Tubular pile welding vehicle capable of being mounted and dismounted quickly and provided with locking track

A welding car and welding trolley technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of pre-tightening force dependence, guide rails can't hold the steel pipe tightly, confusion of operation and rotation direction, etc., and achieve reduction Prep work, reduced overall time, overall small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

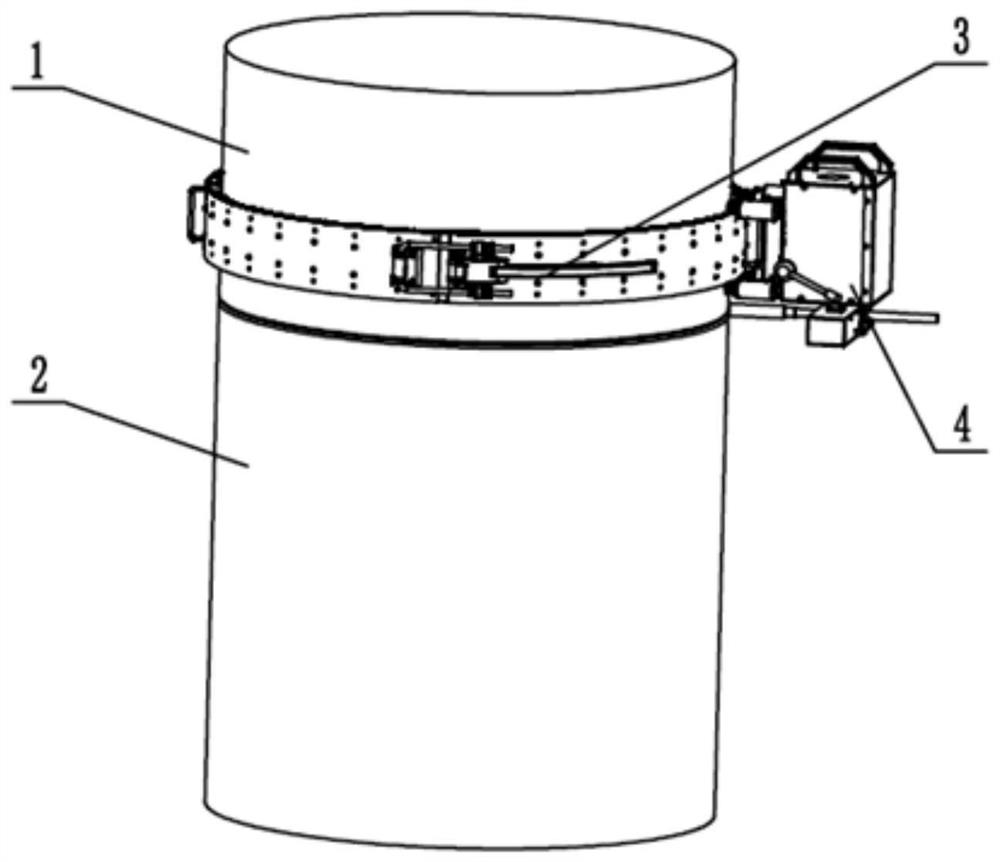

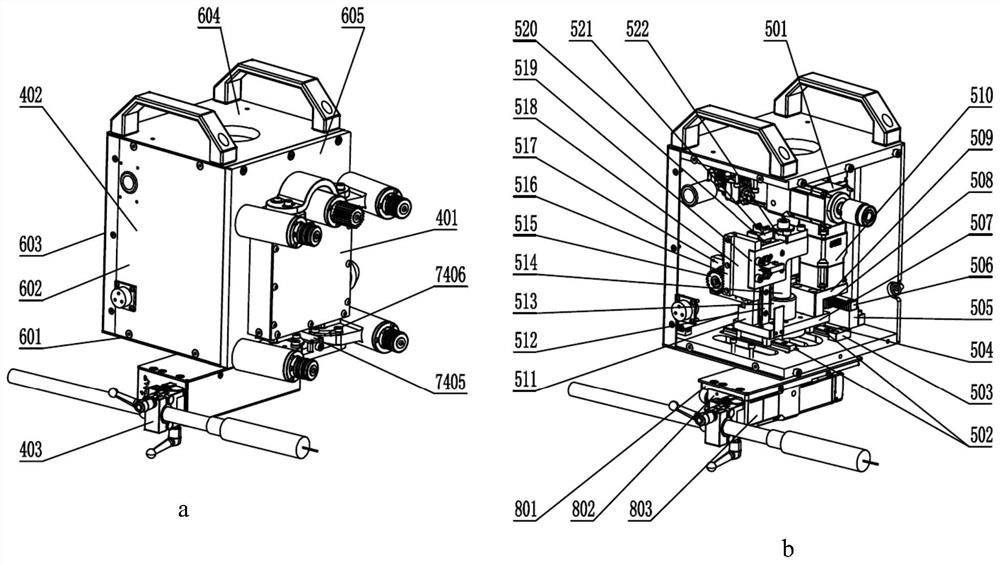

[0035] see figure 1 , the present invention provides a pipe pile welding vehicle with fast assembly and disassembly with locking track, the pipe pile welding vehicle with fast assembly and disassembly with locking track includes: fast locking track 3, welding trolley 4, control system (not shown out) and an operating handle (not shown); the welding trolley 4 includes a clamping mechanism 401, and the welding trolley 4 is clamped on the fast locking track 3 by the clamping mechanism 401; the control system Installed on the welding trolley 4 and connected with the welding trolley 4; the operating handle is connected with the control system for manipulating the welding trolley 4 by controlling the control system.

[0036] The pipe pile welding vehicle with fast assembly and disassembly with locking track of the present invention clamps the welding trolley 4 on the fast locking track through the clamping mechanism 401, without manual locking, which can ensure the safety of the wel...

Embodiment 2

[0039] Please combine figure 1 refer to Figures 2 to 6 , this embodiment also provides a quick assembly and disassembly pipe pile welding vehicle with a locking track. The specific structure of the quick assembly and disassembly pipe pile welding vehicle with locking track is roughly the same, the difference between the two is that the quick assembly and disassembly pipe pile welding vehicle with locking track described in this embodiment is compared with that in Embodiment 1 The quick assembly and disassembly pipe pile welding vehicle with locking track also includes the following specific structure.

[0040] As an example, the quick locking track 3 is tightly hugged on the upper pipe pile 1, and the upper pipe pile 1 is located on the lower pipe pile 2, as figure 1 shown.

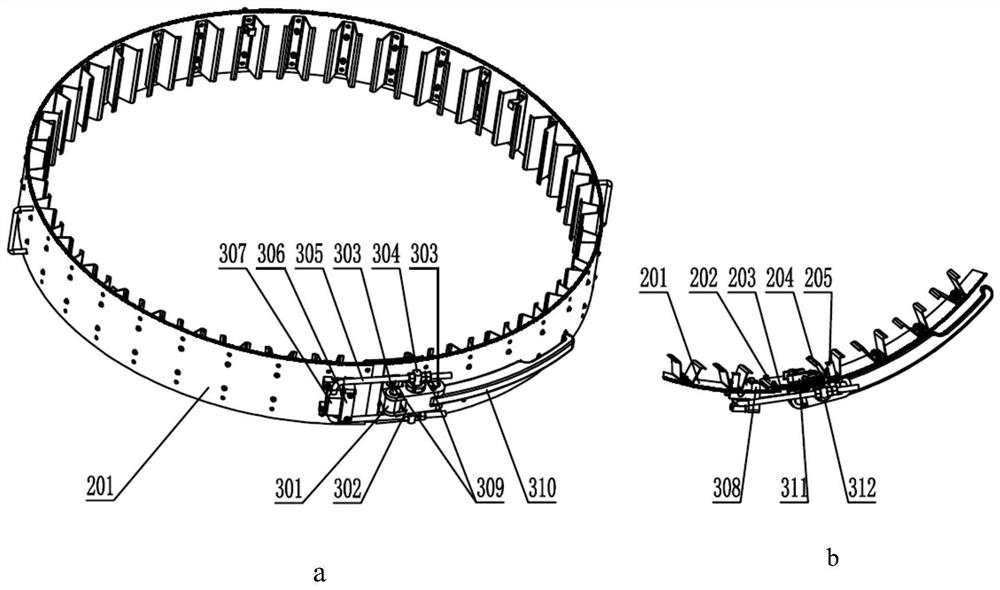

[0041] Specifically, such as figure 2 As shown, the quick locking track 3 includes a side tooth steel belt 201, a transition side tooth steel belt 202, a transition pad 203, an elastic device 204, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com