Water type multi-functional, hydrophobic, air-permeability and porous material, preparation method and application thereof

A hydrophobic, breathable and multi-functional technology, which is applied in the fields of building waterproofing, thermal insulation materials and building coatings. It can solve the problems of damaging the color stability of pigments in composite coatings, not being easy to finely polish and leveling, and not being able to block capillary water penetration. , to achieve the effect of improving the uniformity of brushing, significant beneficial effect, outstanding sandability and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

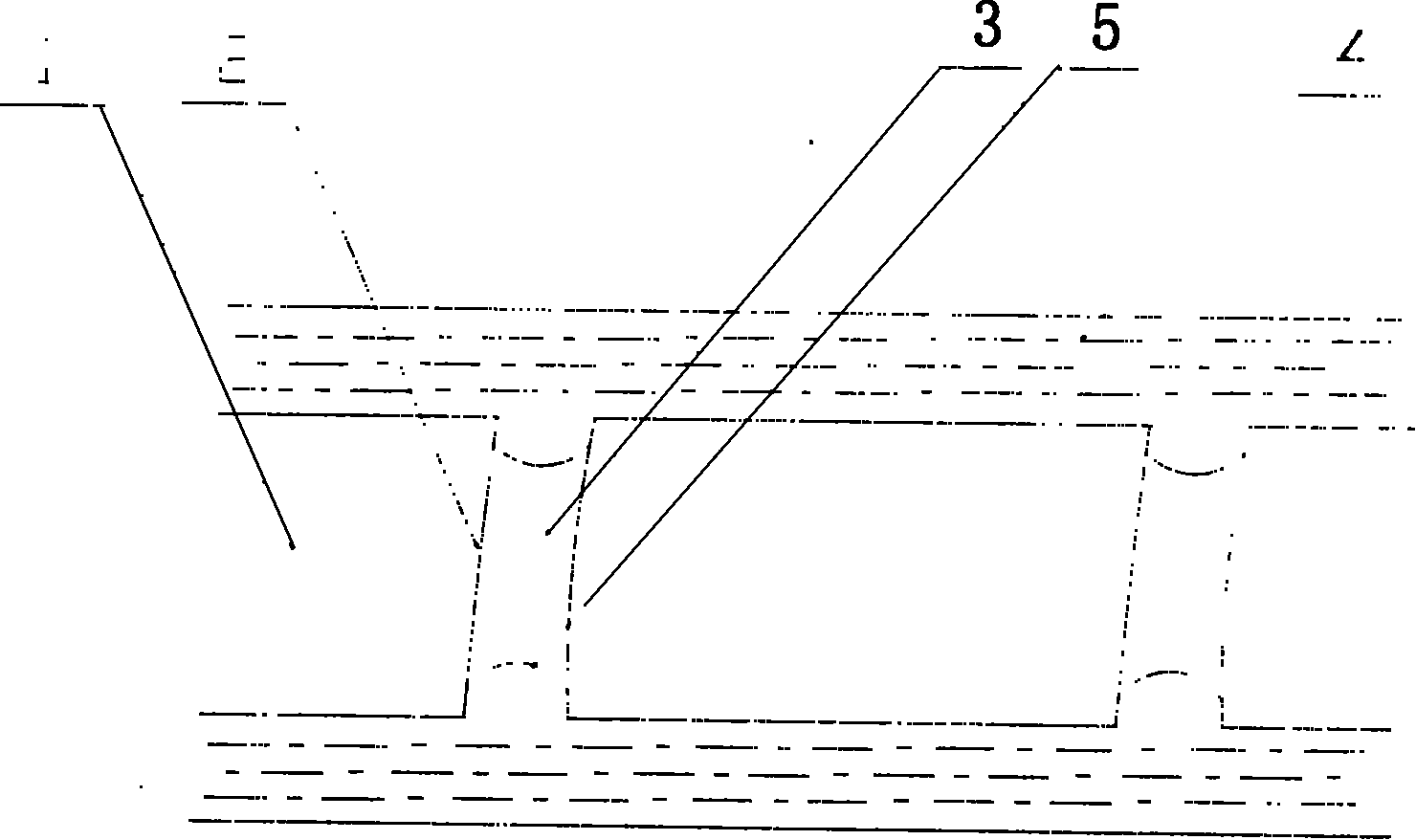

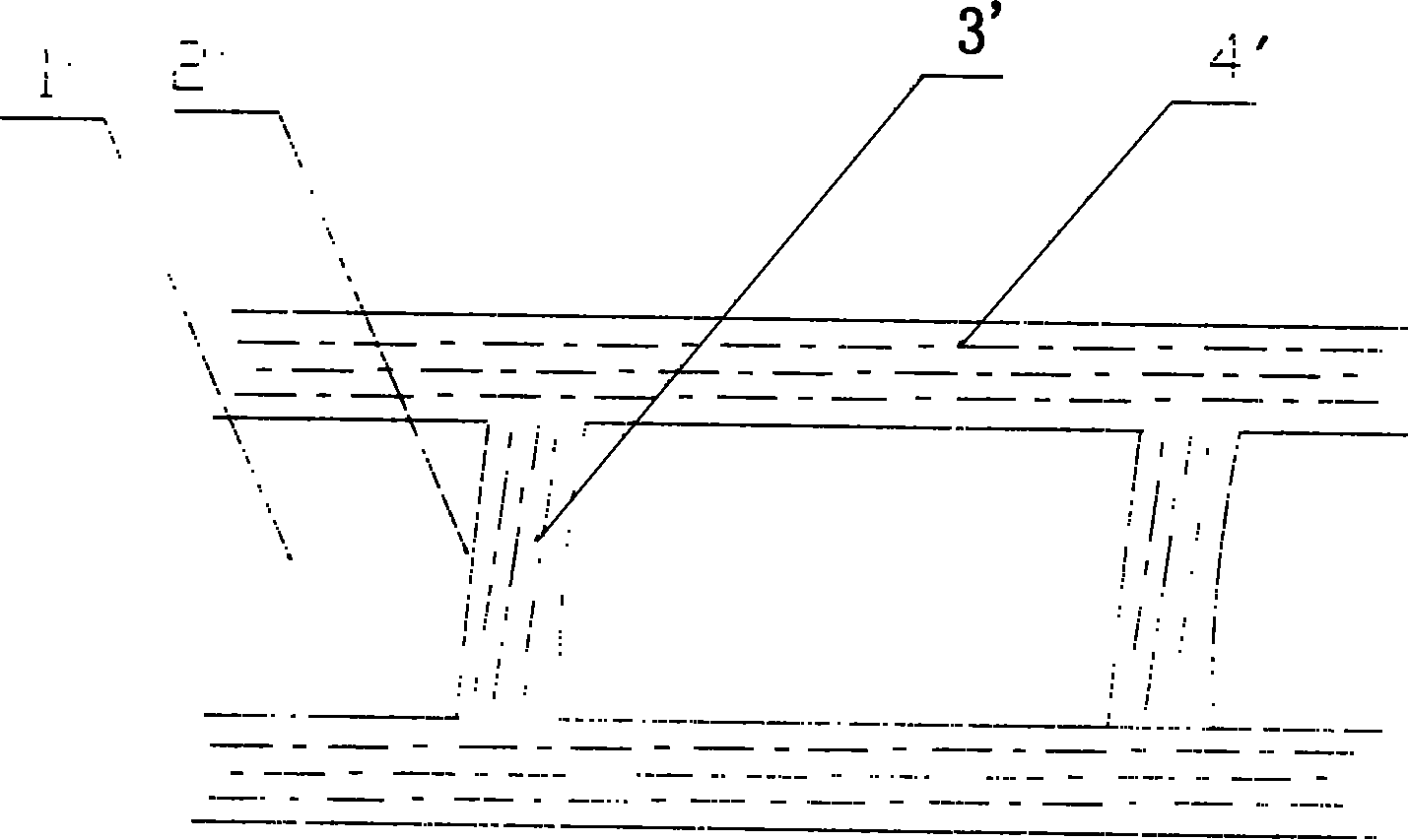

Image

Examples

Embodiment 1

[0044] Embodiment 1: the preparation of hydrophobic paste putty for building walls

[0045] A) Add 500 parts of 800 mesh ground calcium carbonate, 150 parts of 320 mesh talcum powder, and 30 parts of paraffin into a high-speed mixer, heat to 65 degrees Celsius, and mix at high speed for 30 minutes;

[0046] B) Add 270 parts of water and 4 parts of hydroxyethyl cellulose into the mixer, stir and dissolve into a clear colloid, then add 80 parts of styrene-acrylic emulsion, 3.5 parts of TEXANOL film-forming aid, 1 part of anti-fungal agent, and defoamer 2 parts, stir evenly, add the hydrophobic powder prepared in step A), and then stir evenly. After coating and drying, its performance is shown in Table 1.

Embodiment 2

[0047] Embodiment 2: the preparation of water-based building sealant

[0048] A) Add 200 parts of 800-mesh light calcium carbonate, 450 parts of 500-mesh calcite powder, 20 parts of paraffin and 10 parts of methyl silicone oil into a high-speed mixer, heat to 65 degrees Celsius, and mix at high speed for 30 minutes;

[0049] B) Add 200 parts of water and 4 parts of hydroxyethyl cellulose into the mixer, stir and dissolve into a clear colloid, then add 150 parts of elastic pure acrylic emulsion, 7.5 parts of TEXANOL film-forming aid, 1 part of antifungal agent, defoaming agent 2 parts of agent, after stirring evenly, add the hydrophobic powder prepared in step A), after stirring evenly, add 5 parts of polypropylene fiber, after stirring evenly, vacuumize and defoam. After coating and drying, its performance is shown in Table 1.

Embodiment 3

[0050] Embodiment 3: Preparation of water-based thermal insulation and water-resistant mortar

[0051] A) Add 300 parts of 200 mesh heavy calcium carbonate, 150 parts of 60 mesh quartz powder, 300 parts of expanded perlite powder, and 30 parts of polyethylene wax into a high-speed mixer, heat to 85 degrees Celsius, and mix at high speed for 30 minutes;

[0052] B) Add 200 parts of water and 4 parts of hydroxyethyl cellulose into the mixer, stir and dissolve into a clear colloid, then add 150 parts of styrene-acrylic emulsion, 7.5 parts of TEXANOL film-forming aid, 1 part of anti-fungal agent, and defoamer 2 parts, stir evenly, add the hydrophobic powder prepared in step A), and then stir evenly. After coating and drying, its performance is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com