Orbital welding apparatus

A welding equipment, orbital technology, applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of independent control, not allowing welding head speed/acceleration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

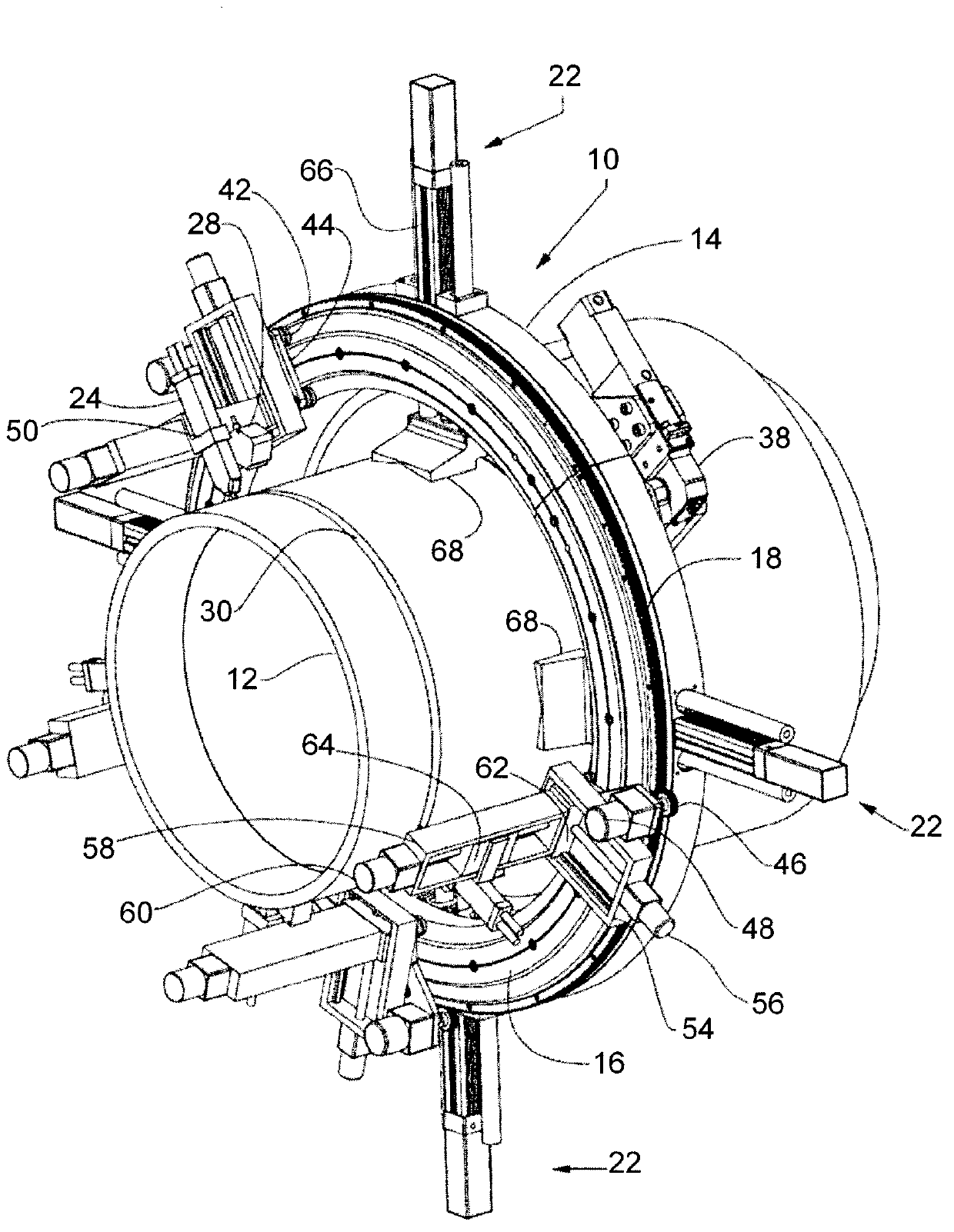

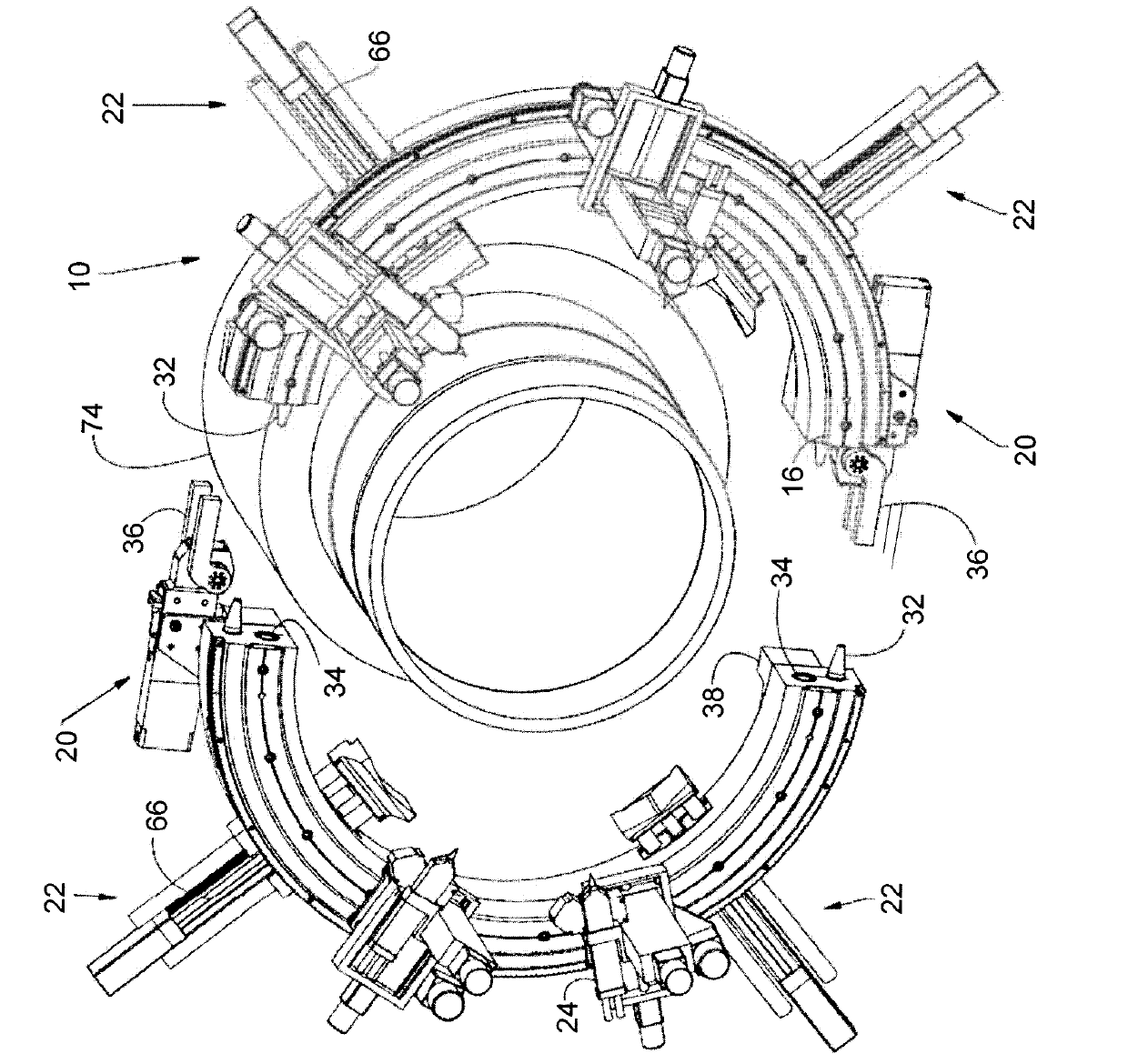

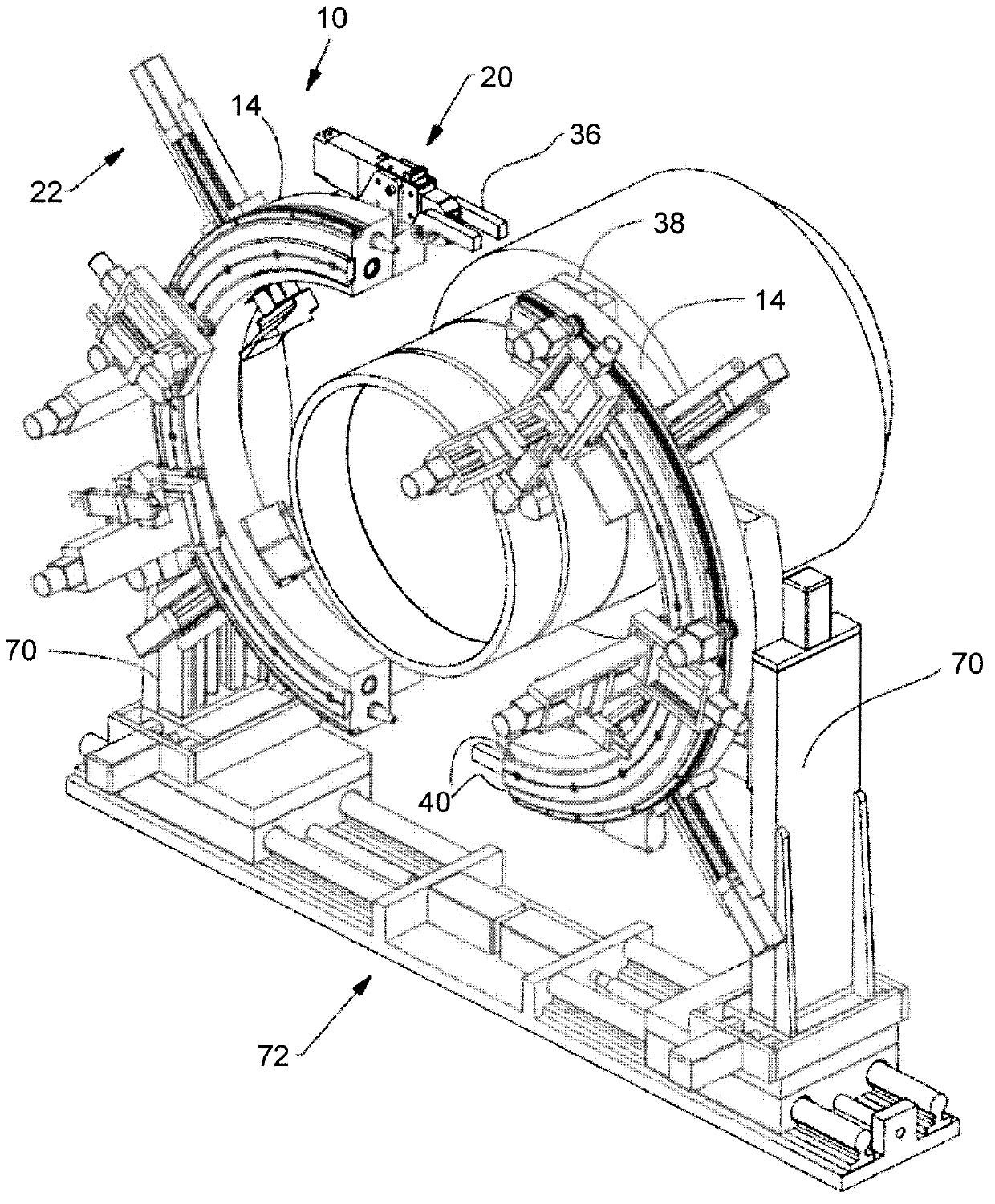

[0011] Such as figure 2 and image 3 As shown, the present invention is an orbital pipe welding apparatus 10 divided into two halves designed to orbit around figure 1 The pipe sections 12 are shown attached together. The orbital welding apparatus 10 generally includes two separate backing rings 14, a circular raceway 16, a circular ring gear 18, a locking device 20 for locking the two backing rings together, The device 10 in the welding position is fixed to and around the workpieces to be welded together (pipe sections 12), the device 22 is fixed around the workpieces to be welded together, the welding torch 24, the device 26 for holding the welding torch 24 and moving the welding torch 24 , and a scanning device 28 for scanning and tracking the welding area 30 .

[0012] Such as figure 2 and image 3 As shown, each collar 14 is semicircular and is provided with alignment means, such as a tapered pin 32 and a hole 34 for receiving said tapered pin 32 . This setting ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com