A kind of round bamboo molding board and preparation method thereof

A technology of forming board and round bamboo, which is applied in the direction of manufacturing tools, joining of wooden veneers, wood processing utensils, etc., can solve the problems of the inferior use of moso bamboo and wood, the high cost of use and promotion, and the low utilization rate of moso bamboo. Achieve strong physical stability, improve quality and service life, and reduce transportation and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

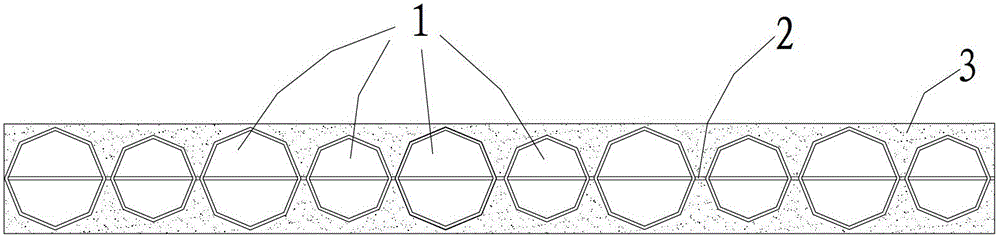

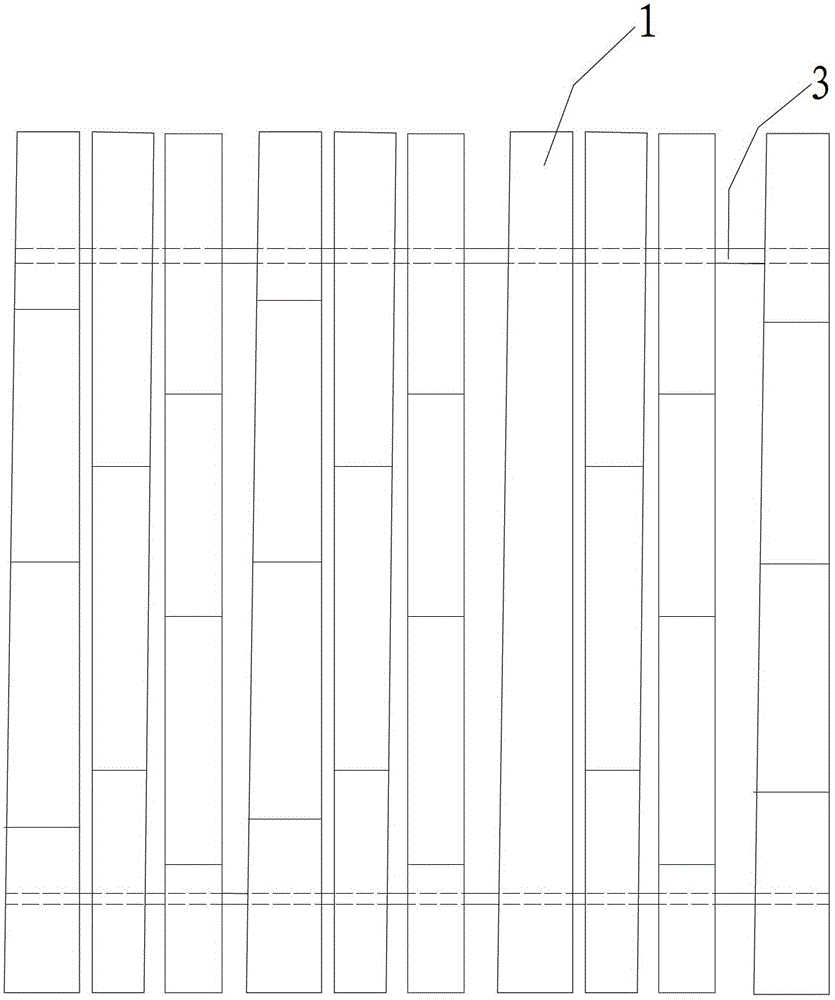

[0021] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

[0022] The round bamboo used in the round bamboo forming board of the present invention is the natural moso bamboo that has not removed bamboo green and bamboo yellow, i.e. green bamboo, and adopting green bamboo to prepare the round bamboo forming board of the present invention can maximize the toughest part of moso bamboo on the one hand, It has strong physical stability; on the other hand, green bamboo will be slightly deformed under hot pressing, unlike dry bamboo, which will be broken when pressed.

[0023] The production process of the round bamboo forming board of the present invention includes blanking, opening up bamboo joints, drilling holes, connecting bamboo sticks, dipping, drying, hot pressing, etc., and finally manufacturing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com