Train track welding equipment

A technology for welding equipment and train tracks, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low welding efficiency and heavy welding equipment, and achieve the effect of improving work safety and work quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

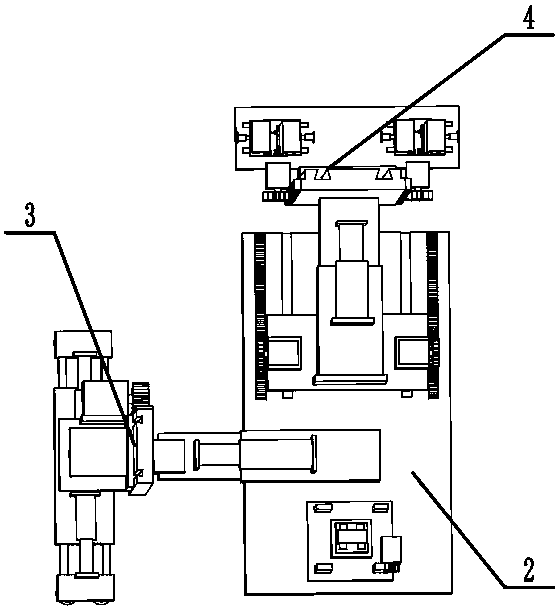

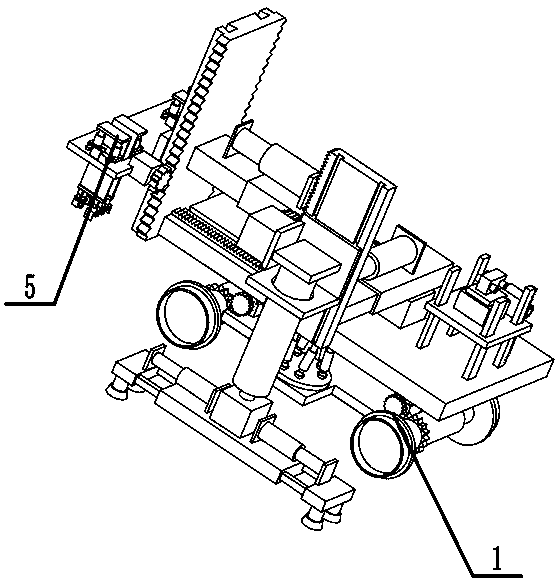

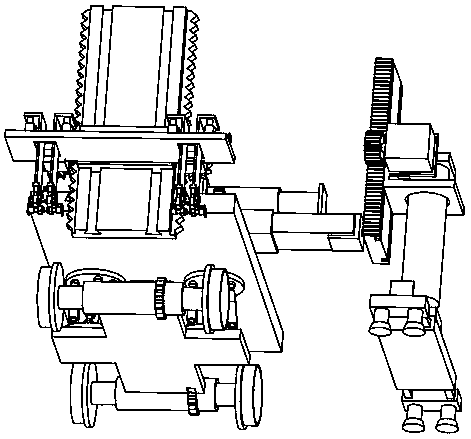

[0019] Example figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 Shown, a kind of train track welding equipment comprises walking part 1, base 2, support part 3, welding part pushing frame 4, four welding parts 5, it is characterized in that: the bottom plate 201 of described base 2 and walking part The two second parallel mechanism bottom plates 104 of 1 are fixedly connected; the motor shaft of the first steering gear 204 of the base 2 is fixedly connected with the bottom of the first telescopic sleeve 301 of the support part 3; the welding part pushes The two sliders 404 of the frame 4 are respectively slidably installed in the two first dovetail grooves 202 of the base 2, the two fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com