Anti-deformation supporting device for assembling and welding of thin-wall pipes

A support device and anti-deformation technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve problems such as deformation, achieve the effects of preventing deformation, low manufacturing cost, and easy to be widely used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

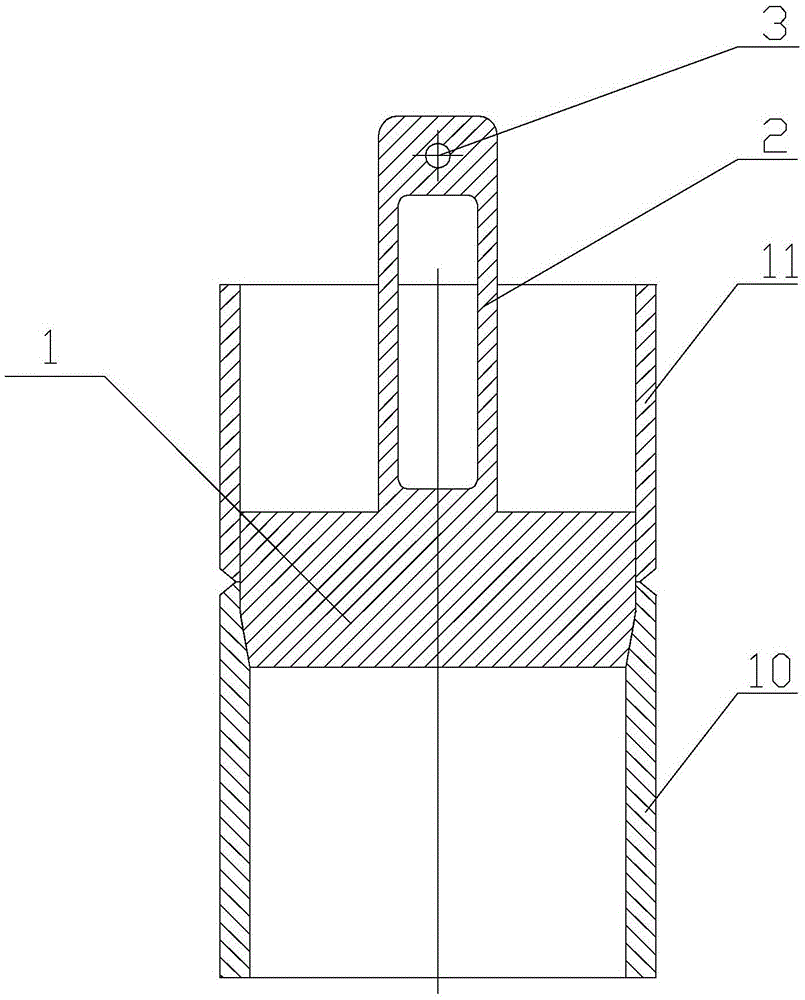

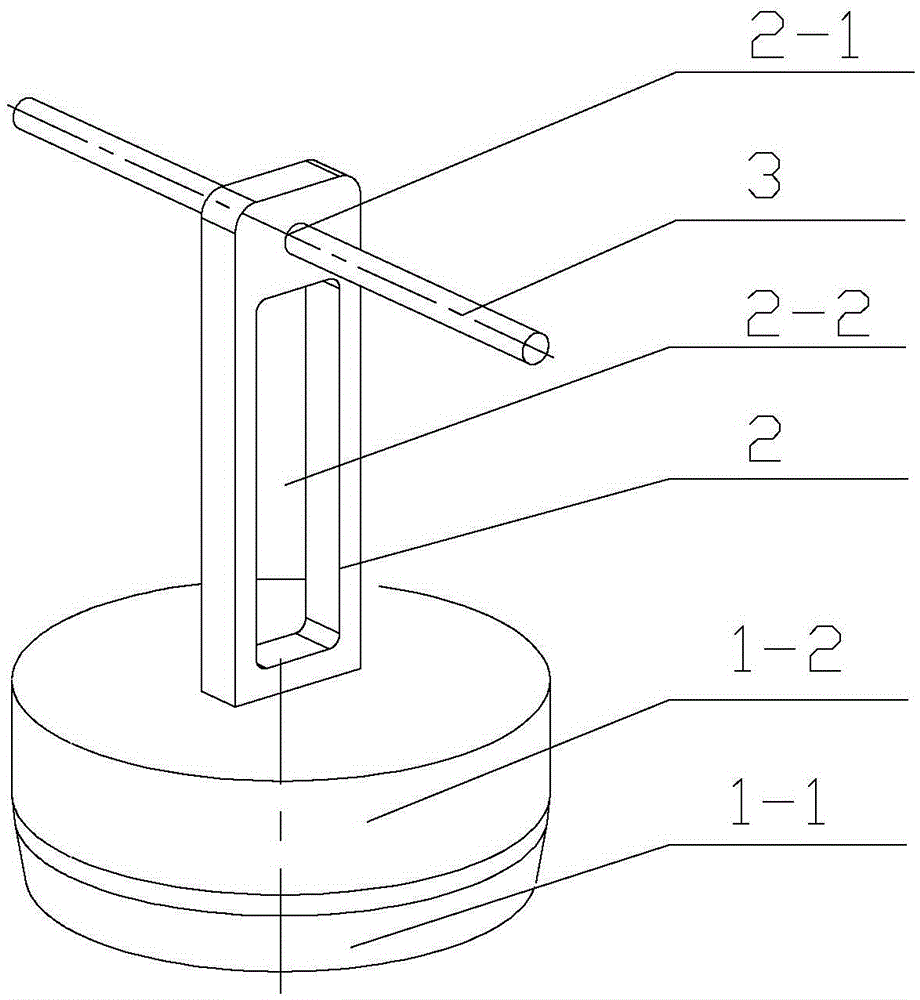

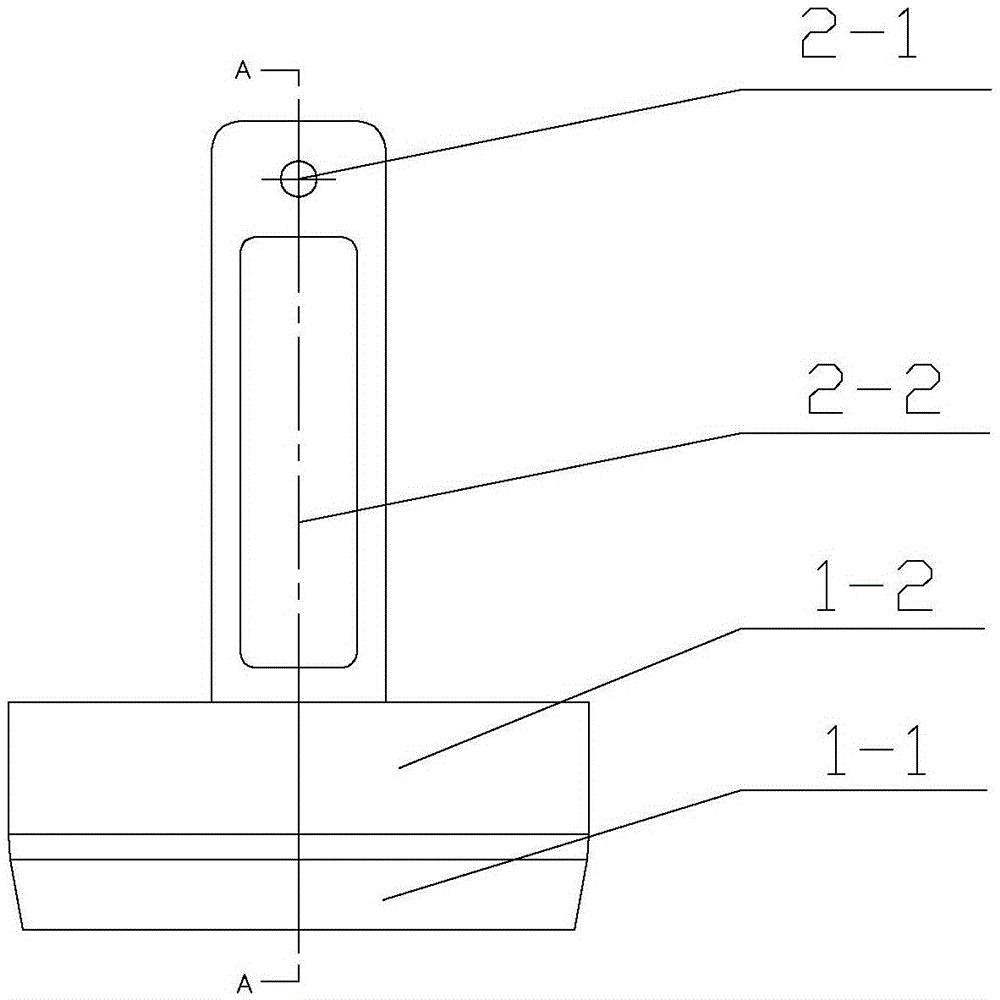

[0015] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment, a support device for anti-deformation welding of thin-walled pipe fittings in this embodiment, which includes a support 1, a handle 2 and a lifting rod 3, and the support 1 includes a circular platform section 1-1 and a cylindrical section 1-2, the large end of the round table section 1-1 is fixedly connected to one end of the cylindrical section 1-2, the handle 2 is a cuboid member, one end of the handle 2 is fixedly connected to the other end of the cylindrical section 1-2, and the handle 2 The other end of the handle is processed with a circular through hole 2-1, and the handle 3 is worn in the circular through hole 2-1 on the handle 2.

[0016] The first pipe 10 is fixed, the support 1 of the support device of the present invention is put into the first pipe 10, the circular platform section 1-1 of the support 1 is in contact with the inner conical surface of one end of the fir...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination Figure 1 to Figure 6 To illustrate this embodiment, the diameter of the large end of the circular frustum segment 1-1 is the same as that of the cylindrical segment 1-2. Such design ensures that the position of the first pipe fitting and the second pipe fitting is accurate when they are butt welded. Other compositions and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: combination Figure 1 to Figure 6 To illustrate this embodiment, the central axis of the circular through hole 2-1 is perpendicular to the central axis of the cylindrical section 1-2. With this design, the operator can exert less force during the process of withdrawing the supporting device after welding. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com