of tight particle arrangement and distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

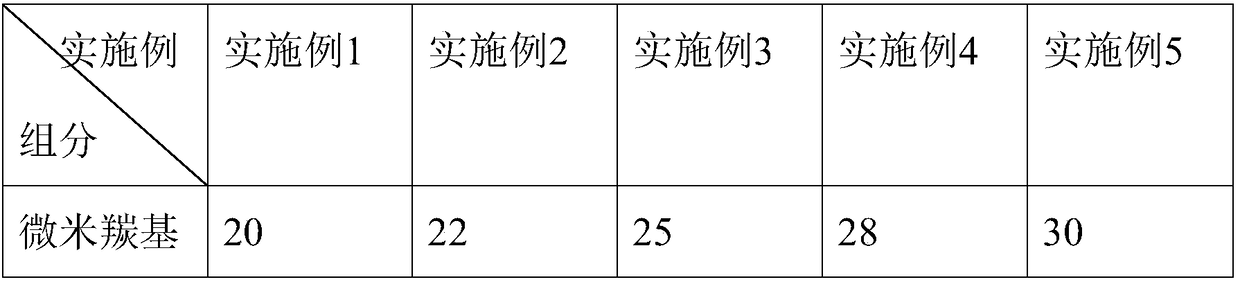

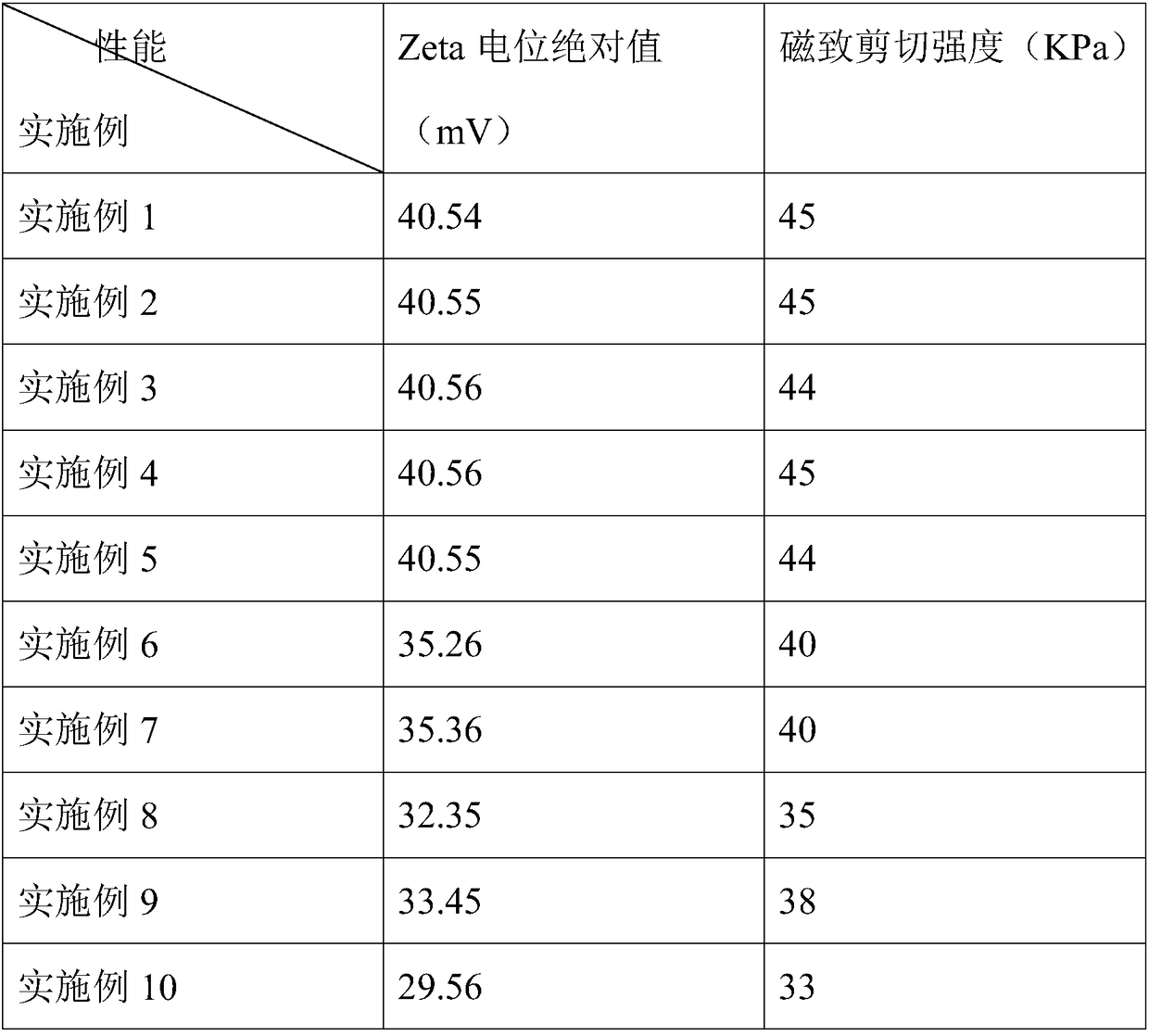

Embodiment 1

[0030] Ultrasonic dispersion: According to the components in Example 1 of Table 1, the polishing powder is dispersed in deionized water with high-power ultrasonic method to obtain a slurry; the polishing powder includes the following components in mass percentage: 10% Ce 1-x Ti x o 2 , 10% microcrystalline frosted, the balance is silicon dioxide; the Ce 1-x Ti x o 2 The preparation method comprises the following steps: in Ce(NO 3 ) 3 Add Ti(SO 4 ) 2 , after stirring in a constant temperature water bath, add H 2 o 2 and NH 3 .H 2 O, adjust the pH to 9 and then react for 2 hours. After suction filtration and washing, use a low-speed stirring ball mill to grind, and introduce a high-speed horizontal ball mill to carry out ultrafine treatment and then spray-dry to obtain; the Ce 1-x Ti x o 2 Ce modified by N-lauroyl ethylenediamine triacetic acid 1-x Ti x o 2 , the modification process specifically includes the following steps: adding Ce to N-lauroyl ethylenediamin...

Embodiment 2

[0033] Ultrasonic dispersion: According to the components in Example 2 of Table 1, the polishing powder is dispersed in deionized water with high-power ultrasonic method to obtain a slurry; the polishing powder includes the following components in mass percentage: 12% Ce 1-x Ti x o 2 , 12% microcrystalline frosted, the balance is silicon dioxide; the Ce 1-x Ti x o 2 The preparation method comprises the following steps: in Ce(NO 3 ) 3 Add Ti(SO 4 ) 2 , after stirring in a constant temperature water bath, add H 2 o 2 and NH 3 .H 2 O, adjust the pH to 9.2 and then react for 2.2 hours. After suction filtration and washing, use a low-speed stirring ball mill to grind, and introduce a high-speed horizontal ball mill to carry out ultrafine treatment and then spray-dry to obtain; the Ce 1-x Ti x o 2 Ce modified by N-lauroyl ethylenediamine triacetic acid 1-x Ti x o 2 , the modification process specifically includes the following steps: adding Ce to N-lauroyl ethylenedi...

Embodiment 3

[0036] Ultrasonic dispersion: According to the components in Example 3 of Table 1, the polishing powder is dispersed in deionized water with a high-power ultrasonic method to obtain a slurry; the polishing powder includes the following components in mass percentage: 15% Ce 1-x Ti x o 2 , 15% microcrystalline frosted, the balance is silicon dioxide; the Ce 1-x Ti x o 2 The preparation method comprises the following steps: in Ce(NO 3 ) 3 Add Ti(SO 4 ) 2 , after stirring in a constant temperature water bath, add H 2 o 2 and NH 3 .H 2 O, adjust the pH to 9.5 and then react for 2.5 hours. After suction filtration and washing, use a low-speed stirring ball mill to grind, and introduce a high-speed horizontal ball mill to carry out ultrafine treatment and spray drying to obtain; the Ce 1-x Ti x o 2 Ce modified by N-lauroyl ethylenediamine triacetic acid 1-x Ti x o 2 , the modification process specifically includes the following steps: adding Ce to N-lauroyl ethylenedi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com