Gantry crane large pinwheel manufacturing accuracy control method

A portal crane, manufacturing precision technology, applied in manufacturing tools, welding equipment, metal processing equipment, etc. Manufacturing accuracy and other issues to achieve the effect of reducing construction difficulty, ensuring accuracy and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

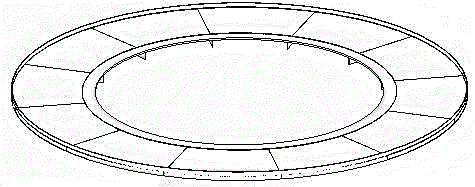

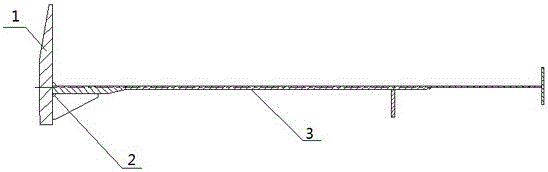

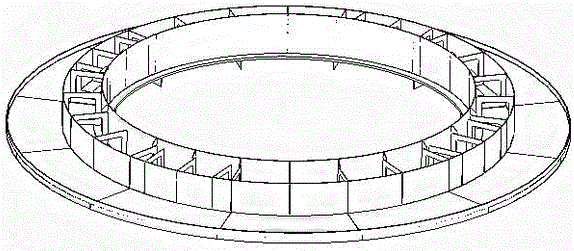

[0021] The structural diagram of a method for controlling the manufacturing accuracy of a large needle wheel of a crane shown in the accompanying drawings is specifically described as follows: a method for controlling the manufacturing accuracy of a large needle wheel of an eight-strut type portal crane, the specific steps are:

[0022] ①a) The welding of the bottom circular plate and the outer ring plate is reversed;

[0023] b) Release the ground sample on the level ground;

[0024] c) Tailor welding each half of the cylinder into a whole cylinder;

[0025] d) Assembly cylinder;

[0026] e) Welding square ribs, there are 32 square ribs divided equally;

[0027] f) Weld the cover plate and the small ribs on the cover plate to complete the internal welding;

[0028] g) Weld the pin ring plate in the middle layer, and then weld the upper and lower rib plates;

[0029] h) After the NDT is qualified, the overall level is found, and the line is marked: the track ring surface, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com