Jig

A jig and clamping block technology, which is applied in the field of jigs, can solve problems such as damage to the main board, and achieve the effect of increasing efficiency and saving assembly time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to illustrate the technical content and structural features of the present invention in detail, the following will be described in detail in conjunction with the implementation and accompanying drawings.

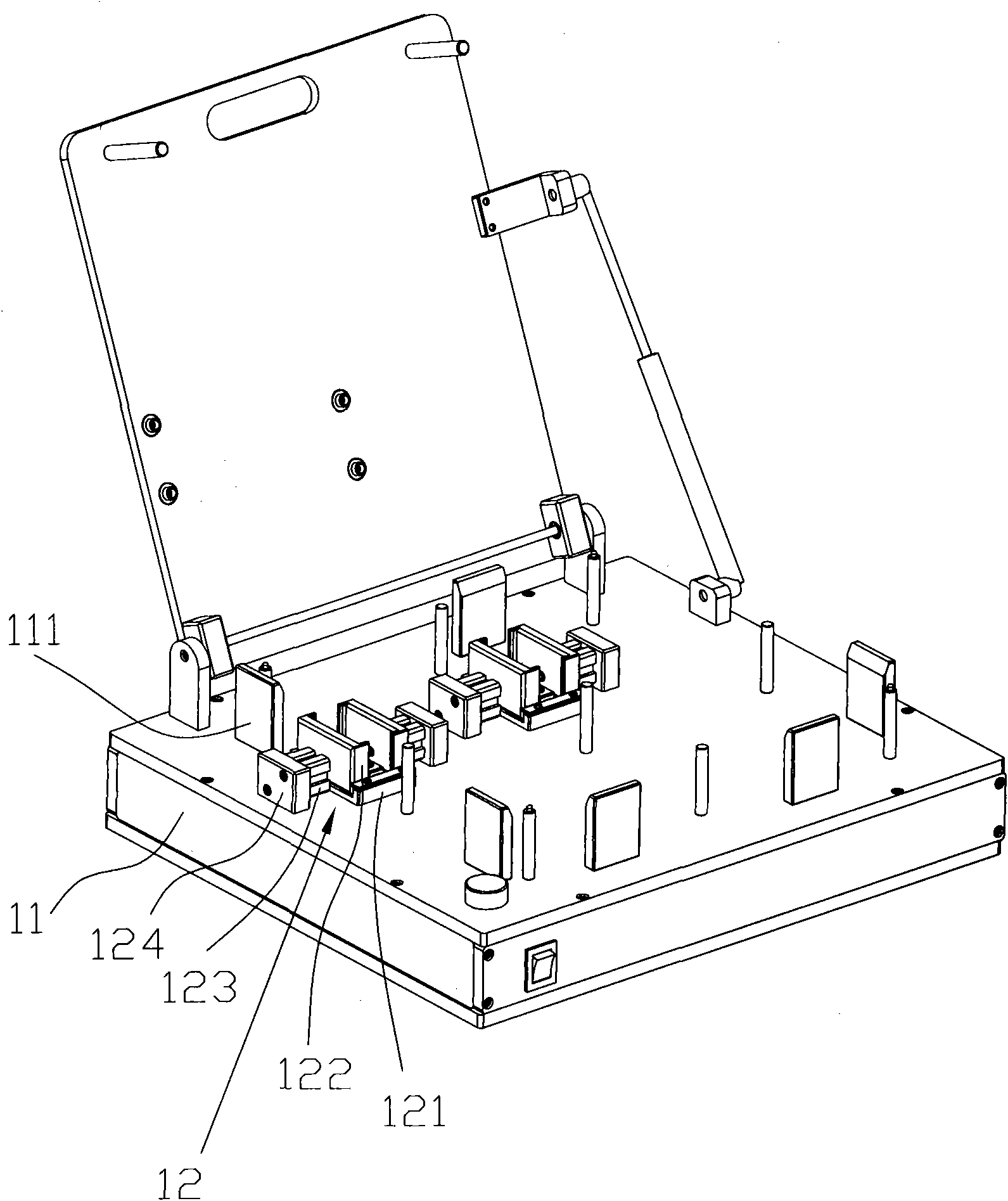

[0015] see figure 1 , is a three-dimensional assembly diagram of a preferred embodiment of the jig of the present invention. The jig includes a main box 11 provided with a circuit control device (not shown) and at least one positioning device 12 for clamping a radiator (not shown). Wherein, the main box 11 is provided with four baffles 111 for positioning the main board.

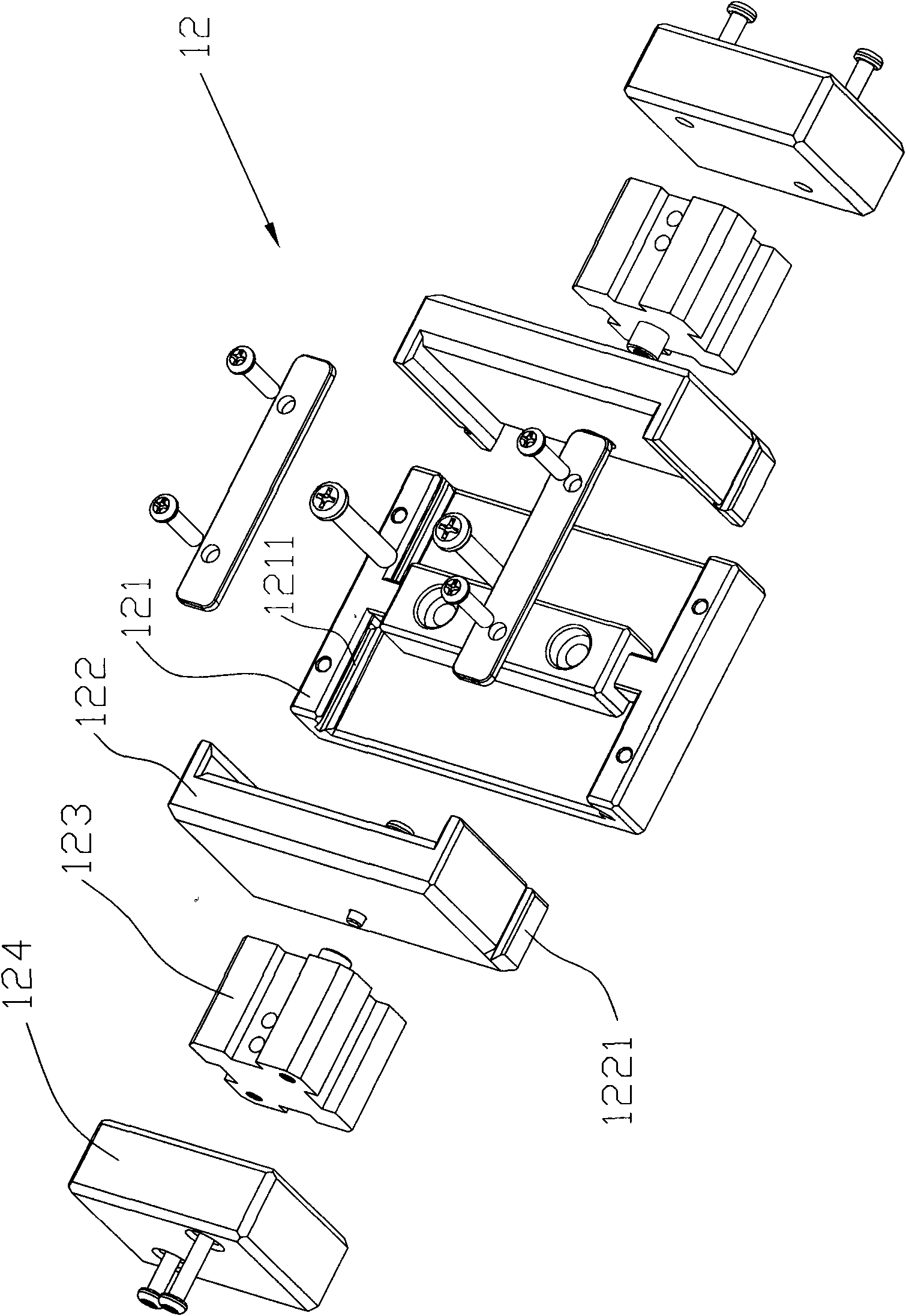

[0016] see again figure 2 , is a three-dimensional exploded schematic view of the positioning device of the jig of the present invention. The positioning device 12 includes: a concave guide positioning part 121, which is locked on the main box body 11 through a screw assembly, and guide grooves 1211 are provided on the opposite sides of the two side walls; two clamping blocks 122, each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com