Manufacturing method of wrapper plate type side wall structure of wagon

A technology for side wall structures and railway wagons, applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of many arc-shaped welds, difficult welding, poor welding shape, etc., to reduce the number of rounding, reduce The number of arc-shaped welds and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The manufacturing method of the railway wagon cladding type side wall structure of the present invention, its steps are:

[0025] (1) Sheet uncoiling and pretreatment;

[0026] (2) Sheet blanking and leveling;

[0027] (3) Cutting and jigsawing of side wall panels;

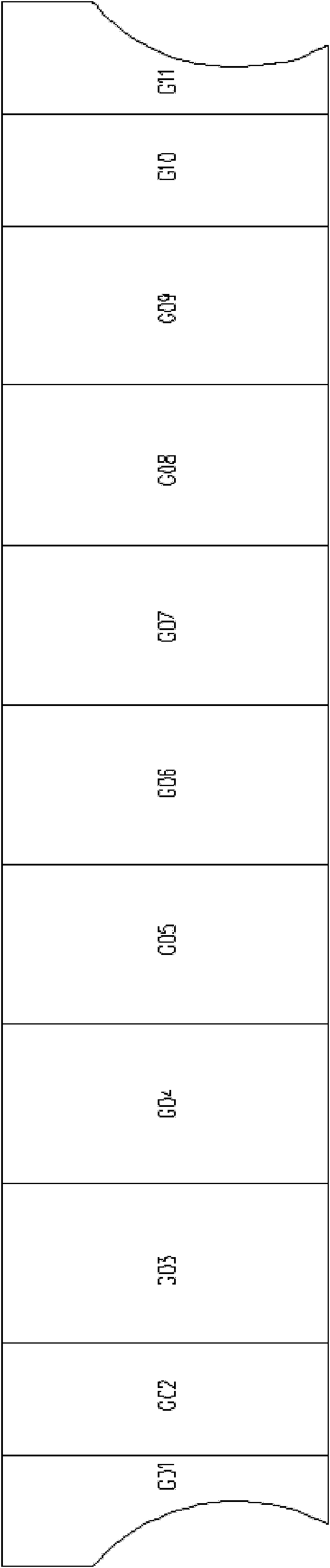

[0028] 1) According to the length and shape requirements of the side wall panels, cut N pieces of equal-length veneers G01, G02...G0N;

[0029] 2) Divide N equal-length veneers G01, G02...G0N into M groups in sequence, with 2 to 4 veneers in each group, and flat-weld several veneers in each group to form M large boards; N consists of The product length is divided by the sheet width to determine.

[0030] (4) Roll the M large slabs into M pieces of arc-shaped side wall panels respectively according to the required radian;

[0031] (5) Side wall assembly and welding:

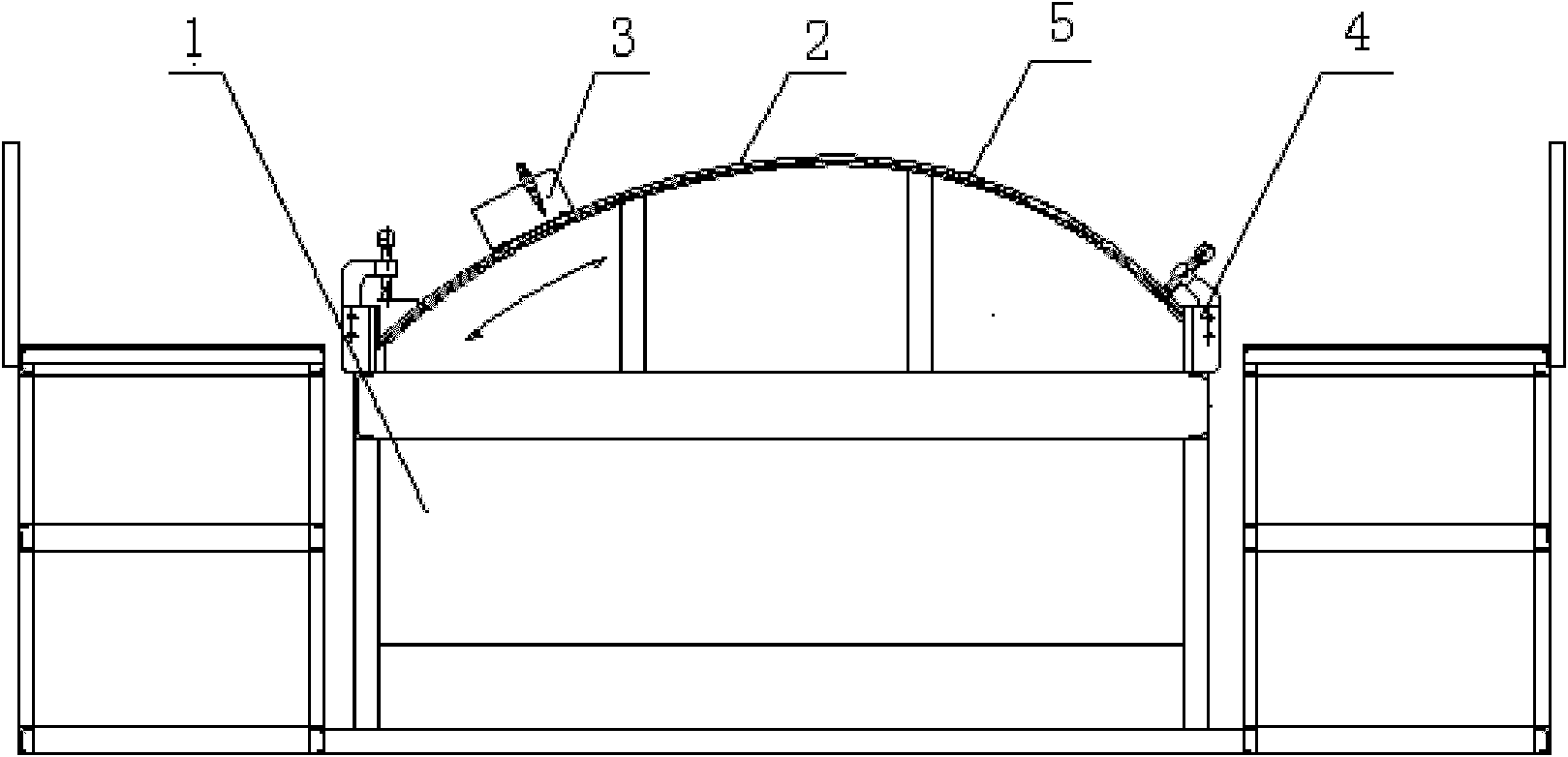

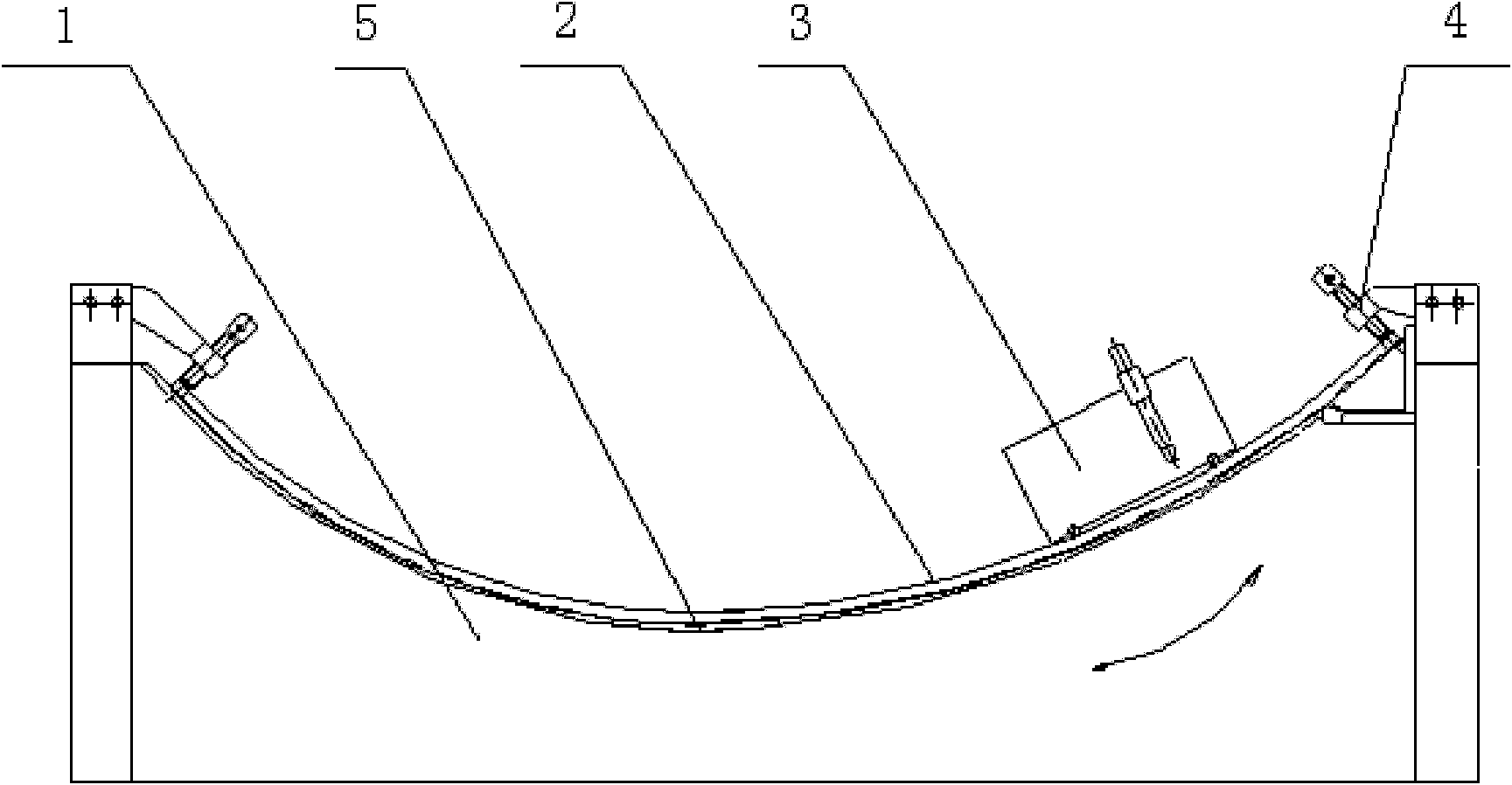

[0032] figure 2 It is a schematic diagram of the assembly and welding of the outer side of the side wall panel, image 3 It is a schem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com